A kind of multilayer ceramic capacitor and its preparation method

A technology of multilayer ceramics and capacitors, which is applied in the manufacture of capacitors, laminated capacitors, capacitors, etc., can solve the problems of multilayer ceramic capacitors’ reliability deterioration, short-circuit failure rate increase, and deterioration, so as to prevent short-circuit failure rate from increasing and reliable Deterioration of performance, prevention of increase in short-circuit defect rate, and prevention of reliability deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

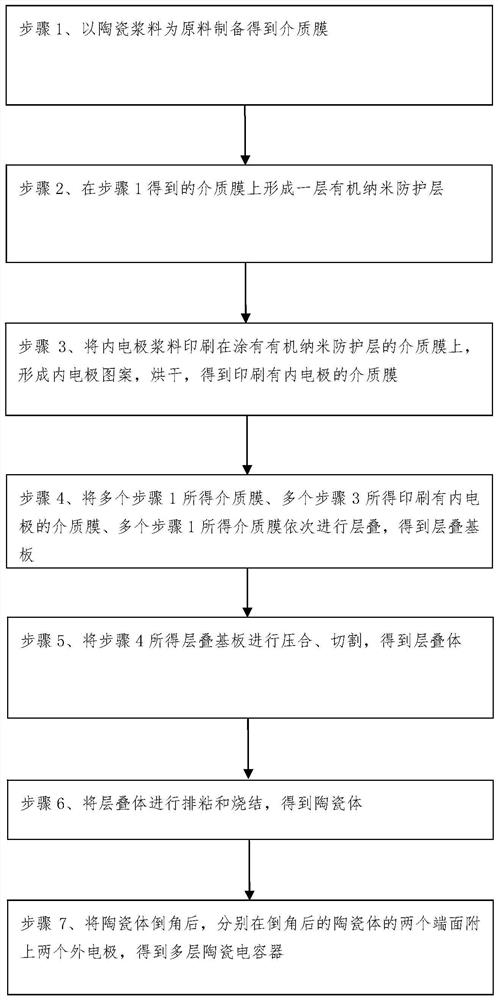

[0040] An embodiment of the multilayer ceramic capacitor of the present invention, combined with figure 1 , the multilayer ceramic capacitor described in this embodiment is prepared by the following method:

[0041] Step 1: Mix ceramic powder, organic binder and organic solvent evenly to obtain a ceramic slurry, and then use the ceramic slurry as a raw material to prepare a dielectric film.

[0042] The ceramic powder, the organic binder and the organic solvent are uniformly mixed by a sand mill ball milling method, and the ball milling time can be 5h-10h.

[0043] The mass ratio of ceramic powder, organic binder and organic solvent is 10:3-5:6-9.

[0044] The main component of the ceramic powder is barium titanate; the organic binder is polyvinyl butyral; the organic solvent is a mixed solvent of toluene and ethanol with a mass ratio of 1-1.5:1.

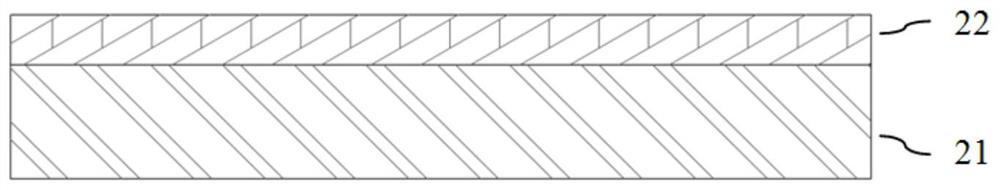

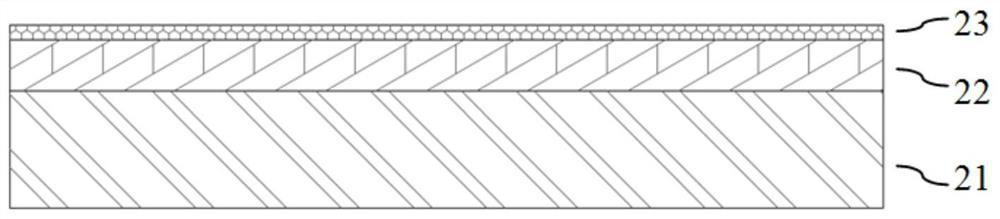

[0045] Such as figure 2 As shown, the prepared ceramic slurry is cast on a PET carrier tape 21 as a carrier and dried to obtai...

Embodiment 2

[0071] An embodiment of the multilayer ceramic capacitor of the present invention, the multilayer ceramic capacitor described in this embodiment is prepared by the following method:

[0072] The difference from Example 1 is that the organic nano protective agent consists of 3-20wt% fluorine-containing acrylate, 79-96wt% diluent and 0.3-1.5wt% initiator. The diluent is one or more of ethyl acetate, isobutanol, propylene glycol methyl ether, n-butyl acetate, and methyl isobutyl ketone; the initiator is tertiary amine derivatives, benzoin and its derivatives, acetophenone One of derivatives and aromatic ketones;

[0073] The liquid organic nano protective agent is sprayed by high-pressure gas, sprayed on the surface of the dielectric film in the form of nanoscale gaseous spray, and then cured under ultraviolet light to form an organic nano protective layer attached to the surface of the dielectric film.

[0074] The application sets the experimental group 1-8 and the control gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com