Beating type walnut hull breaking and kernel taking device

A shell-breaking device and striking technology, which is applied in the field of mechanical equipment, can solve problems such as the nucleolus being easily corroded, difficult to control, and walnut kernel pollution, and achieve the effects of shortening labor time, reducing processing costs, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

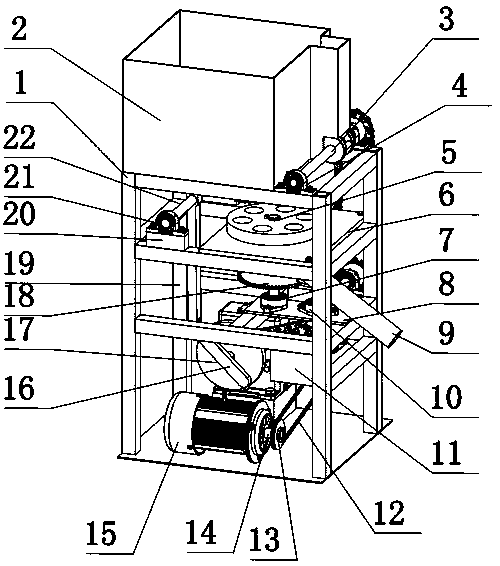

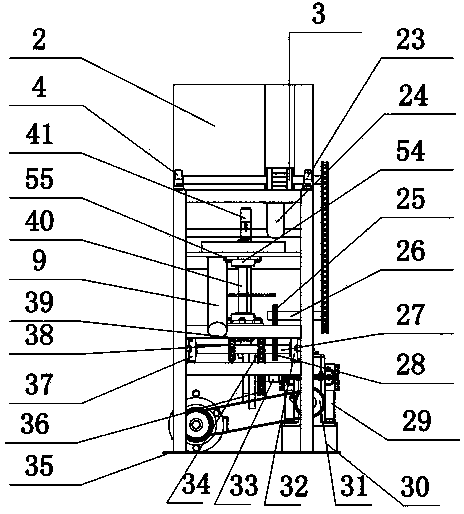

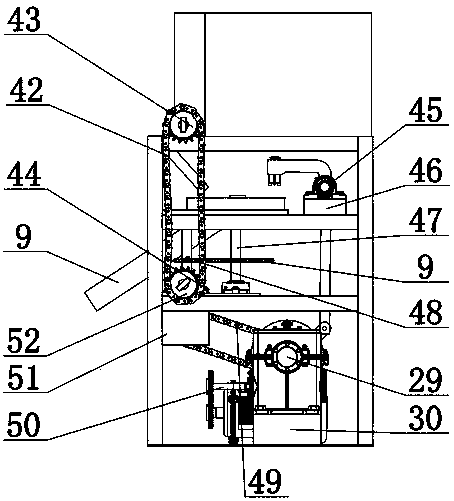

[0032] As shown in the figure, the equipment as a whole includes a frame 1, a transmission system, a feeding device, and a shell breaking device.

[0033] Said motor is installed on the bottom plate 35 of the whole machine, and the frame 1 is mainly used for fixedly connecting and assembling the structure of each part of the machine. , Fixed plate I11, disc bottom plate 6.

[0034] Said transmission system is to provide power source by being connected with reducer 29 by motor 15, 15 rotating speeds of motor 680r / mm, reducer gear 36 and the rotating shaft I gear 34 on the rotating shaft I27 are connected by chain 49; The driving helical gear 38 meshes with the driven helical gear 39 on the end face of the rotating shaft III40, and its transmission ratio is 1:1; the small gear 48 on the rotating shaft III40 meshes with the large gear 18 on the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com