Immersion ship special for immersed tube tunnel, and using method of immersion ship

An immersed tube tunnel and sinking technology, applied in the directions of pipe laying ships, water conservancy projects, artificial islands, etc., can solve the problems of low pipe joint sinking and docking efficiency, large water level drop, narrow river channels, etc., to improve equipment utilization, The effect of improved docking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

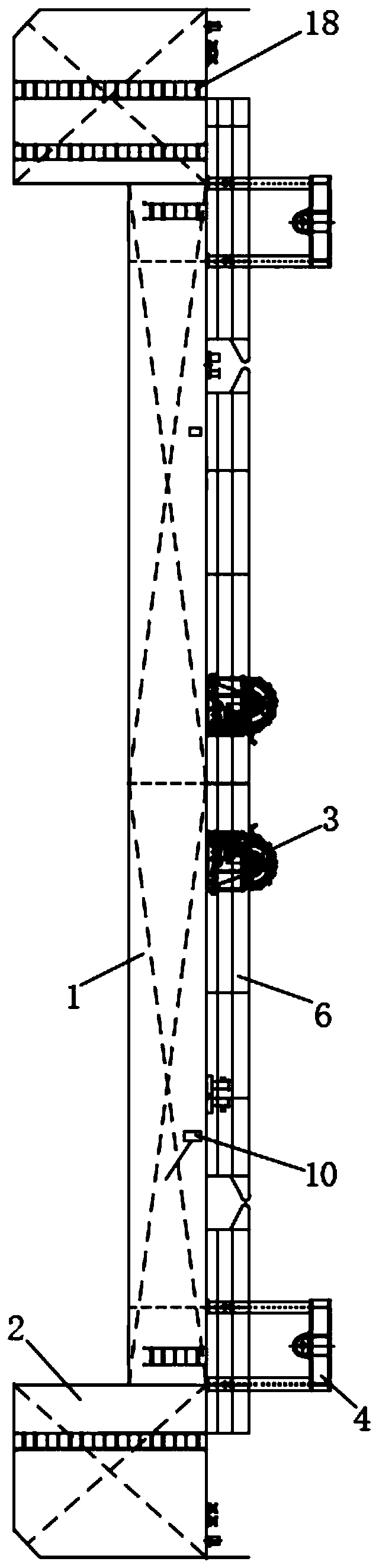

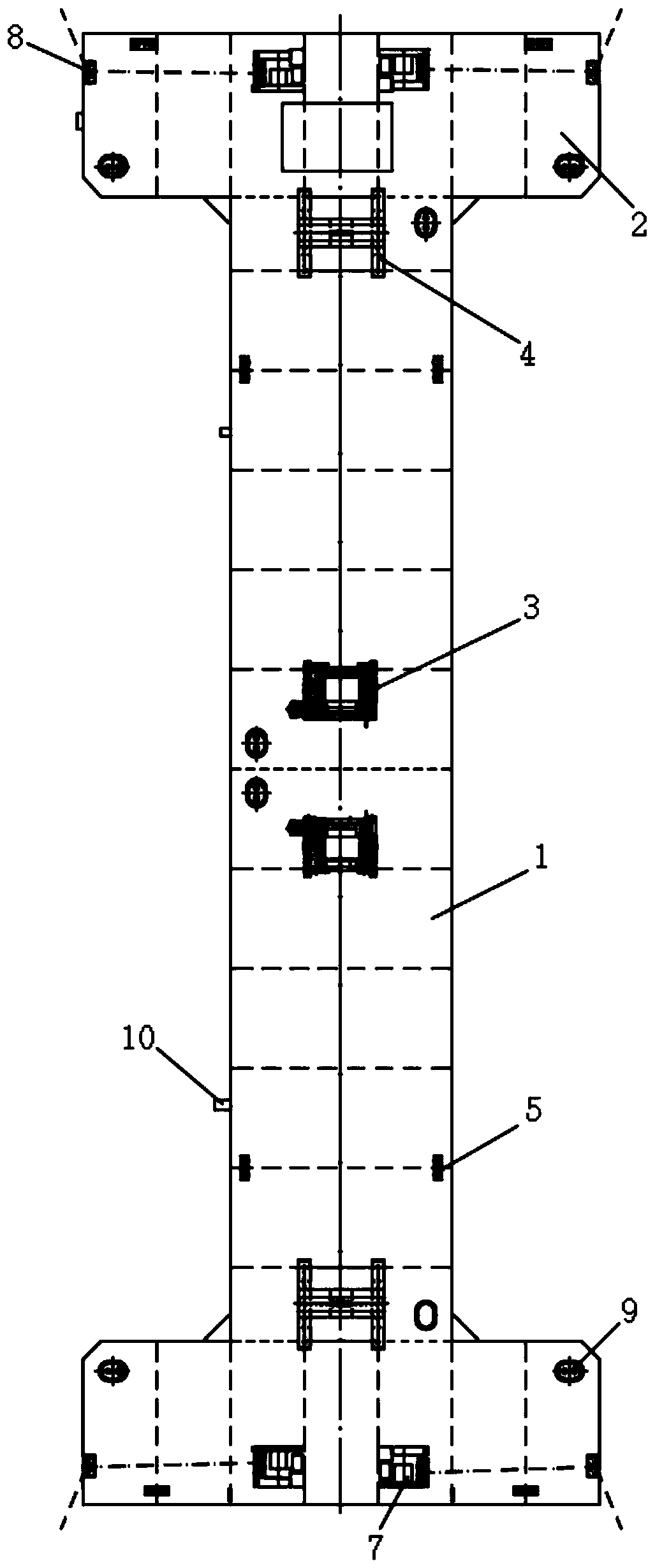

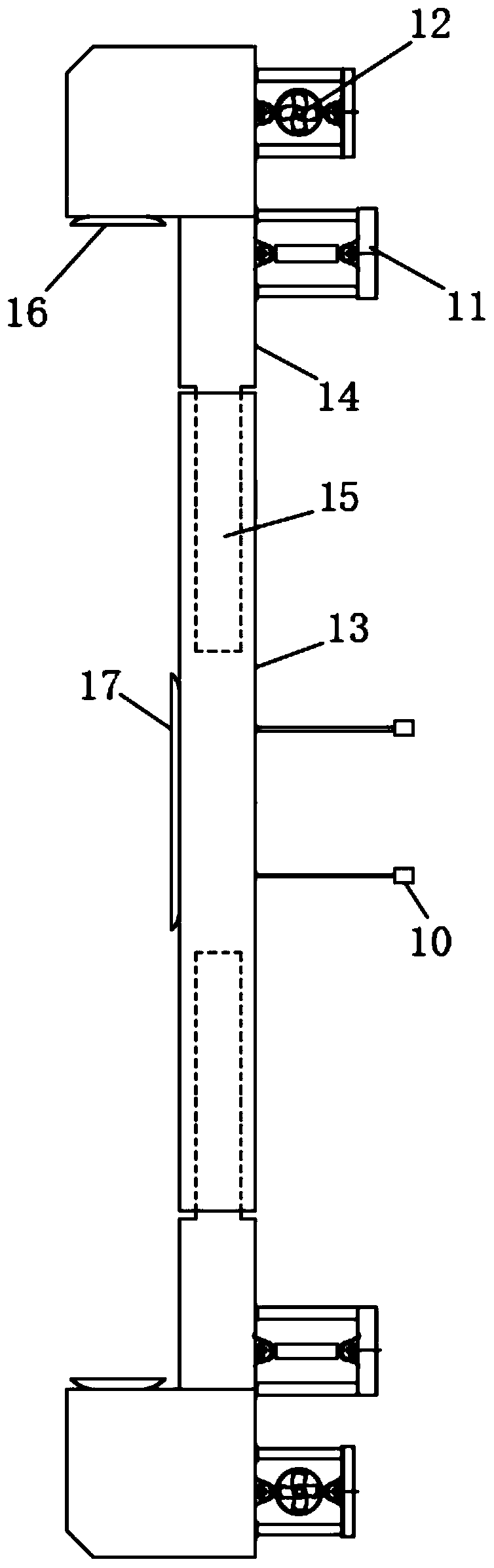

[0032] refer to Figure 1-4 , a sinking ship dedicated to immersed tube tunnels, including a gantry box girder 1, the gantry box girder 1 includes a fixed section 13 and two telescopic sections 14, the fixed section 13 is fixed, and the expansion and contraction of the telescopic end can be driven by a telescopic hydraulic cylinder. In this way, the length of the hull can be adjusted stably and quickly, so that it is convenient to limit the pipe sections of different widths, which is convenient and quick. Both ends of 1 are fixedly connected with the hull buoyancy tank 2, and the hull buoyancy tank 2 can drive the gantry box girder 1 and the sinking pipe section for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com