Lengthened hopper capable of being bent

A funnel and bending technology, which is applied in the field of bendable lengthened funnels, can solve the problems of tortuous channels and holes for cement pouring that cannot be vertically connected up and down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in combination with specific embodiments.

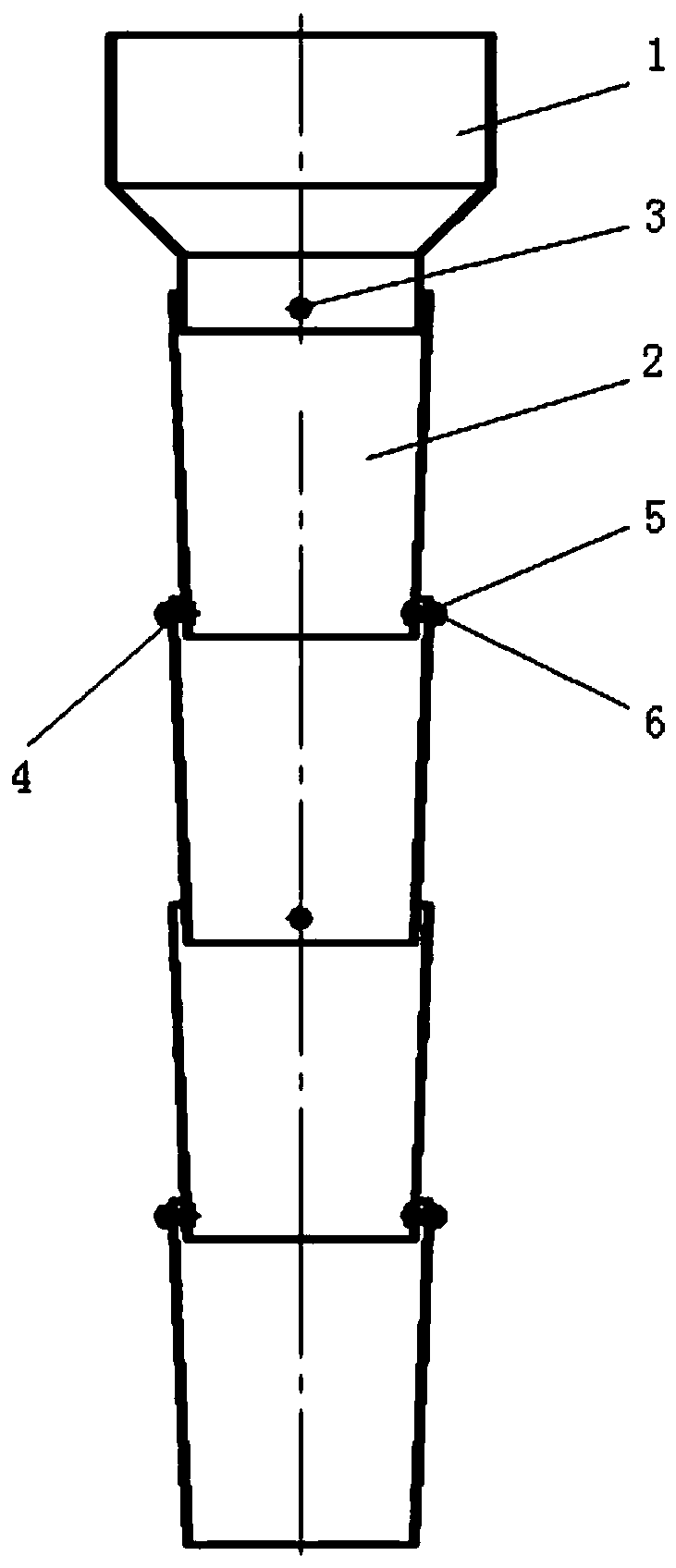

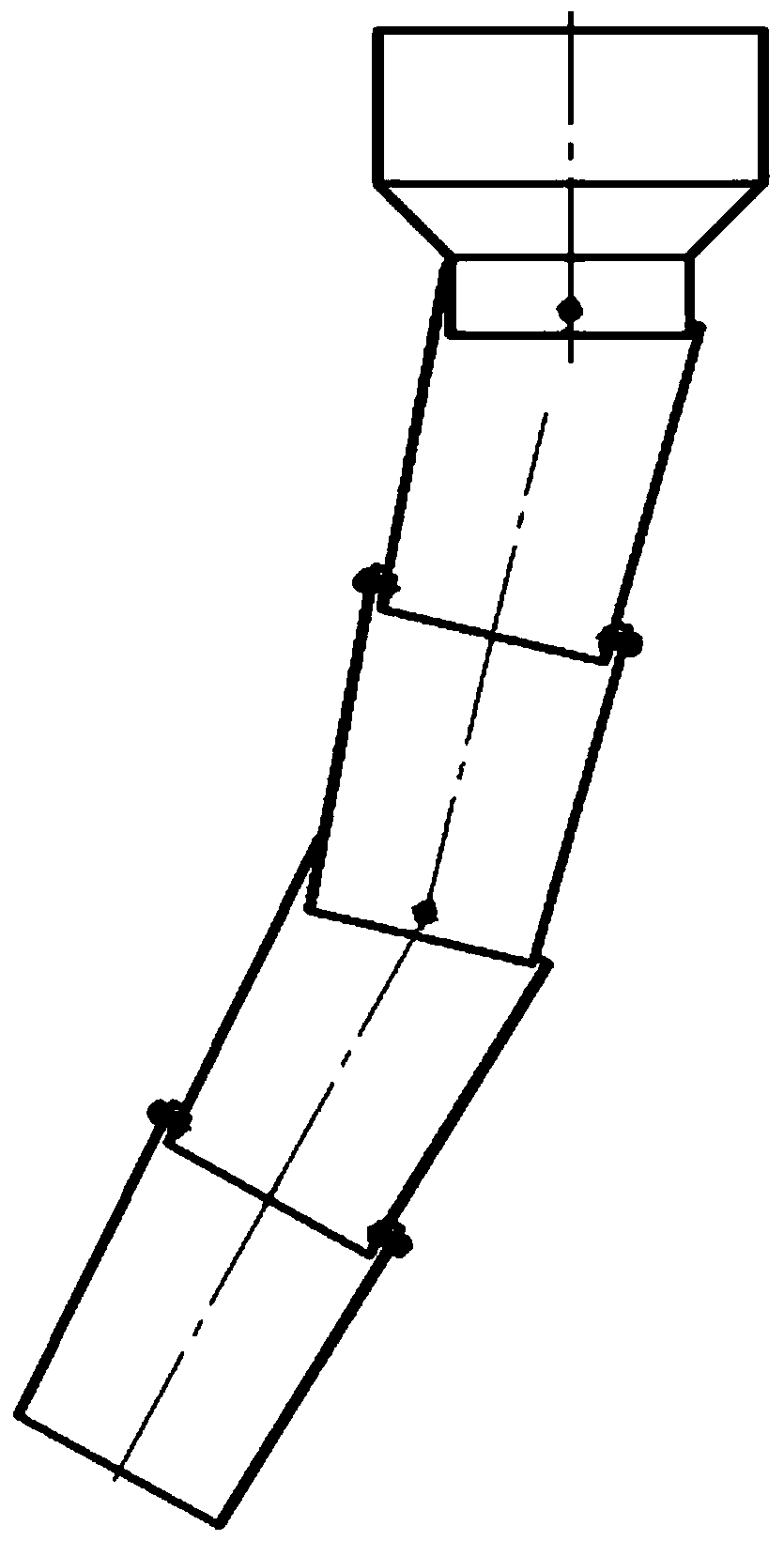

[0009] The bendable lengthening funnel of the present invention is as figure 1 with figure 2 As shown, it includes a feed hopper 1 and a number of bent pipe bodies 2. The first connecting holes 3 are provided on both sides of the lower end of the feed hopper 1. The bent pipe body 2 is a tapered barrel with a large upper part and a smaller lower part. Both sides of the upper and lower ends of 2 are provided with second connecting holes 4, and the center lines of the connecting holes at the upper and lower ends of the bent pipe body are perpendicular to each other. The first connecting hole 3 and the second connecting hole 4 are connected by screws 5, and the screws 5 A lock nut 6 is provided on the top, and the screw 5 is locked by the lock nut 6, so that the gap between the inner and outer jackets of the joint is even, and the second connection hole 4 of each bent pipe ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap