Method and system for treating waste hydrochloric acid

A treatment method and technology for waste hydrochloric acid, applied in the directions of iron halide, iron oxide/iron hydroxide, etc., can solve the problems of high cost and large amount of fuel, and achieve the effect of low system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

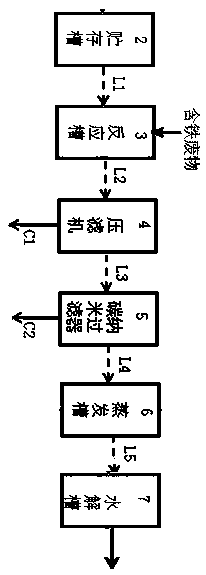

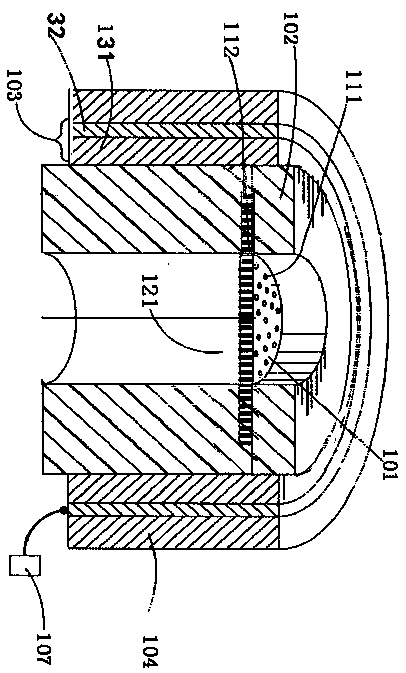

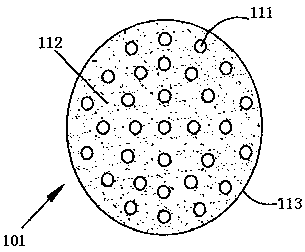

[0016] figure 1 It is a block diagram of the composition of the processing system of waste hydrochloric acid provided by the invention, as figure 1 As shown, the processing system 1 of the waste hydrochloric acid provided by the present invention comprises: a storage tank 2, a reaction tank 3, a filter press 4, a carbon nanofilter 5, an evaporation tank 6 and a hydrolysis tank, wherein the storage tank 2 is used to store waste Hydrochloric acid L1; reaction tank 3 is used to make waste hydrochloric acid L1 react with medicinal liquid to generate ferric chloride solution L2; described filter press 3 is used to separate the solution L2 provided by the reaction tank into solid matter C1 and filtrate L3; Carbon nanofilter 5 is used for filtering filtrate L3, generates solid matter C2 and ferric chloride solution L4; Evaporation tank 6 is used for evaporating the moisture content in ferric chloride solution, makes the trichlor in ferric chloride aqueous solution The iron oxide con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com