Farmland sprinkler irrigation system with automatic fertilization function

A farmland, automatic technology, applied in the field of farmland sprinkler irrigation system, can solve the problems of high work pressure, low work pressure, and many micro-spray belts, etc., and achieve the effect of reducing the average investment per mu, improving the service life and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

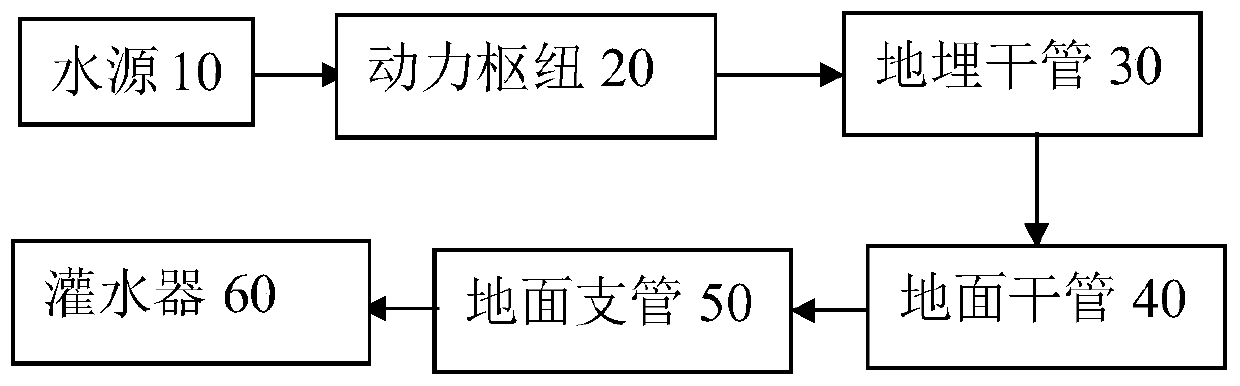

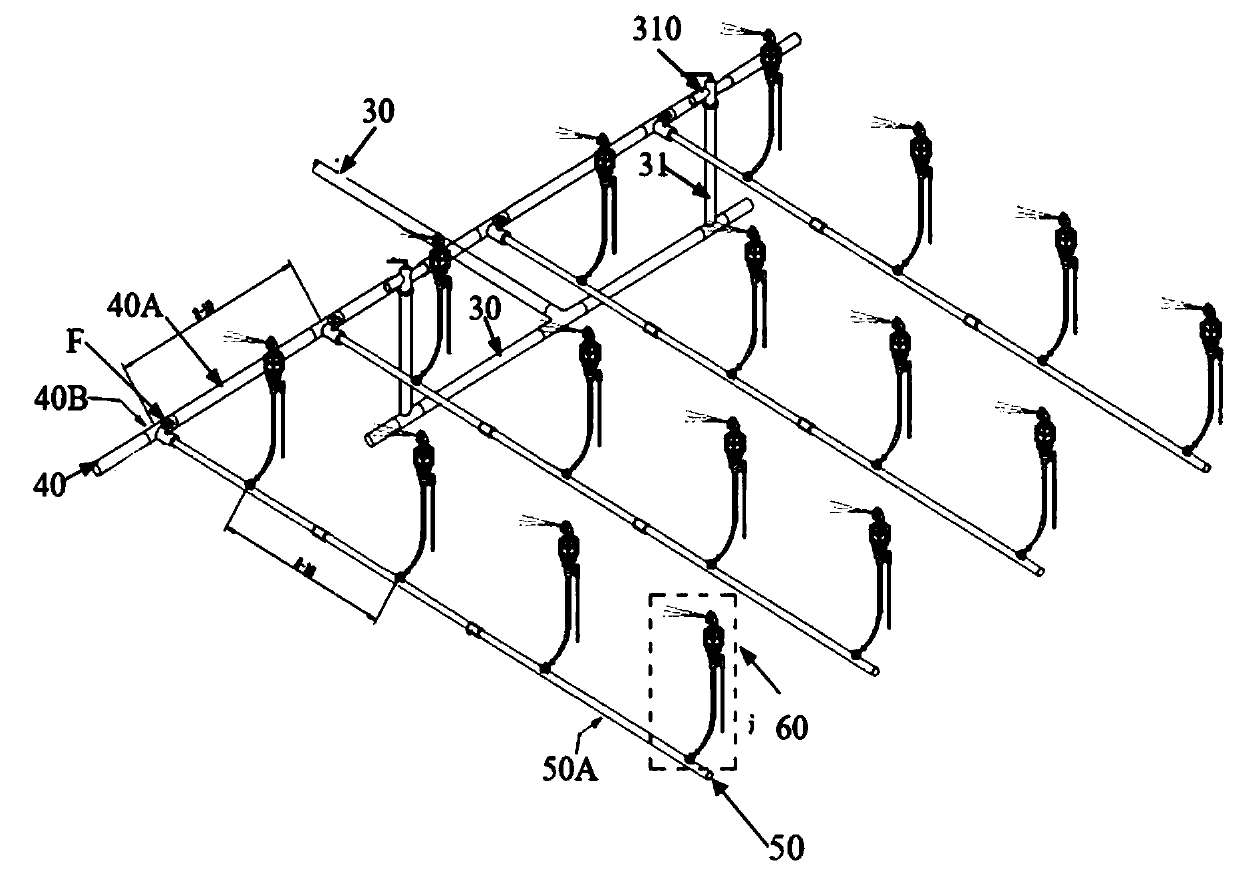

[0038] combine Figure 1-4 Shown is a sprinkler irrigation system 100 according to a preferred embodiment of the present invention, including a water source 10 for providing irrigation water, a power hub 20 , an underground main pipe 30 , a ground main pipe 40 , a ground branch pipe 50 and an emitter 60 .

[0039] The water source 10 is well water, surface water, or reservoir water storage.

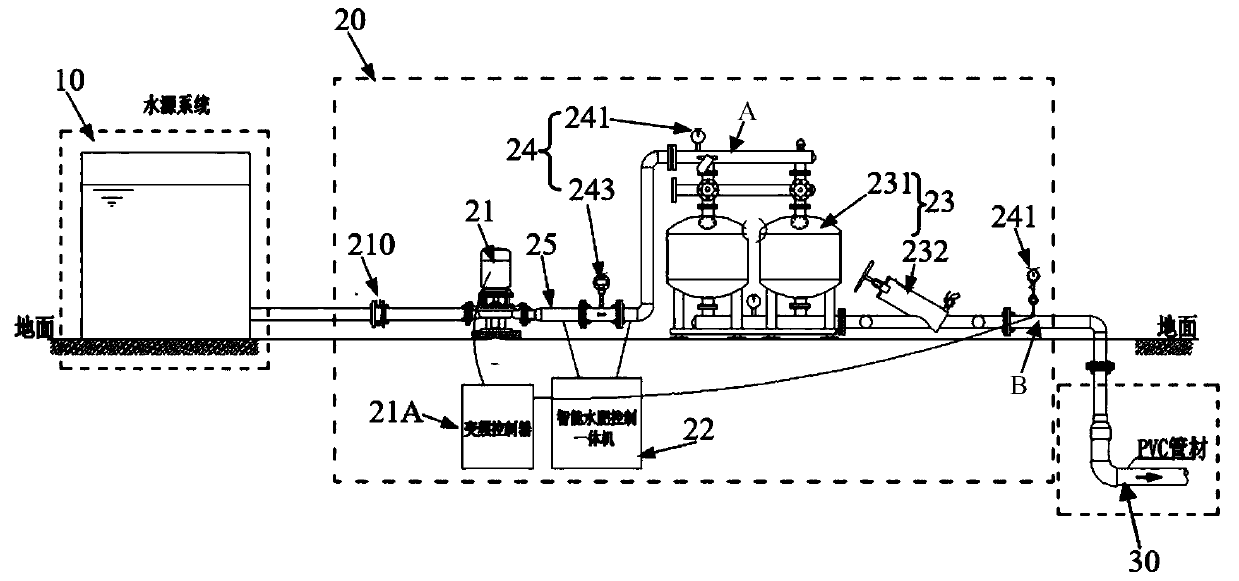

[0040] combine figure 2 As shown, the power hub 20 includes a valve system 210 , a water pump 21 , an intelligent water and fertilizer control integrated machine 22 , a filter device 23 , a metering device 24 and pipe fittings 25 . The pipe fitting 25 connects the aforementioned parts.

[0041] The water source 10 is connected to the valve system 210 through the pipe fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com