Visible-light ultra-spectrum sensitized near-infrared-luminescence fluorescent powder and preparation method thereof

An ultra-broadband, phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of large absorption and emission reabsorption, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Cr 3+ , Er 3+ Co-doped La 3 Ga 5.5 Nb 0.5 o 14 The preparation of inorganic fluorescent powder material comprises the following steps:

[0024] a) Weigh an appropriate amount of La respectively 2 o 3 , Ga 2 o 3 ,Nb 2 o 5 ,Cr 2 o 3 ,Er 2 o 3 , so that Er 2 o 3 The doping concentration of 0.07, Cr 2 o 3 The doping concentration is 0.005, and each component is accurately weighed according to the stoichiometric ratio.

[0025] b) Fully mix and grind the components in step a) in an agate mortar, first dry grind and mix evenly, and then add alcohol for wet grinding to improve mixing efficiency and particle size distribution uniformity.

[0026] c) Put the uniformly mixed powder in step b) into the muffle furnace, first pre-calcine at 950°C for 4 hours, then pre-calcine at 1200°C for 4 hours, and finally calcinate at 1300°C for 5 hours, and each pre-calcination is completed. Grind thoroughly.

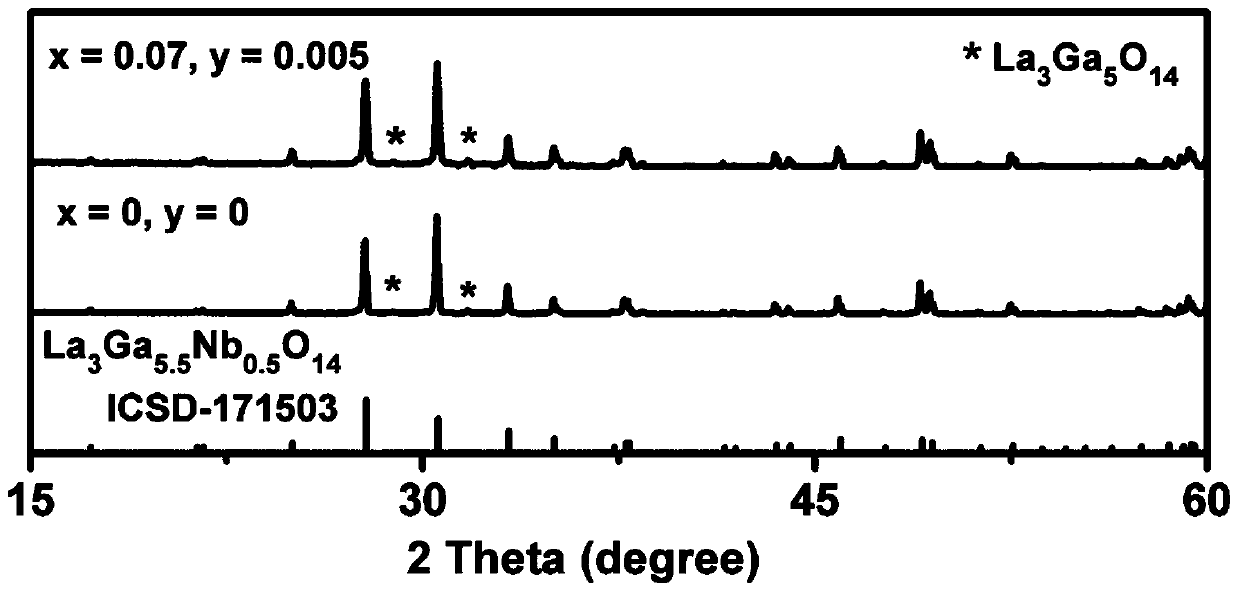

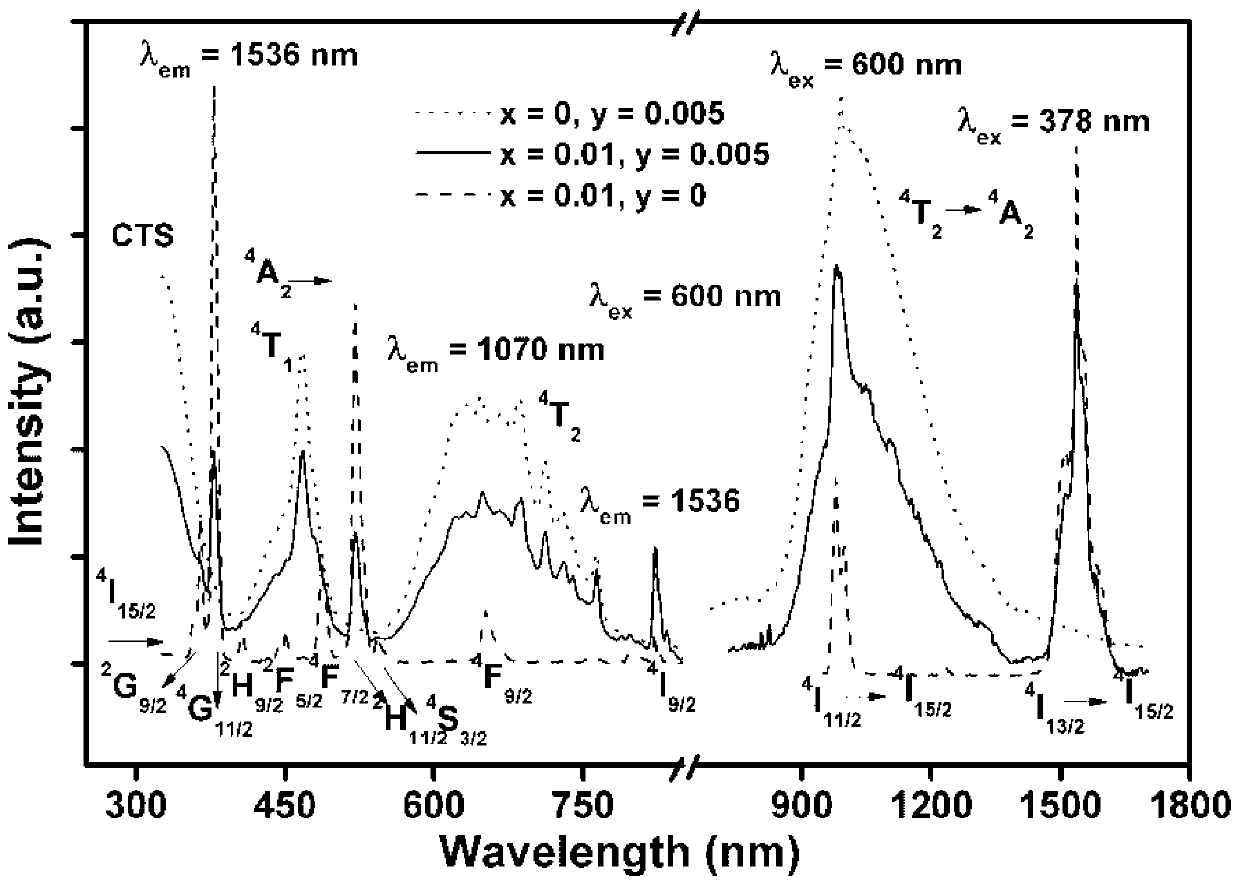

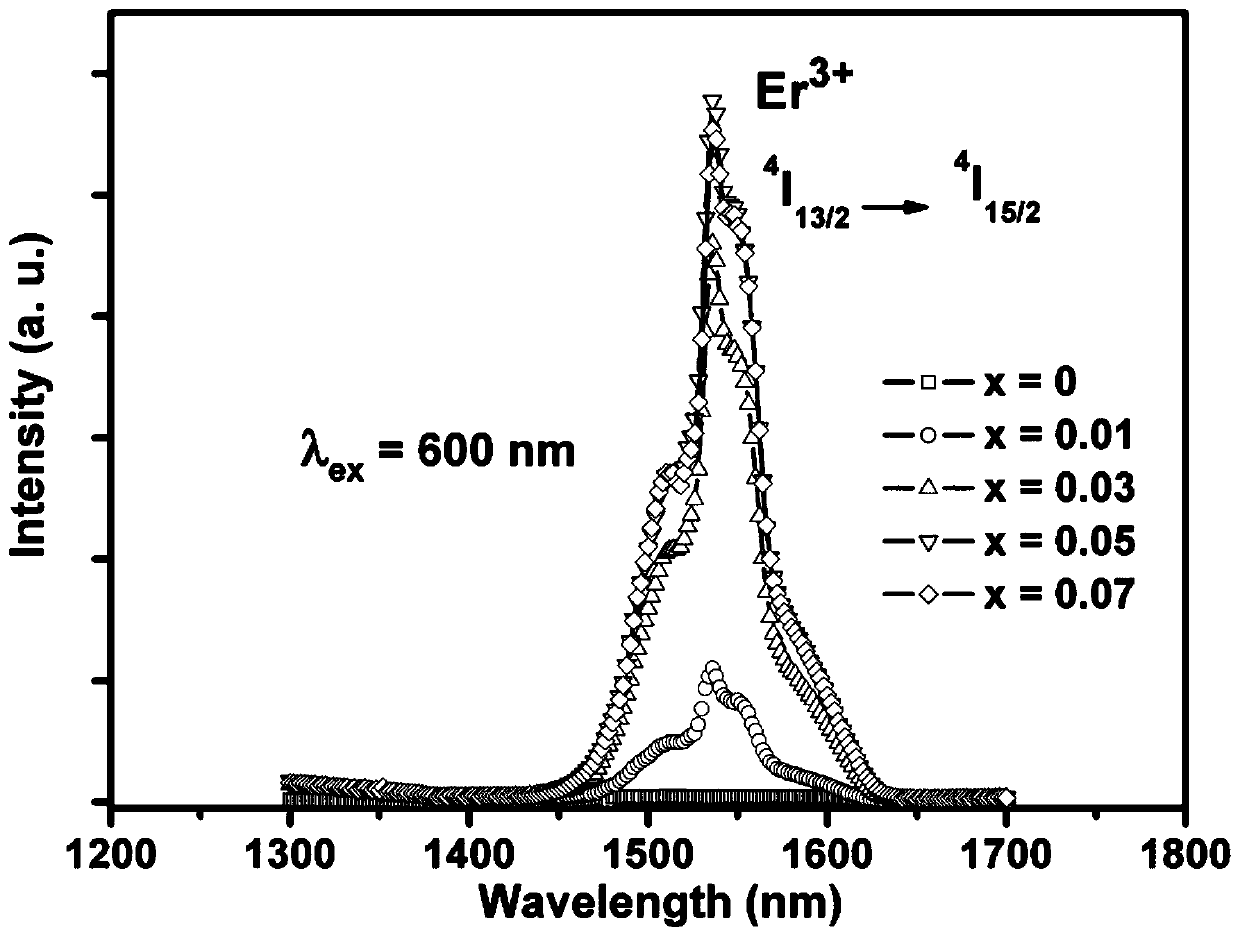

[0027] Reference attached figure 1 , the fluorescent powder o...

Embodiment 2

[0029] Cr 3+ , Er 3+ Co-doped La 3 Ga 5.5 Nb 0.5 o 14 The preparation of inorganic fluorescent powder material comprises the following steps:

[0030] a) Weigh an appropriate amount of La respectively 2 o 3 , Ga 2 o 3 ,Nb 2 o 5 ,Cr 2 o 3 ,Er 2 o 3 , so that Er 2 o 3 The doping concentration of 0.01, Cr 2 o 3 The doping concentration is 0.005, and each component is accurately weighed according to the stoichiometric ratio.

[0031] b) Fully mix and grind the components in step a) in an agate mortar, first dry grind and mix evenly, and then add alcohol for wet grinding to improve mixing efficiency and particle size distribution uniformity.

[0032] c) Put the uniformly mixed powder in step b) into the muffle furnace, first pre-calcine at 950°C for 4 hours, then pre-calcine at 1200°C for 4 hours, and finally calcinate at 1300°C for 5 hours, and each pre-calcination is completed. Grind thoroughly.

[0033] The result of XRD testing of the obtained fluorescent p...

Embodiment 3

[0035] Cr 3+ , Er 3+ Co-doped La 3 Ga 5.5 Nb 0.5 o 14 The preparation of inorganic fluorescent powder material comprises the following steps:

[0036] a) Weigh an appropriate amount of La respectively 2 o 3 , Ga 2 o 3 ,Nb 2 o 5 ,Cr 2 o 3 ,Er 2 o 3 , so that Er 2 o 3 The doping concentration of 0.03, Cr 2 o 3 The doping concentration is 0.005, and each component is accurately weighed according to the stoichiometric ratio.

[0037] b) Fully mix and grind the components in step a) in an agate mortar, first dry grind and mix evenly, and then add alcohol for wet grinding to improve mixing efficiency and particle size distribution uniformity.

[0038] c) Put the uniformly mixed powder in step b) into the muffle furnace, first pre-calcine at 950°C for 4 hours, then pre-calcine at 1200°C for 4 hours, and finally calcinate at 1300°C for 5 hours, and each pre-calcination is completed. Grind thoroughly.

[0039] Gained fluorescent powder is similar to embodiment 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com