Circular self-desilting type gravity desilting filter tank

A technology of self-discharging and filtering tanks, applied in the field of grit chambers, can solve the problems affecting the recharging efficiency, maintenance cost and service life of recharging facilities, and achieve the benefits of sedimentation, uniform and stable distribution of water flow velocity, and favorable sedimentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] For the convenience of description, the direction of the water flow is the back, and the direction of the incoming water is the front.

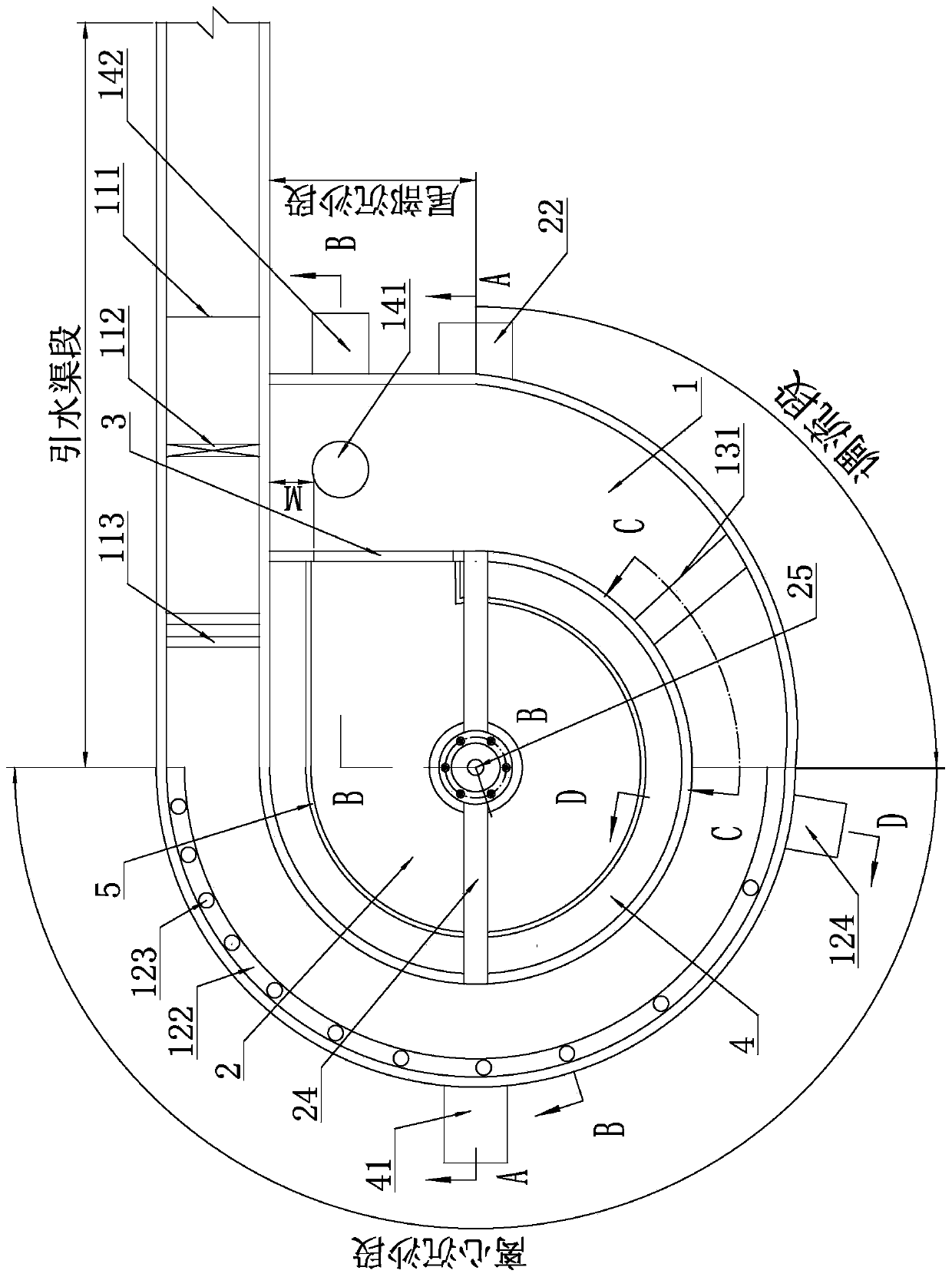

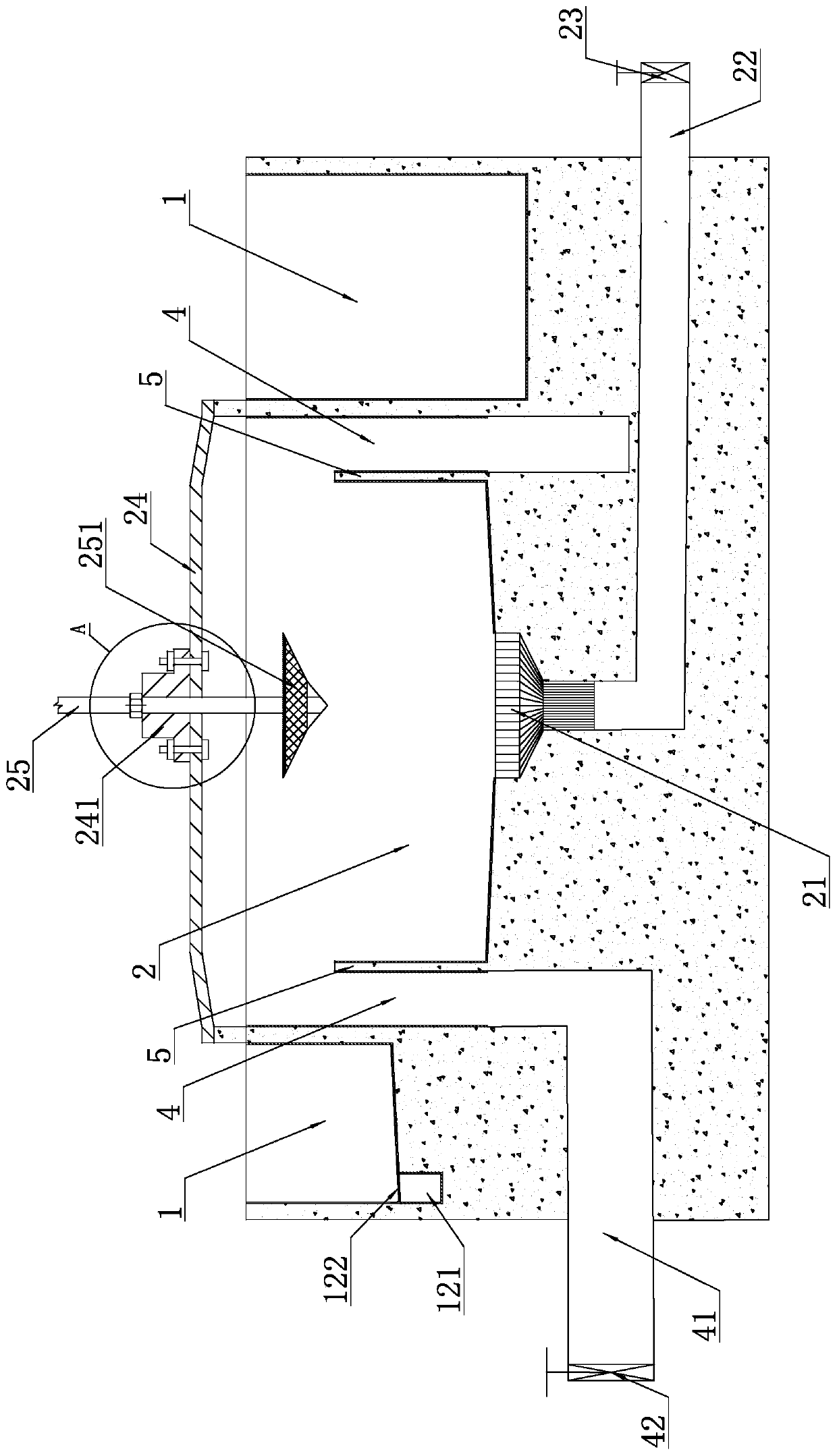

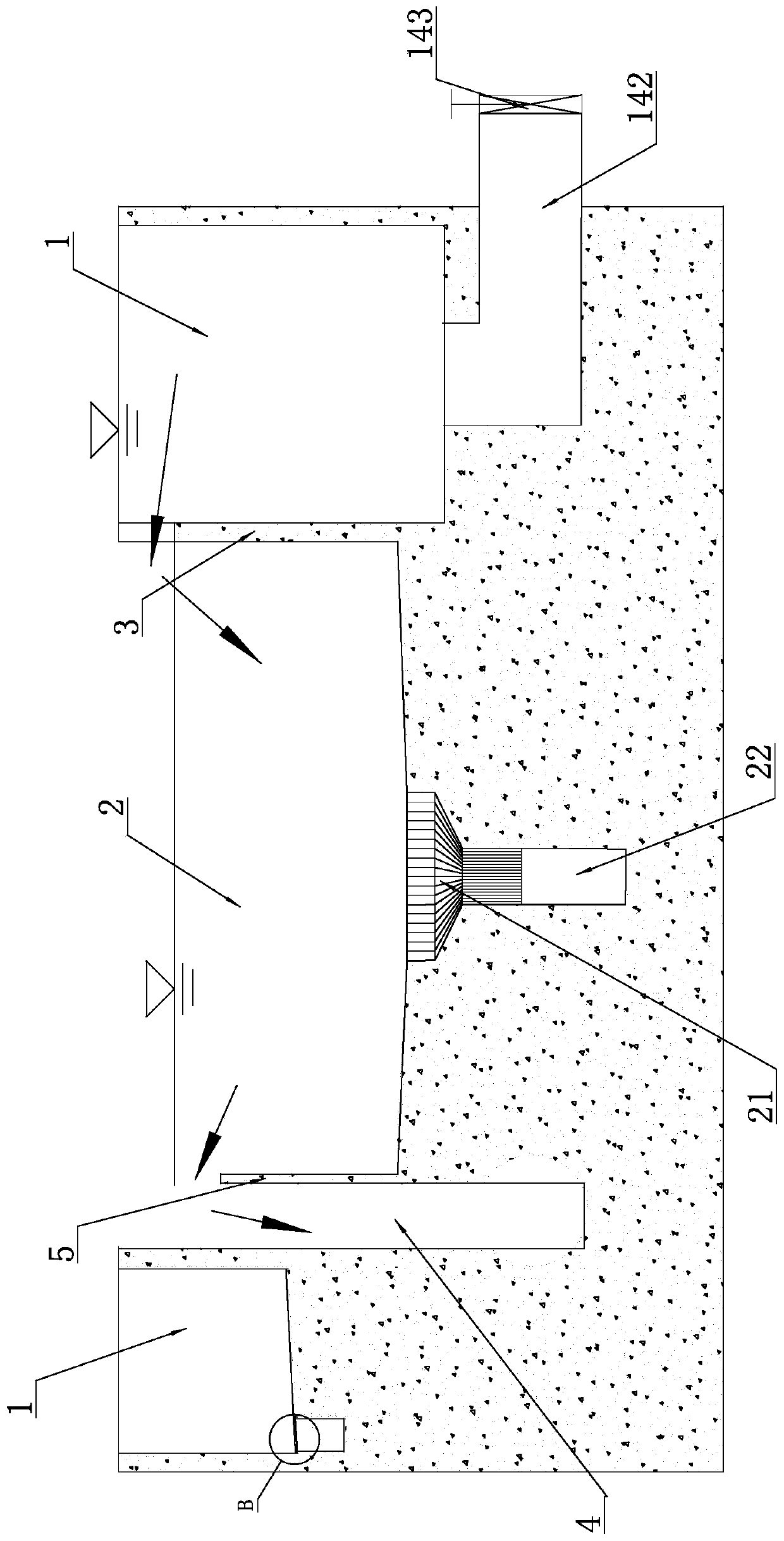

[0038] Such as figure 1 As shown, a circular self-draining gravity grit filter tank includes an outer grit tank 1, and the outer grit tank 1 is successively divided into a diversion channel section and a centrifugal grit section along the direction of water flow. , the diversion section and the tail sedimentation section, wherein the diversion channel section and the tail sedimentation section are linear structures, the centrifugal sedimentation section and the flow regulation section are arc-shaped structures, and the tail sedimentation The tail end of the section extends to the side wall of the aqueduct section, and the aqueduct section, the centrifugal sedimentation section, the flow regulation section and the tail sedimentation section together form a closed inner layer sedimentation tank 2 .

[0039] A first overflow weir 3 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com