A method for setting load current fault threshold

A technology of fault threshold and setting method, applied in electrical testing/monitoring, program loading/starting, instruments, etc., can solve problems such as setting threshold error, and achieve the effect of avoiding detection error, improving control accuracy, and improving diagnostic accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

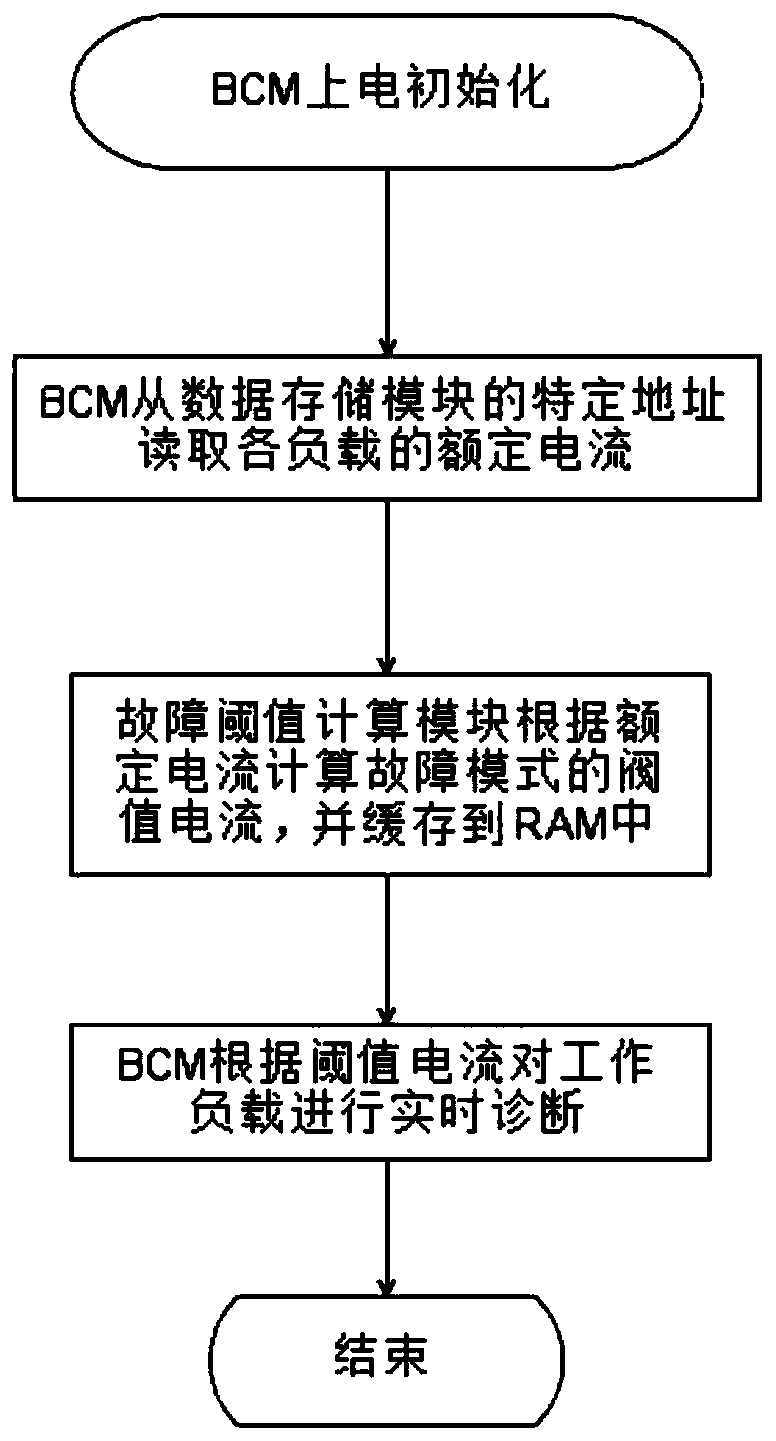

[0035] A method for setting a load current fault threshold, the method for setting the fault threshold comprises the following steps:

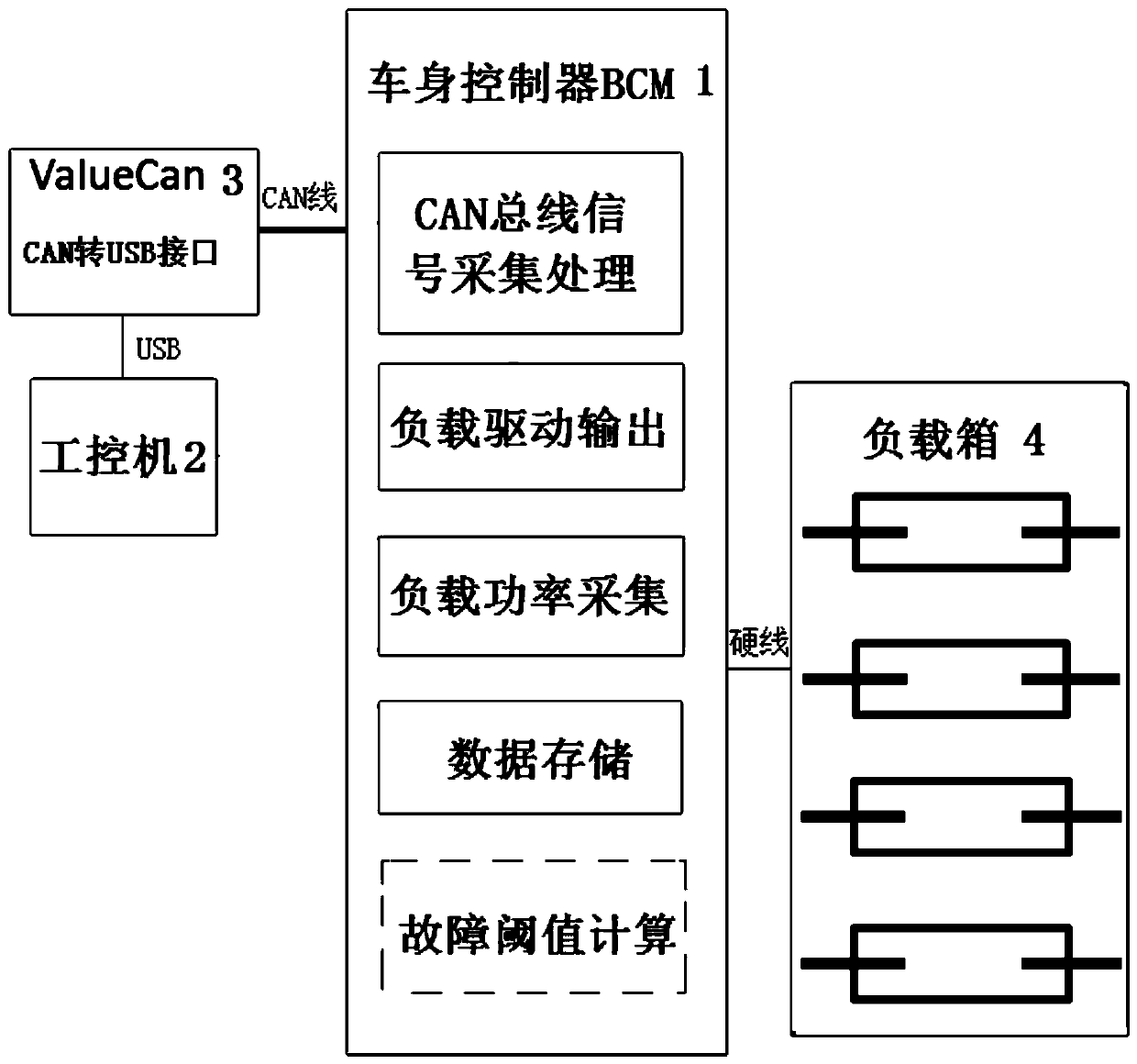

[0036] Step 1: Installation, connect the BCM1 with settings to the ValueCan3 through the CAN line, connect the USB line of the ValueCan3 to the industrial computer 2, and connect the load signal output terminal of the BCM1 to the corresponding analog load in the load box 4 through a hard line. Connect, at this time the flashing pre-installation of BCM1 is completed;

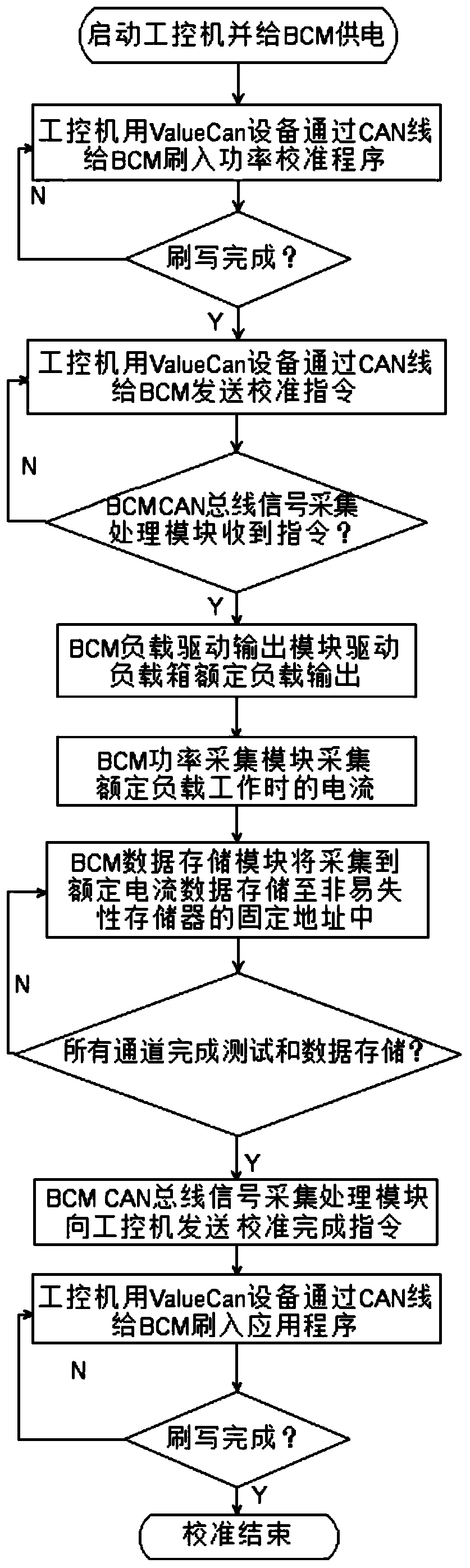

[0037] Step 2: flash into the calibration program, the industrial computer 2 uses ValueCan3 to flash into the power calibration program for BCM1 through the CAN line;

[0038] Step 3: Rated power calibration, acquisition, storage, industrial computer 2 uses ValueCan3 to send calibration instructions to BCM1 through the CAN line, until the CAN bus signal acquisition and processing module of BCM1 receives the calibration instruction, BCM1 load drive after BCM1 receives the calibrat...

Embodiment 2

[0042] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0043] The rated power of the simulated load in the load box 4 is the same as the rated power of the corresponding equipment on the vehicle; in the third step, after the BCM1 receives the calibration instruction, the load drive output module of the BCM1 drives the load box 4 to output at the rated load, referring to BCM1 drives the output of each load interface in sequence, and each output is kept for 3 seconds. After the output is stable, read the feedback voltage value corresponding to the analog load and calculate the rated current, and store the rated current in the corresponding address space as Benchmark parameters for fault diagnosis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com