An integrated structure and construction method of assembly and pouring combination of subway underground excavation station

A technology that integrates structures and construction methods, applied in shaft equipment, earthwork drilling, underground chambers, etc., can solve the problems of large impact on the surrounding environment, poor construction environment, and many dismantling and replacement procedures, and achieve less temporary engineering and industrialization High, meet the technical requirements of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

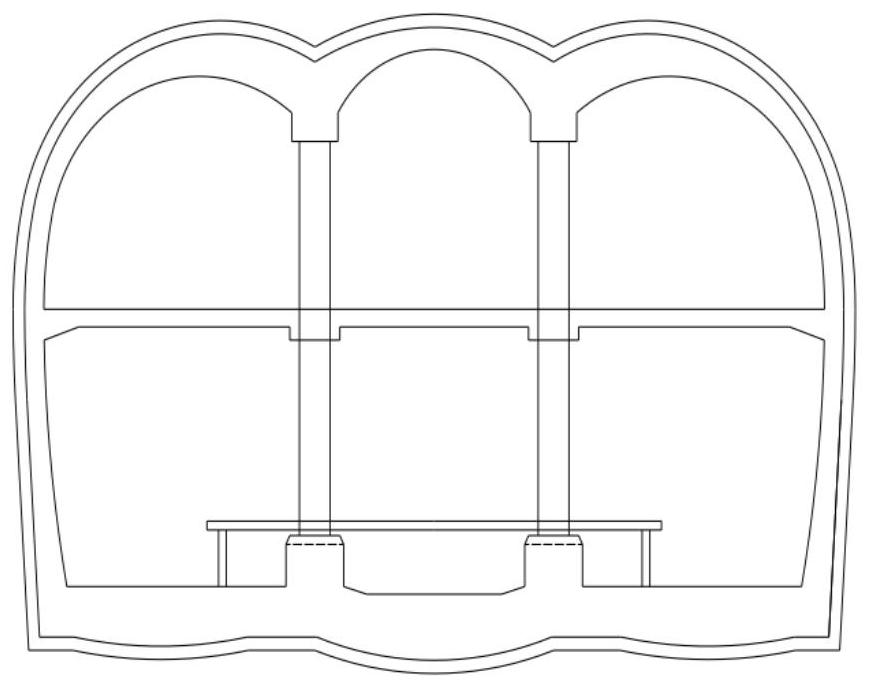

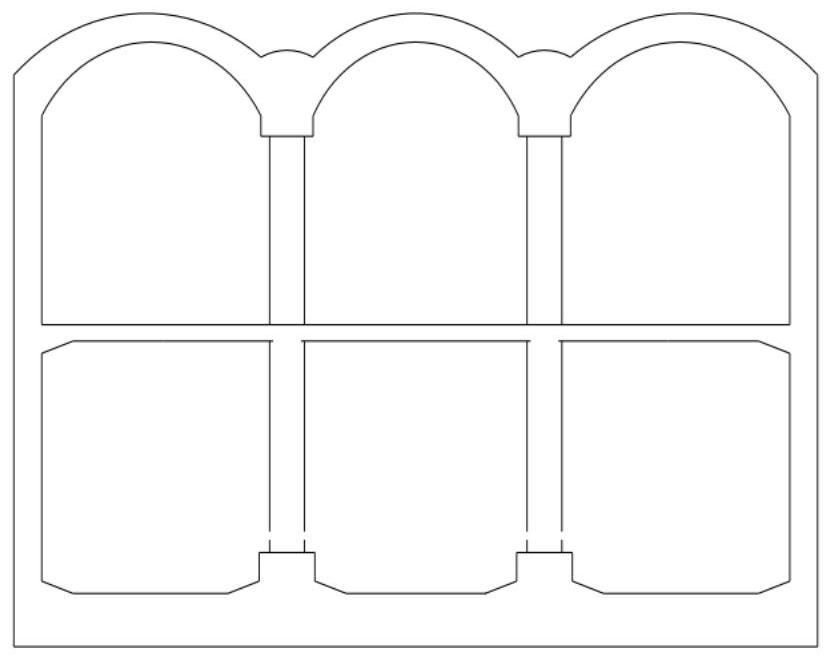

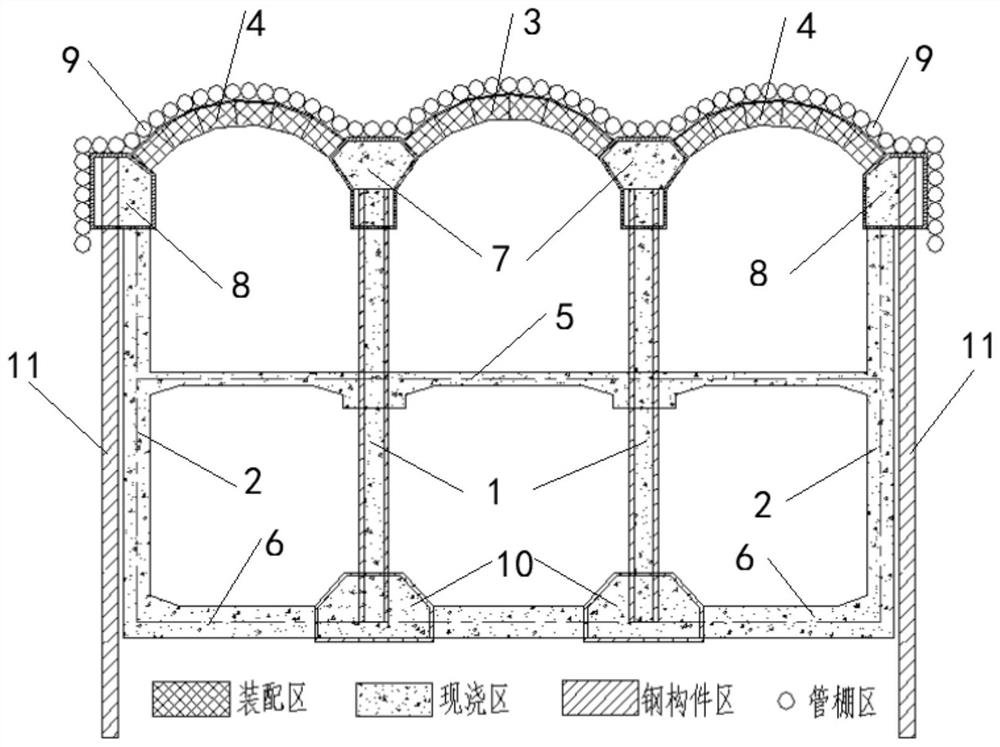

Image

Examples

Embodiment Construction

[0059] The present invention will be described in detail below with reference to the drawings and in combination with specific embodiments. Each example is provided by way of explanation of the invention, not limitation of the invention. In fact, those skilled in the art will recognize that modifications and variations can be made in the present invention without departing from the scope or spirit of the invention. It is intended that the present invention encompass such modifications and variations as come within the scope of the appended claims and their equivalents.

[0060] It is known from the simulated excavation that the maximum displacement and maximum stress change of the surrounding rock during the entire excavation process occurred in the two construction steps of the upper soil mass in the excavation and the superstructure construction after a large amount of excavation of the internal soil mass. The displacement of the soil in the upper part of the middle hole ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com