Instant use side plate connecting hole structure of storage cabinet

A locker and connecting hole technology, which is applied in the field of side plate connecting hole structure, can solve problems such as tilting or even falling of the cabinet row, time-consuming and laborious assembly, and inconvenient transportation, so as to improve safety, secure connection, and improve visual experience effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

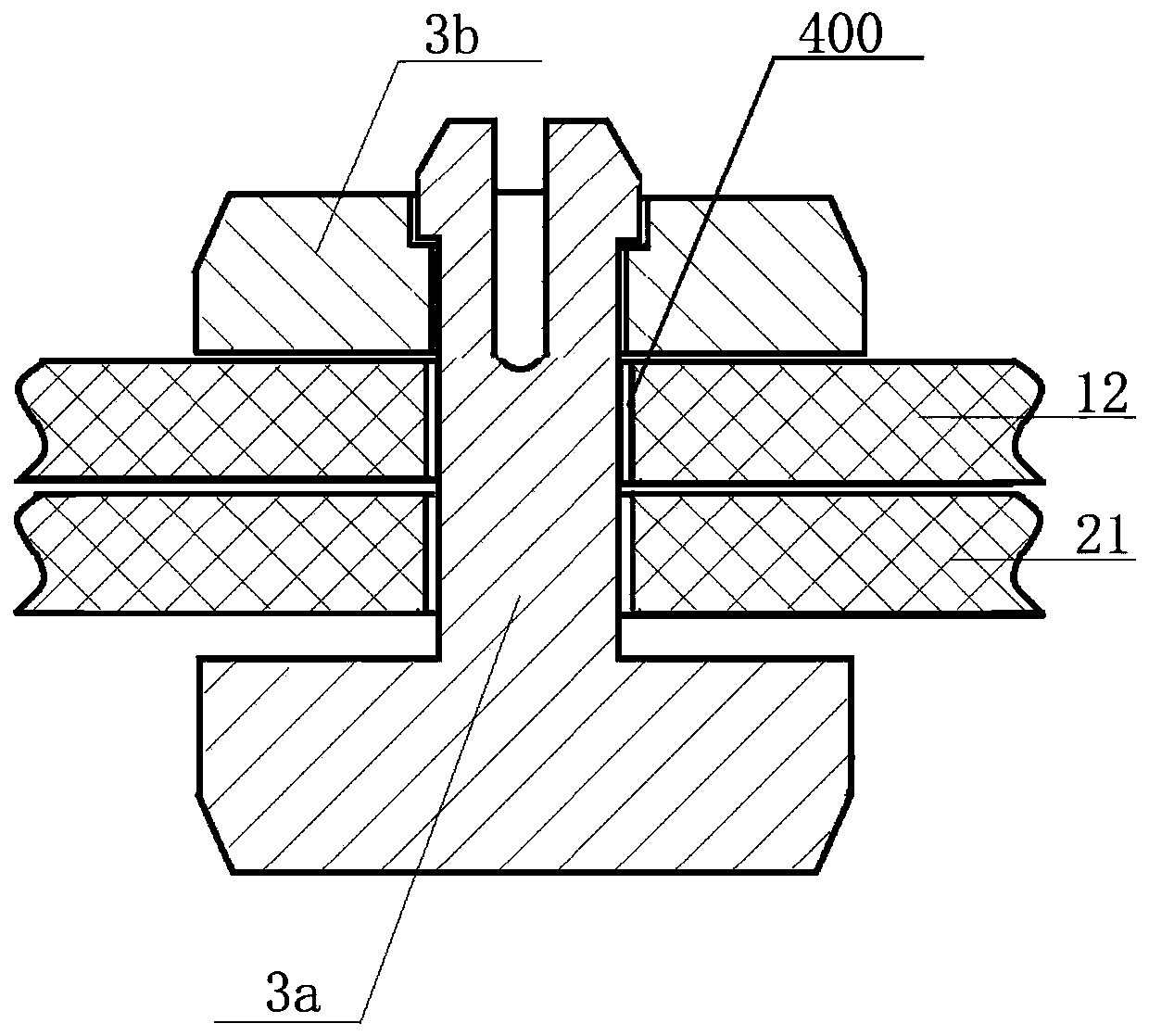

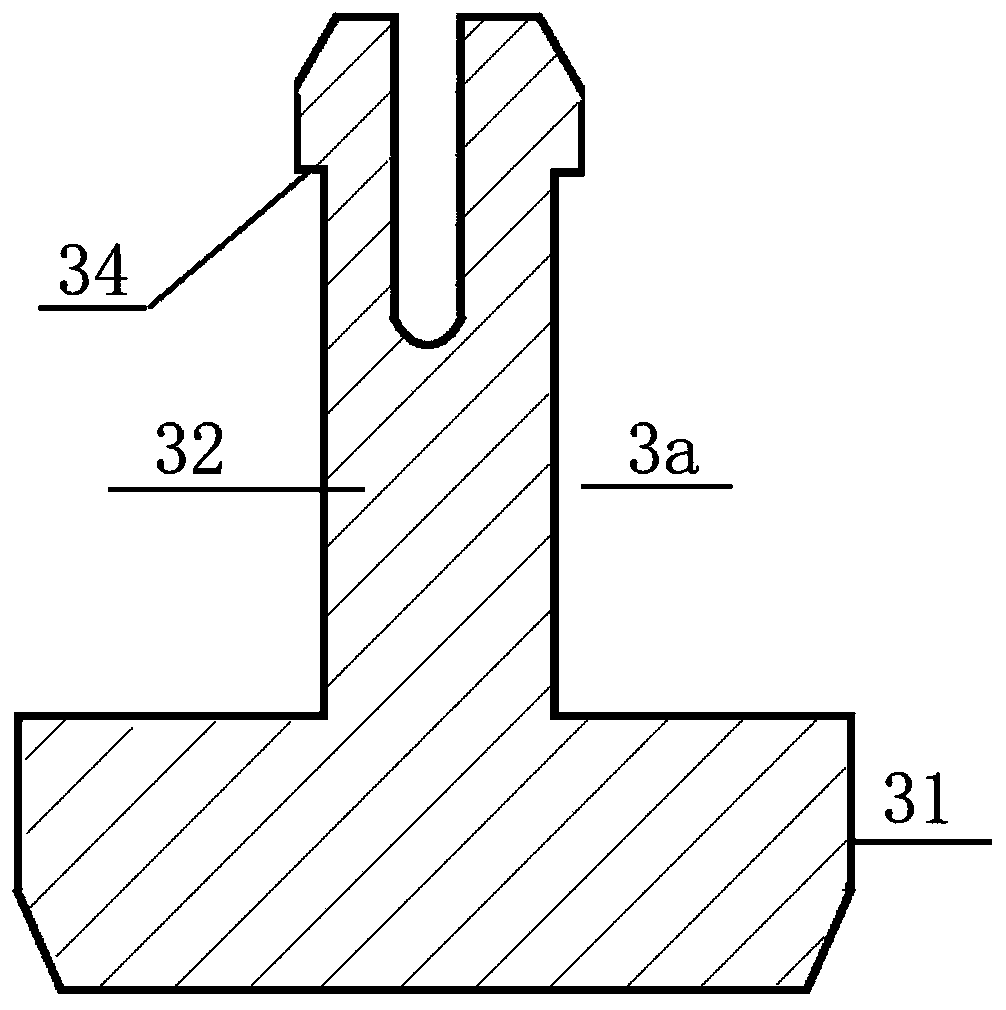

[0051] Firstly, each annular rib 403 is concentric with the corresponding circular sheet, and the ratio of its inner diameter to the diameter of the circular sheet is 1.2-3.5.

[0052] Its two, the difference between the inner radius and the outer radius of the annular reinforcing rib 403 is 1-7mm, preferably 2-4mm, and the height is 0.5-5mm, preferably 1.5-3mm, and its inner diameter is the same as the diameter of the circular sheet The ratio is 2.0-2.8, preferably 2.3-2.5.

[0053] Third, the ratio of the thickness of each circular sheet (ie the preformed part) to the thickness of the side plate is 0.2-0.8, preferably 0.3-0.5.

[0054] Fourth, each annular reinforcing rib 403 is an arc-shaped surface, which has a better effect of preventing warped skin from cracking.

[0055] The present invention obtains the connecting hole 400 through the following implementation manners, specifically as follows:

[0056] During implementation, according to the requirements of the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com