Preparation and application of a multifunctional poss type silicone curing agent

A multifunctional, organosilicon technology, applied in the fields of chemical industry and organic polymer materials, which can solve the problems of unsatisfactory POSS dispersion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 41ml of tetramethylammonium hydroxide, 50.96ml of methanol, and 15ml of water into a 500ml round bottom flask, stir in an ice bath, then add 22ml of tetraethoxysilane (0.1mol), and stir at room temperature for 24h. Afterwards, the mixture was added dropwise into another 1L three-necked flask (300ml of n-hexane and 42.9ml of 0.1mol dimethylchlorosilane had been added to the flask) under ice-bath conditions. The mixture was stirred at room temperature for 3 h. Finally, use a pear-shaped funnel to separate the liquid, take the upper layer liquid, spin evaporate, filter it with suction, wash it with methanol for 3 times, and get a white powder solid, dry it, and then get the raw material Si 8 o 12 (OSi(CH 3 ) 2 h) 8 .

[0039] Take 2g of the above-mentioned raw material POSS and put it into a 100ml three-necked flask, then add 30ml of toluene, add 0.04g of Pt catalyst dropwise, and stir at room temperature for 30min with nitrogen gas, then add 0.76g of absolute ethan...

Embodiment 2

[0042] Prepare Si according to the method in embodiment 1 8 o 12 (OSi(CH 3 ) 2 h) 8 Raw materials, take 2g of raw materials and put them into a 100ml three-necked flask, then add 30ml of toluene, add 0.04g of Pt catalyst dropwise, and stir at room temperature for 30min with nitrogen gas, then add 1.52g of absolute ethanol, react at 40°C for 24h, add activated carbon, and after ultrasonication for 1h, Suction filtration, rotary evaporation can obtain Si 8 o 12 (OSi(CH 3 ) 2 OCH 2 CH 3 ) 8 .

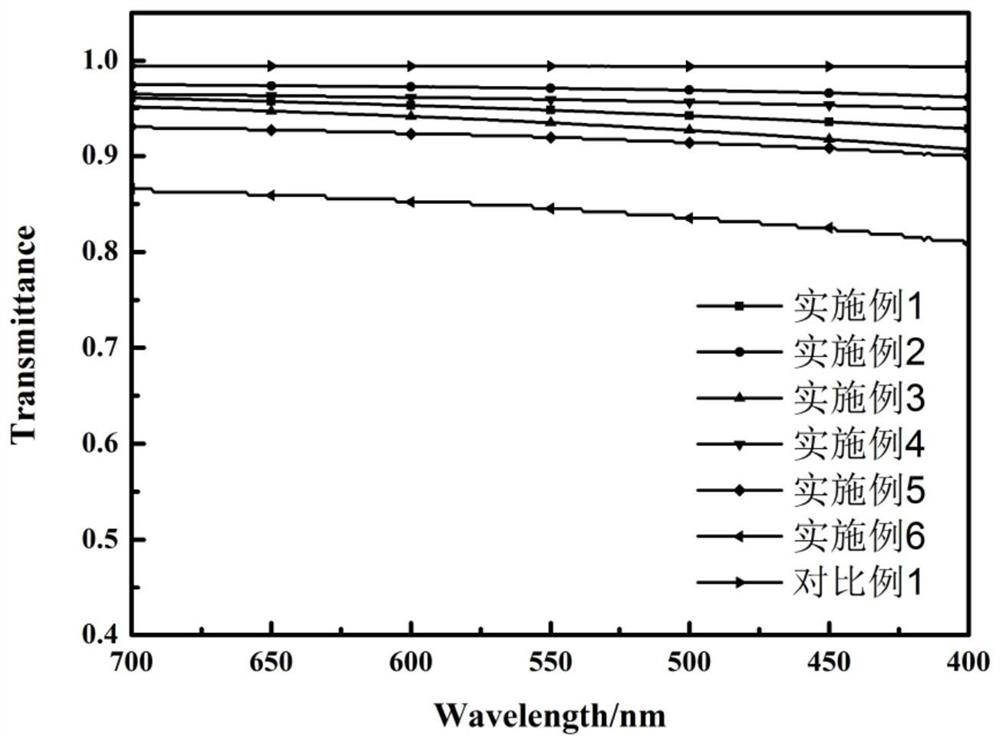

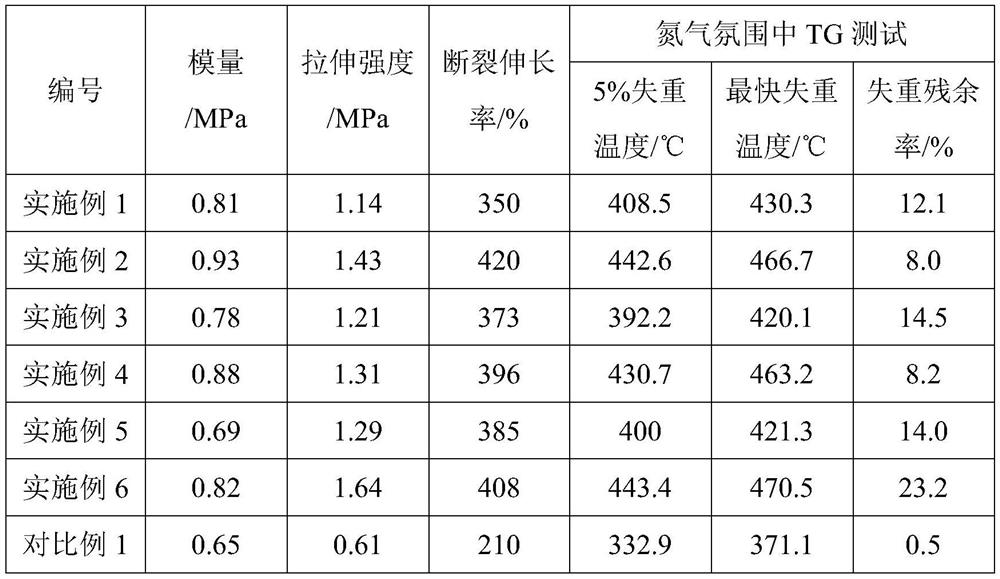

[0043] Prepare condensation type RTV silicone rubber according to the method of Example 1, except that the polyfunctional group POSS type silicone curing agent is prepared in this example, other formulations are the same as Example 1, and the properties of the gained silicone rubber are shown in Table 1 and figure 1 .

Embodiment 3

[0045] Prepare Si according to the method in embodiment 1 8 o 12 (OSi(CH 3 ) 2 h) 8 Raw material, take 2g of raw material and put it into a 100ml three-necked flask, then add 30ml of ether, add 0.02g of Pt catalyst dropwise, and stir at room temperature for 30min with nitrogen gas, then add 0.40g of anhydrous methanol, react at 40°C for 12h, add activated carbon, and ultrasonicate for 1h, Suction filtration, rotary evaporation can obtain Si 8 o 12 (OSi(CH 3 ) 2 h) 5 (OSi(CH 3 ) 2 OCH 3 ) 3 . The NMR characterization results of the product are:

[0046] Prepare condensation type RTV silicone rubber according to the method of Example 1, except that the polyfunctional group POSS type silicone curing agent is prepared in this example, other formulations are the same as Example 1, and the properties of the gained silicone rubber are shown in Table 1 and figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com