Shipborne repairing equipment for large-size river and lake polluted water repairing

A water quality, large-scale technology, applied in water/sewage treatment equipment, polluted waterway/lake/pond/river treatment, special-purpose ships, etc. Problems, to achieve the effect of easy repair and avoid death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

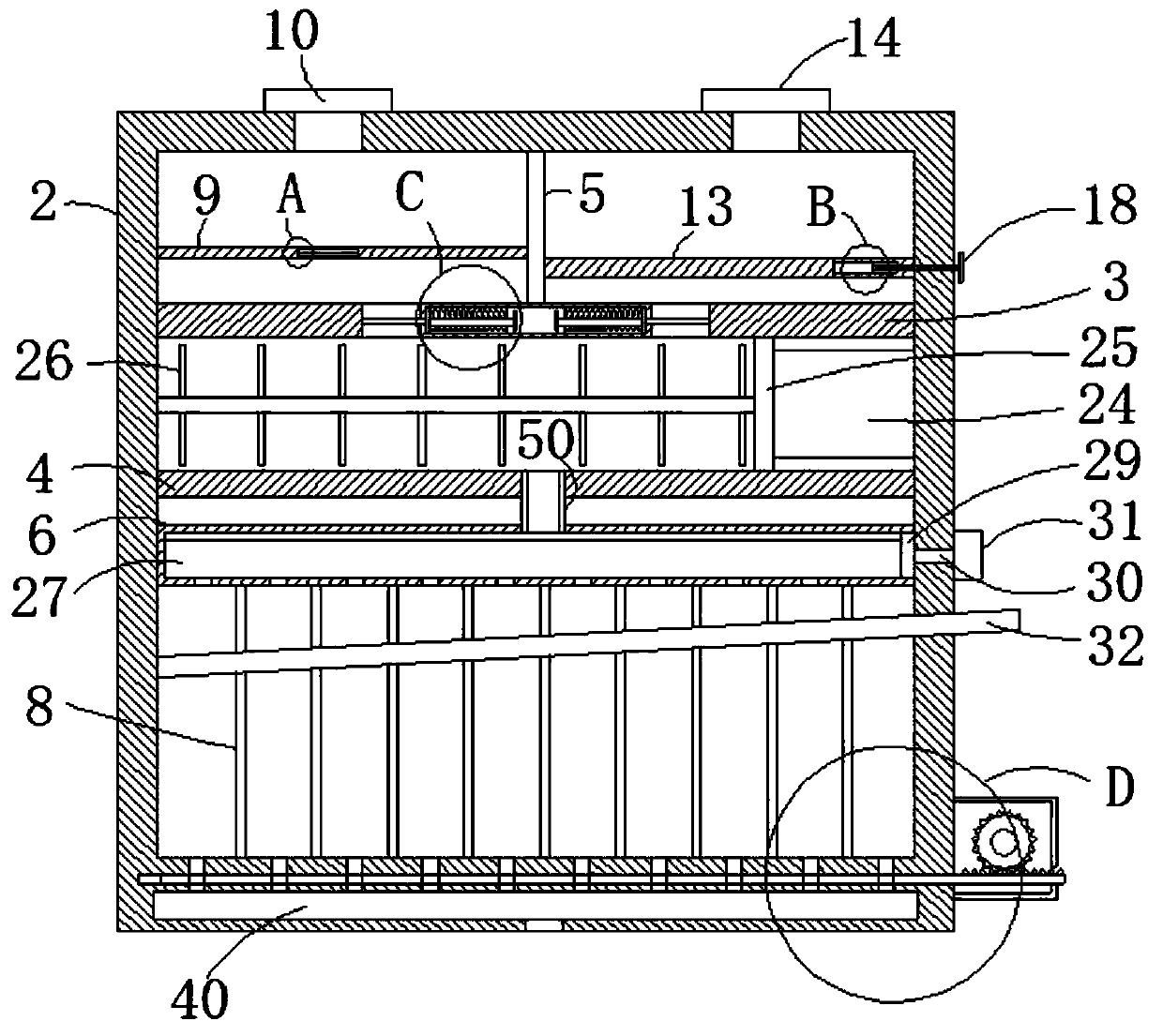

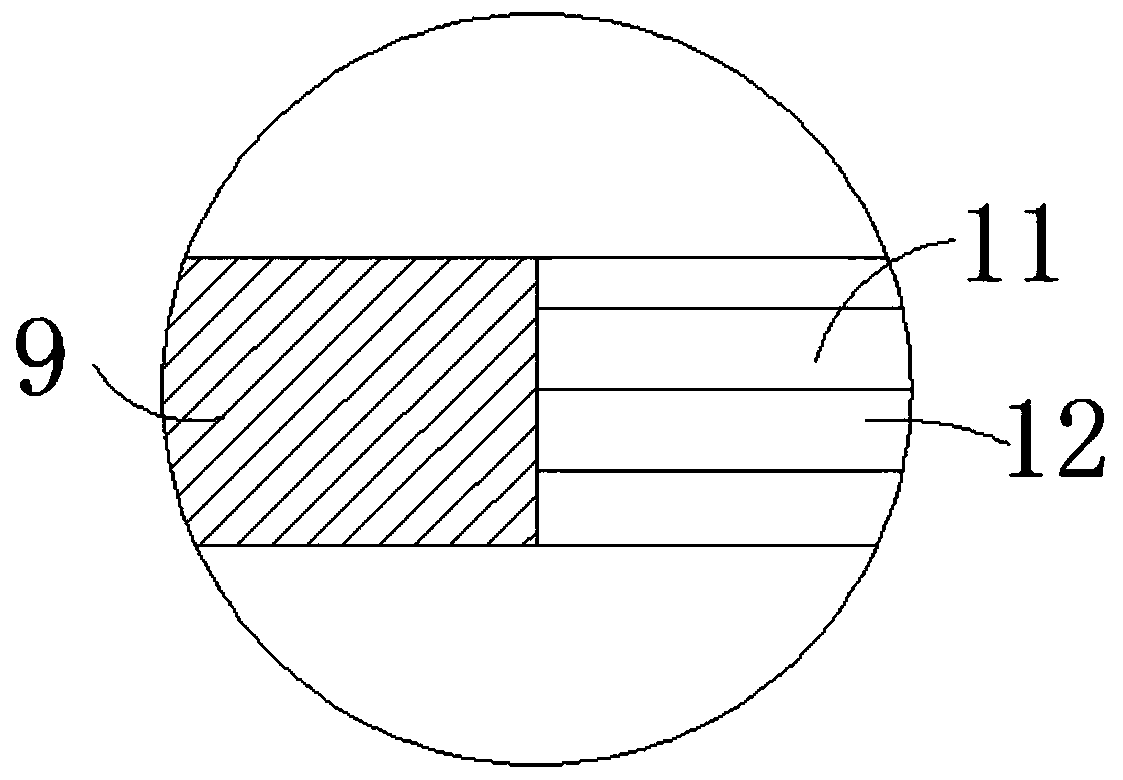

[0025] Such as Figure 1-8 As shown in the figure, a ship-mounted repairing equipment used for repairing the polluted water quality of large rivers and lakes includes a hull 1, the upper end of the hull 1 is fixedly connected with a treatment box 2, and the inner side wall of the treatment box 2 is fixedly connected with a first transverse plate 3 and a second horizontal plate 3. Two horizontal plates 4, the inside of the processing box 2 is divided into a storage room, a batching room and a breeding room from top to bottom by the first horizontal plate 3 and the second horizontal plate 4, and the side wall of the material storage room is fixedly connected with a vertical plate 5. The material storage room is divided into a first storage mechanism for containing nutrient solution and a second storage mechanism for containing clean water by the vertical plate 5. On the side wall of the first horizontal plate 3, there are corresponding The positions are all provided with a mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com