Chip removal cleaning device for exhaust pipe production

A technology for cleaning devices and exhaust pipes, which is applied in the direction of cleaning methods using tools, removing smoke and dust, using liquid separators, etc. Easy to clean and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

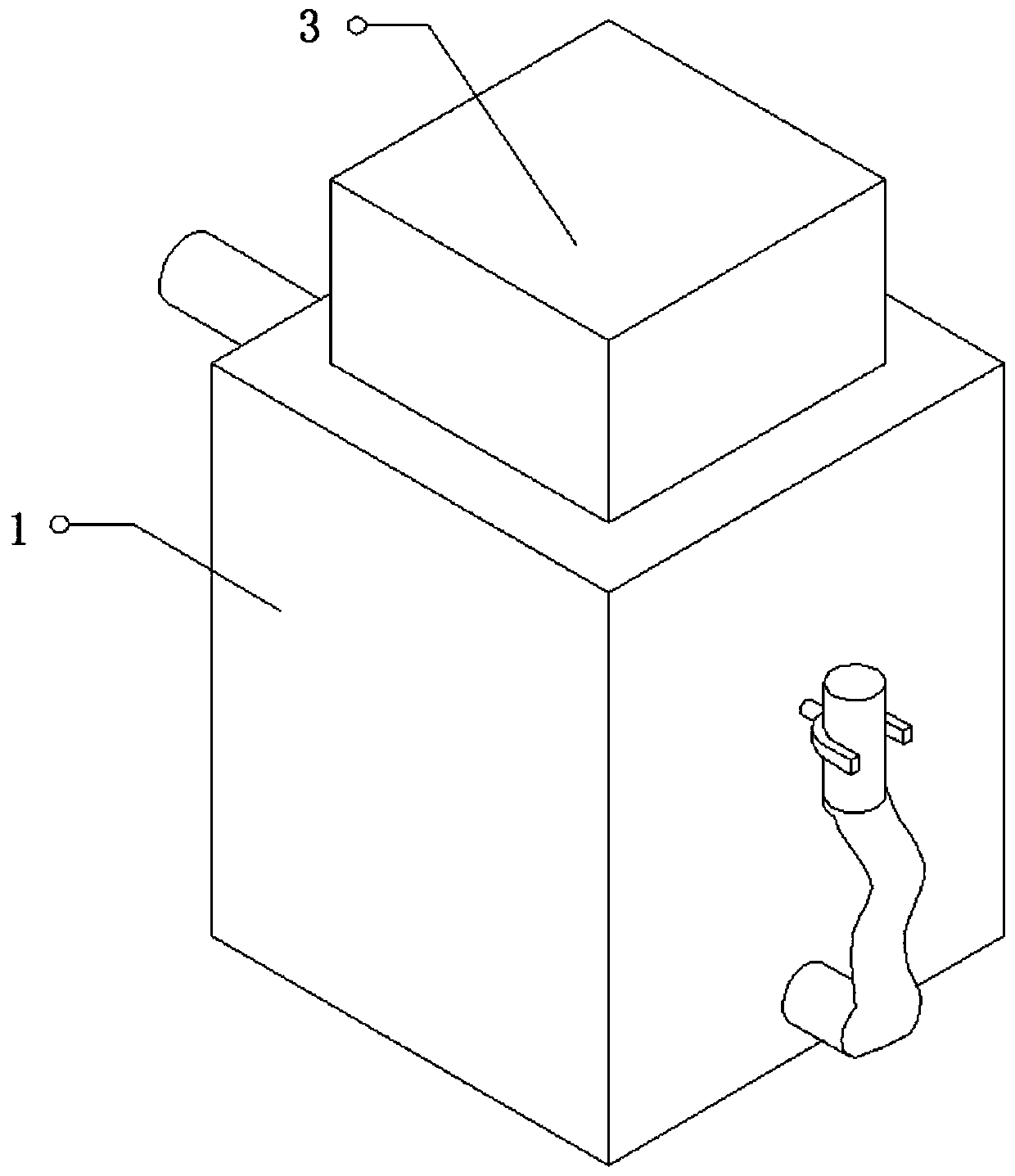

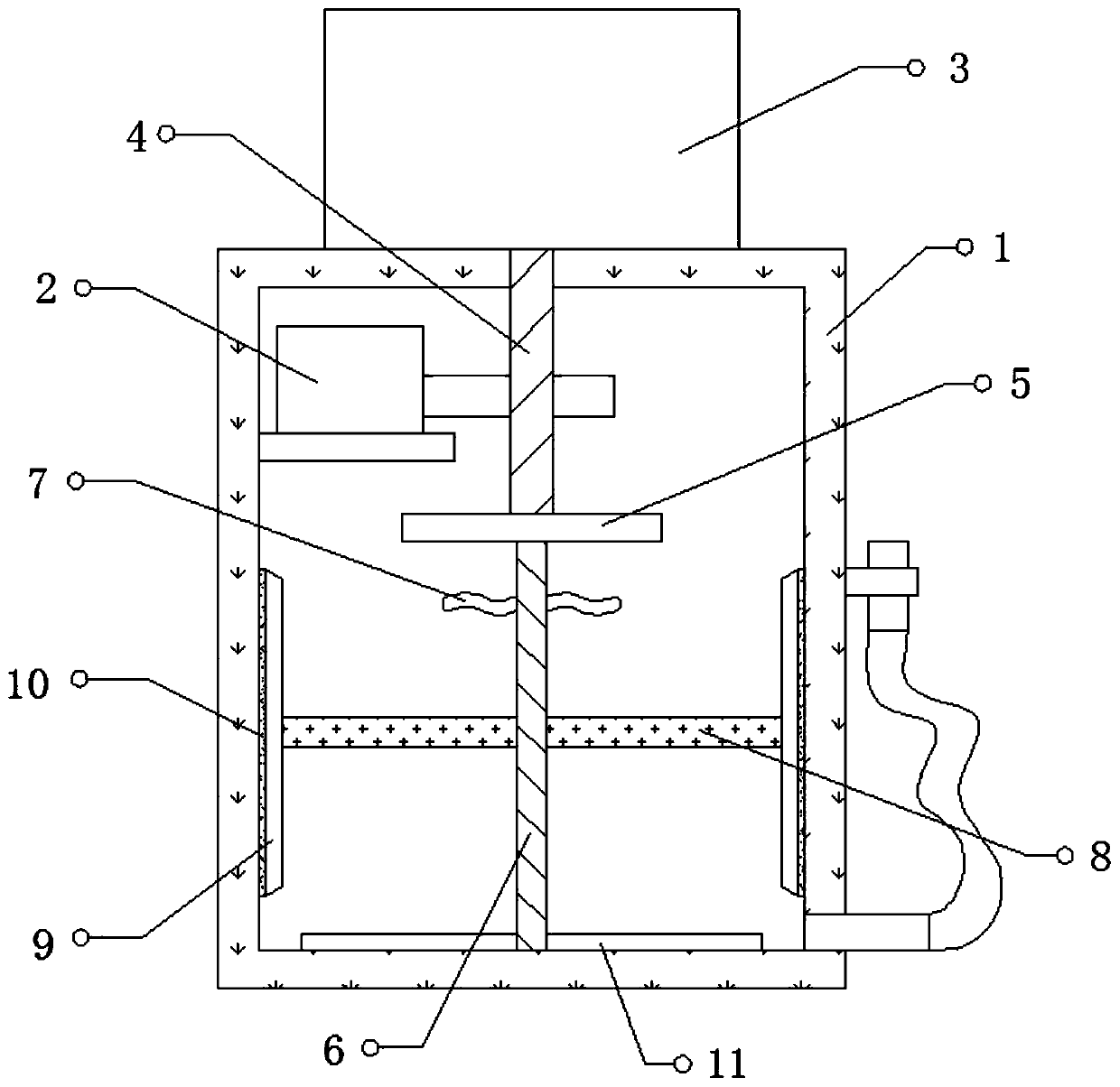

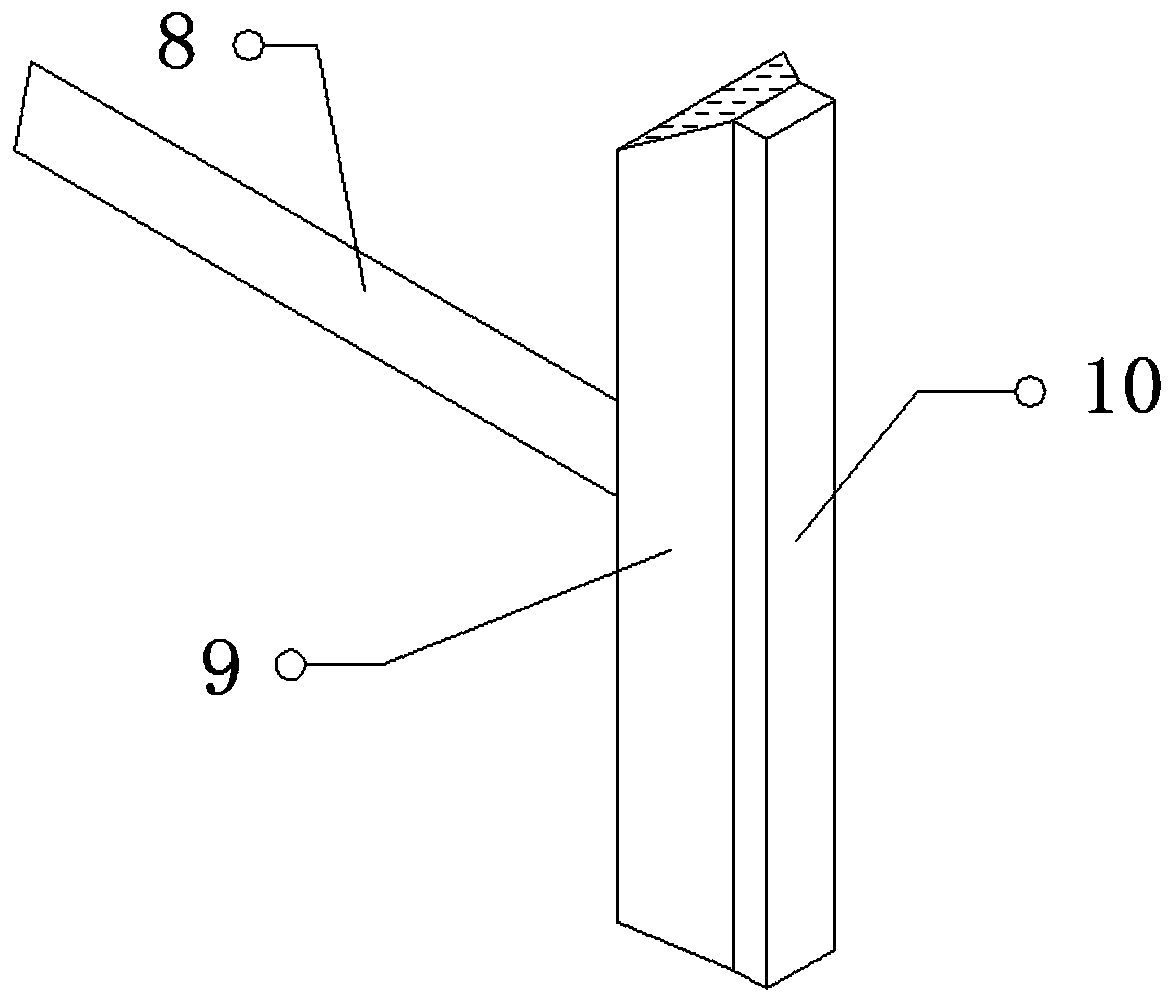

[0025] refer to Figure 1-4 , a chip cleaning device for exhaust pipe production, including a cleaning box 1, a dust suction pump 2 is fixed on one side of the top inner wall of the cleaning box 1, and the air inlet and outlet ends of the dust suction pump 2 are respectively connected to the air inlet The air duct and the air outlet duct, the air inlet duct extends to the outside, the air outlet duct is arranged inside the cleaning box 1, the bottom of the side of the cleaning box 1 is provided with a drain pipe, the top of the cleaning box 1 is provided with a water tank 3, and the water tank The bottom of 3 is connected with connecting pipe 4, and the bottom of connecting pipe 4 is fixed with sprinkler plate 5, and connecting rod 6 is connected with rotation between the outer wall of sprinkler plate 5 bottom and the bottom inner wall of cleaning box 1, and the top of connecting rod 6 circumference outer walls is fixed. There are blades 7 distributed in an annular array, and ...

Embodiment 2

[0028] refer to figure 1 with Figure 3-5 , a chip removal and cleaning device for exhaust pipe production, further, a storage box 13 is slidably connected to the side of the top inner wall of the cleaning box 1 away from the dust suction pump 2, and the bottom of the storage box 13 is provided with an opening, and the storage box 13 The top inner wall is fixed with a magnetic plate 14, which absorbs the iron debris entering the inside of the cleaning box 1 by using the magnetic plate 14, thereby improving the classification effect. The top of the inner wall of the cleaning box 1 near the magnetic plate 14 is fixed with an obliquely arranged baffle. The plate 15 uses the dust suction pump 2 to enter the debris into the cleaning box 1 and collides with the baffle plate 15, and through the rebound effect, it is ensured that the magnetic plate 14 fully absorbs the iron debris.

[0029] Working principle: In the spare part of the device, connect all the above-mentioned driving pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com