Walking type set-shaped steel framework and installation method for T-beam framework.

An installation method and technology of shaped steel, applied in the direction of mold fixtures, molds, ceramic molding machines, etc., can solve the problems of increased construction costs, cumbersome procedures, and high costs, and achieve the effects of saving construction costs, simplifying the installation process, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

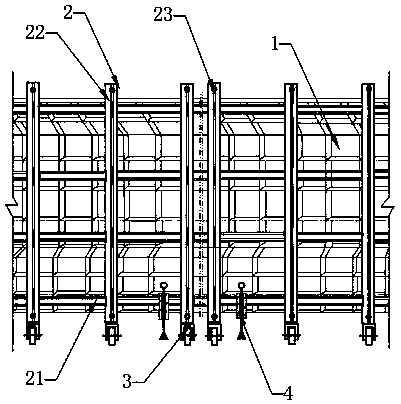

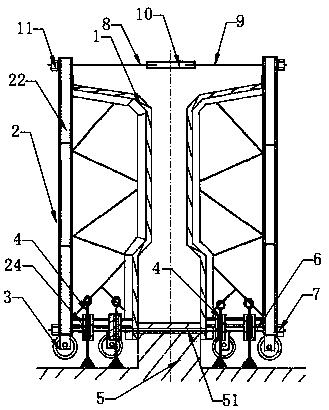

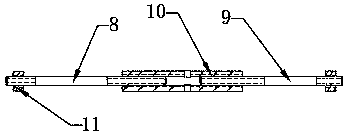

[0025] The walking type shaped steel formwork provided in this embodiment includes a steel side form, and a support 2 for supporting and reinforcing the steel side form is installed on the outside of the steel side form 1, the upper end of the support 2 is fixedly connected with the steel side form, and the lower end A plurality of traveling wheels 3 are installed; a plurality of jacking devices 4 for jacking up the steel side forms are installed at intervals at the lower end of the support 2 .

[0026] The bracket 2 includes a plurality of horizontal back braces 21, vertical back braces 22 and radial back braces 24. One end of the horizontal back braces is fixed on the outside of the steel side form 1, and the other end is fixed to the vertical back braces 22. The vertical back braces The upper end of 22 is fixed on the upper end of the steel side form 1 and extends out of the steel side form, the lower end is fixed with the radial back support 24 and extends out of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com