Low-entropy collaborative optimization method for workshop layout scheduling

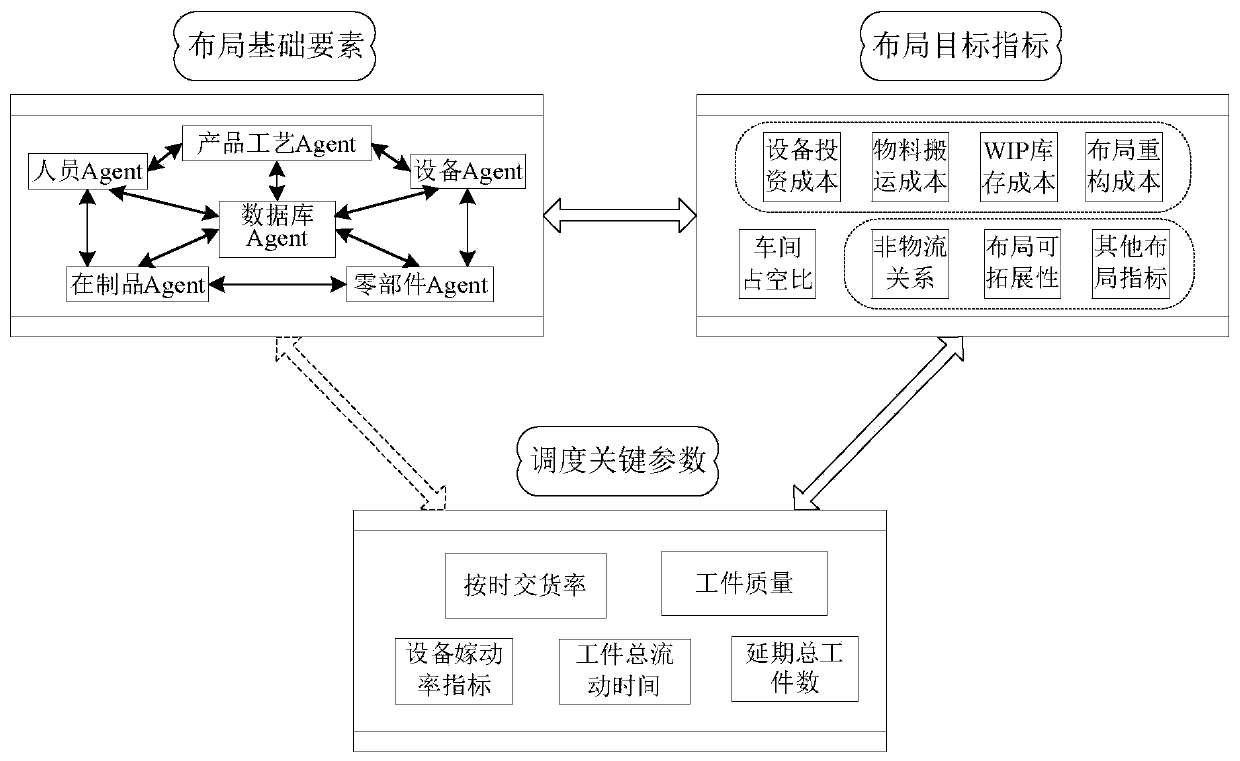

A collaborative optimization and layout technology, applied in the field of integrated optimization of workshop layout scheduling, can solve problems such as ineffective integration and affecting scheduling results, and achieve the effects of reducing dwell time, increasing processing speed, and reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] Problem description and related data: A machining workshop needs to produce 8 kinds of workpieces, each workpiece contains multiple different processing procedures, and consists of 12 machine tools, including 4 lathes M1 / M2 / M3 / M4 and 3 milling machines M5 / M6 / M7, 3 planers M8 / M9 / M10, 2 grinders M11 / M12, the layout of the processing workshop is as follows Figure 8 As shown, the processing time and processing quality of each process on different machines are shown in Tables 4 and 5, and Table 6 shows the adjustment time of equipment processing adjacent workpieces and the processing cost per unit time of the machine.

[0092] Comprehensively considering the machining range, operating range and loading and unloading area of the machine tool, set the distance parameters between each machine tool as follows: d d = 1m; L m = 5m; d r = 3m; b m = 2m.

[0093] Table 4 Machine processing time (s)

[0094]

[0095] Table 5 Machining Quality

[0096]

[0097] Table 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com