Rolling high speed blender

A technology of wall breaker and crusher, applied in grain processing and other directions, can solve the problems of low processing efficiency, insufficient food processing, and small effective area, and achieve the effect of improving processing efficiency, fine food taste, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

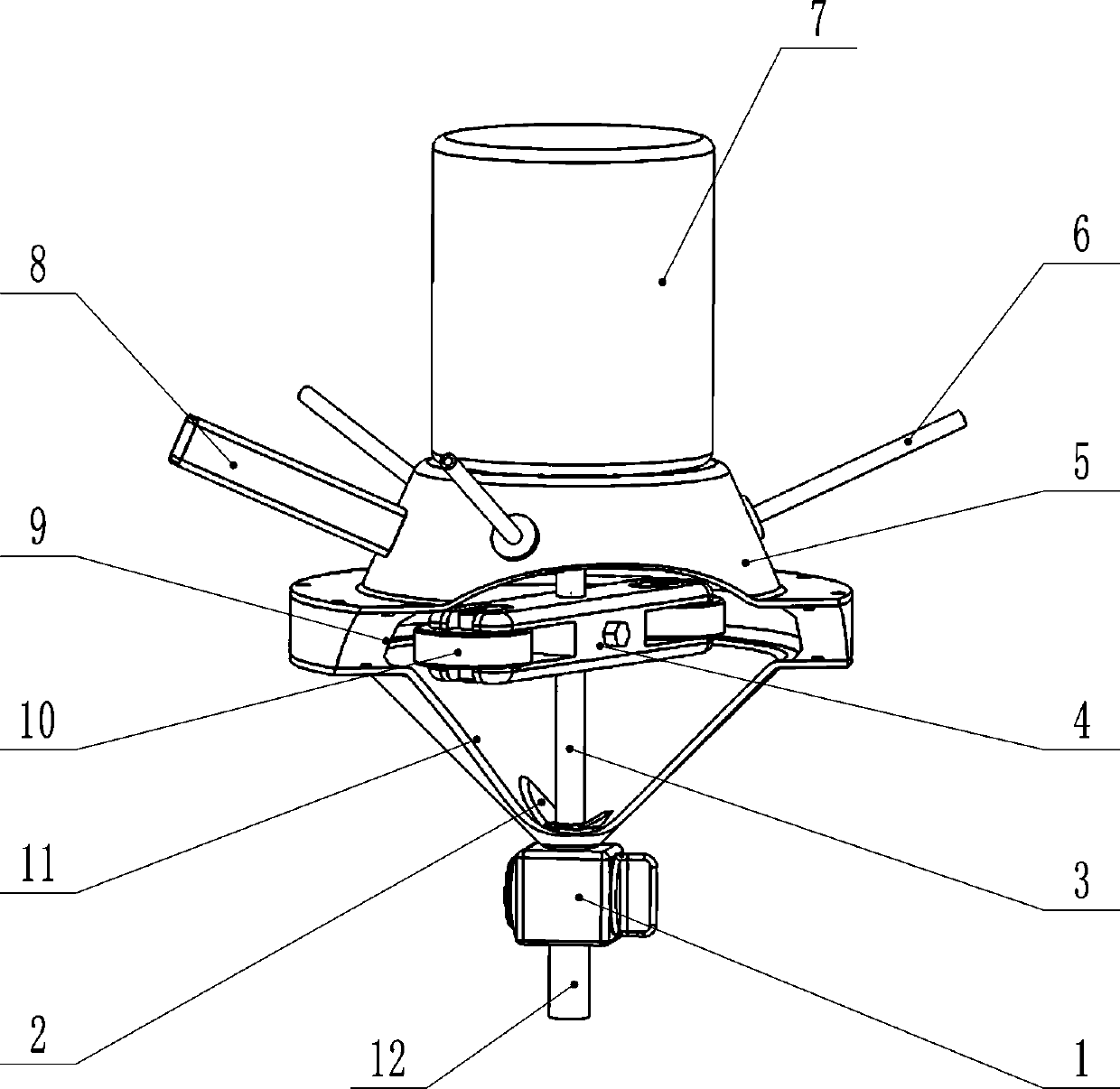

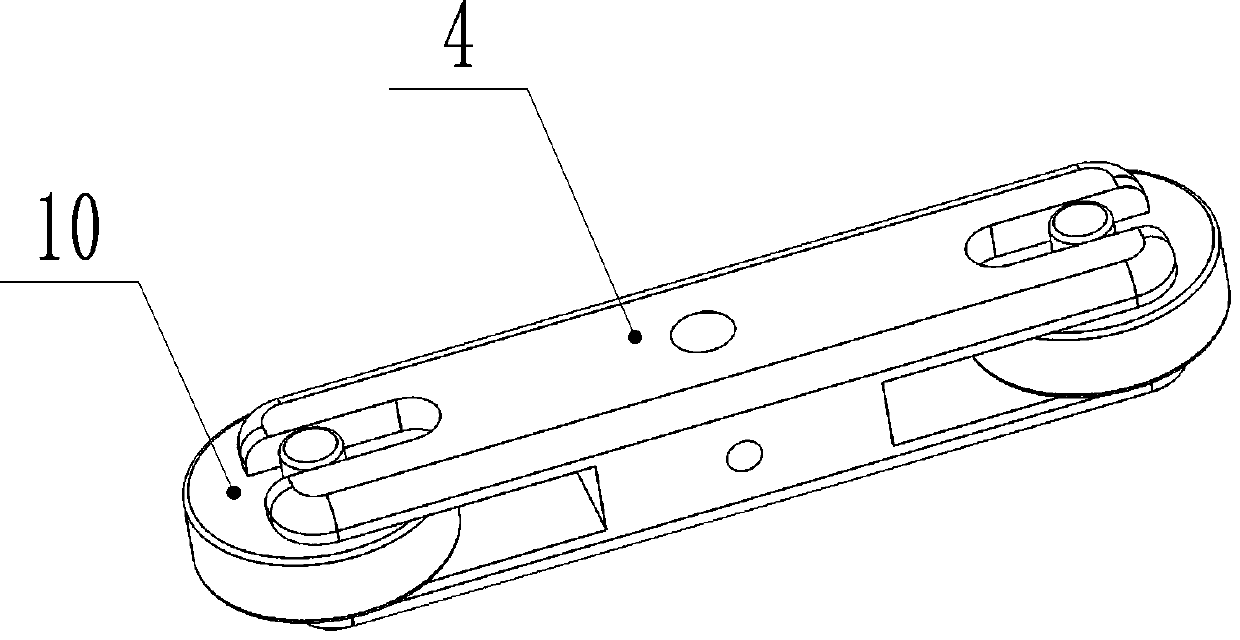

[0029] Such as figure 1 and figure 2 As shown, a rolling crushing machine includes a motor 7 and a main body of the breaking machine. The main body of the breaking machine is provided with a crushing cavity, and the crushing cavity includes a conical cutting cavity 11 at the lower part and a horizontal cutting cavity at the middle part. Ring groove type grinding chamber 9, the output shaft 3 of the motor 7 is longitudinally arranged in the crushing chamber, the output shaft 3 in the chopping chamber 11 is partially equipped with a crushing blade 2, and the output shaft in the grinding chamber 9 The shaft 3 part is equipped with a roller centrifugal frame 4, and two symmetrical grinding wheels 10 are installed on the outer end of the roller centrifugal frame 4. When the output shaft of the motor 7 rotates at a high speed, the grinding wheel 10 is under centrifugal force. Walk in the grinding chamber 9 of the horizontal ring groove type; the main body of the wall breaker is pr...

Embodiment 2

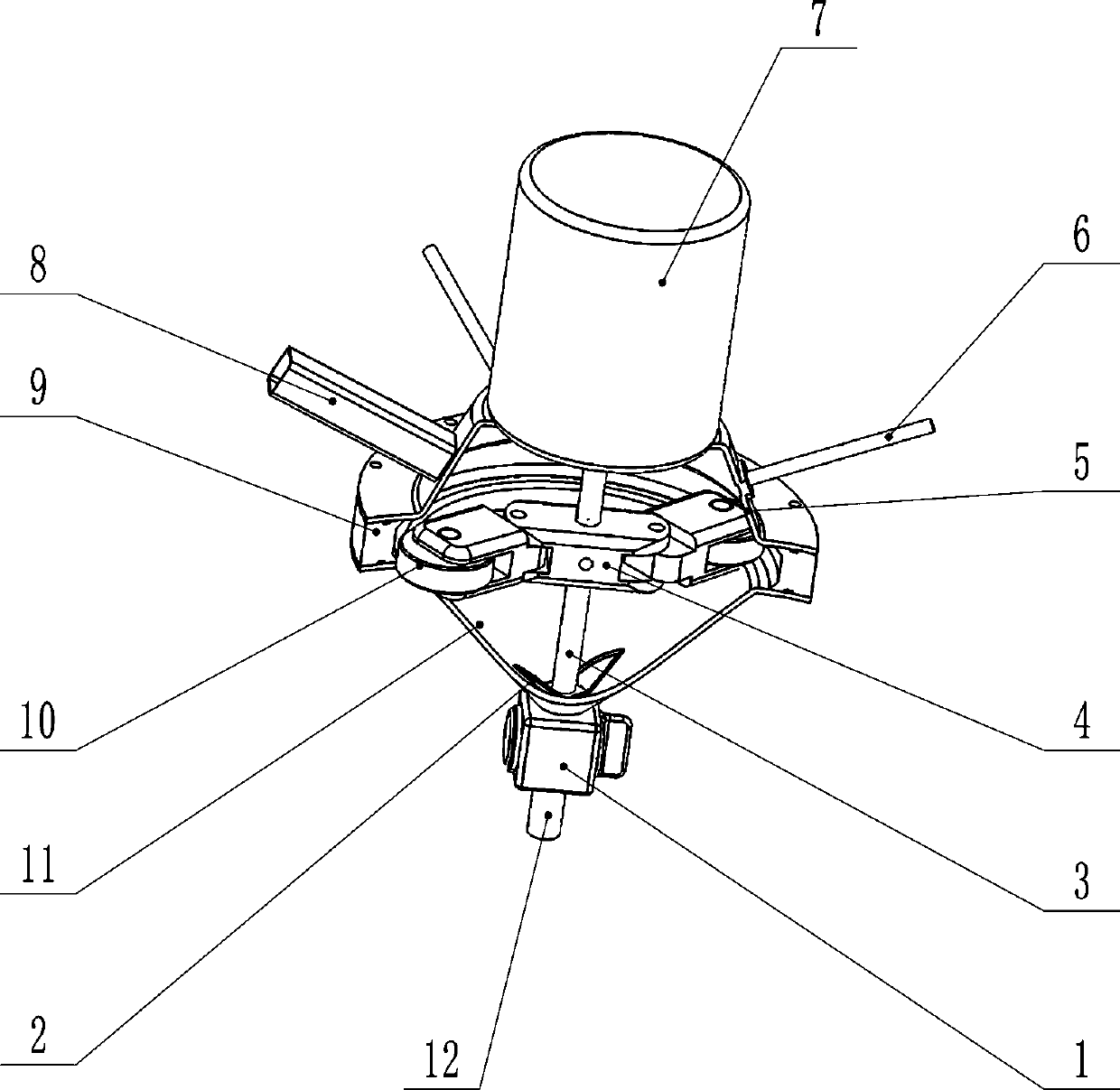

[0038] Such as image 3 and Figure 4 As shown, the difference from Embodiment 1 is that the roller centrifuge rack includes a base 4 and a roller arm 13 hinged on the base, the roller 10 is mounted on the roller arm 13, and the base 4 fixed on the output shaft 3.

[0039] This structure form is another kind of centrifugal structure, and the roller is less restricted.

Embodiment 3

[0041] Such as Figure 5-Figure 8 As shown, the difference from Embodiment 1 and Embodiment 2 is that the roller 10 is a gear, and the groove wall of the grinding chamber is a tooth groove 14 matched with the roller. Under the tooth structure, the rolling direction is more diverse and complicated, so as to avoid some hard and smooth particles from collapsing and flying in the process of rolling in a single direction, which has never been processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com