Detection device for automobile brake caliper support

A brake caliper and detection device technology, applied in mechanical gap measurement, sorting and other directions, can solve problems such as low detection efficiency and poor detection accuracy, and achieve the effects of ensuring stability, improving detection accuracy, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

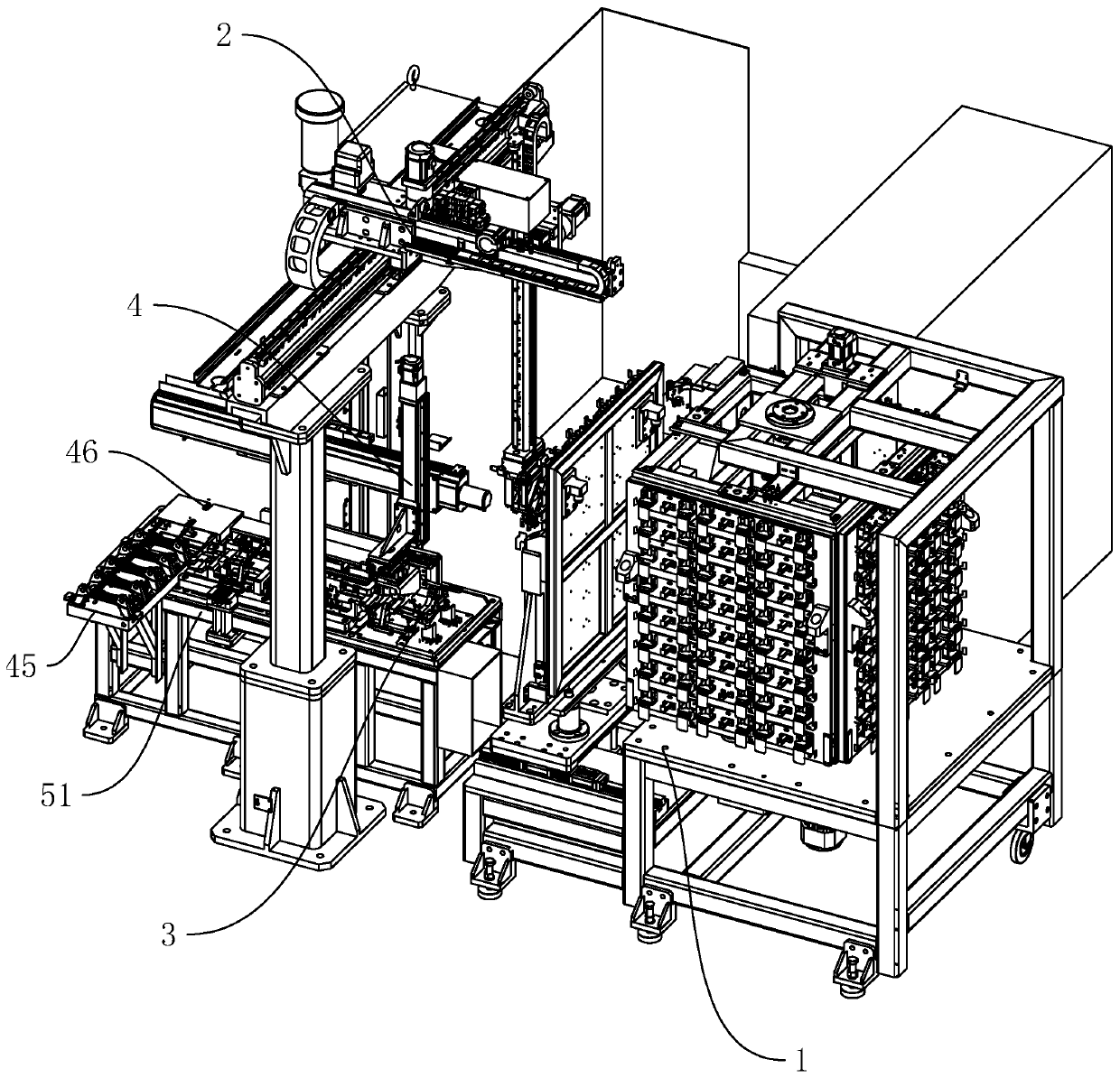

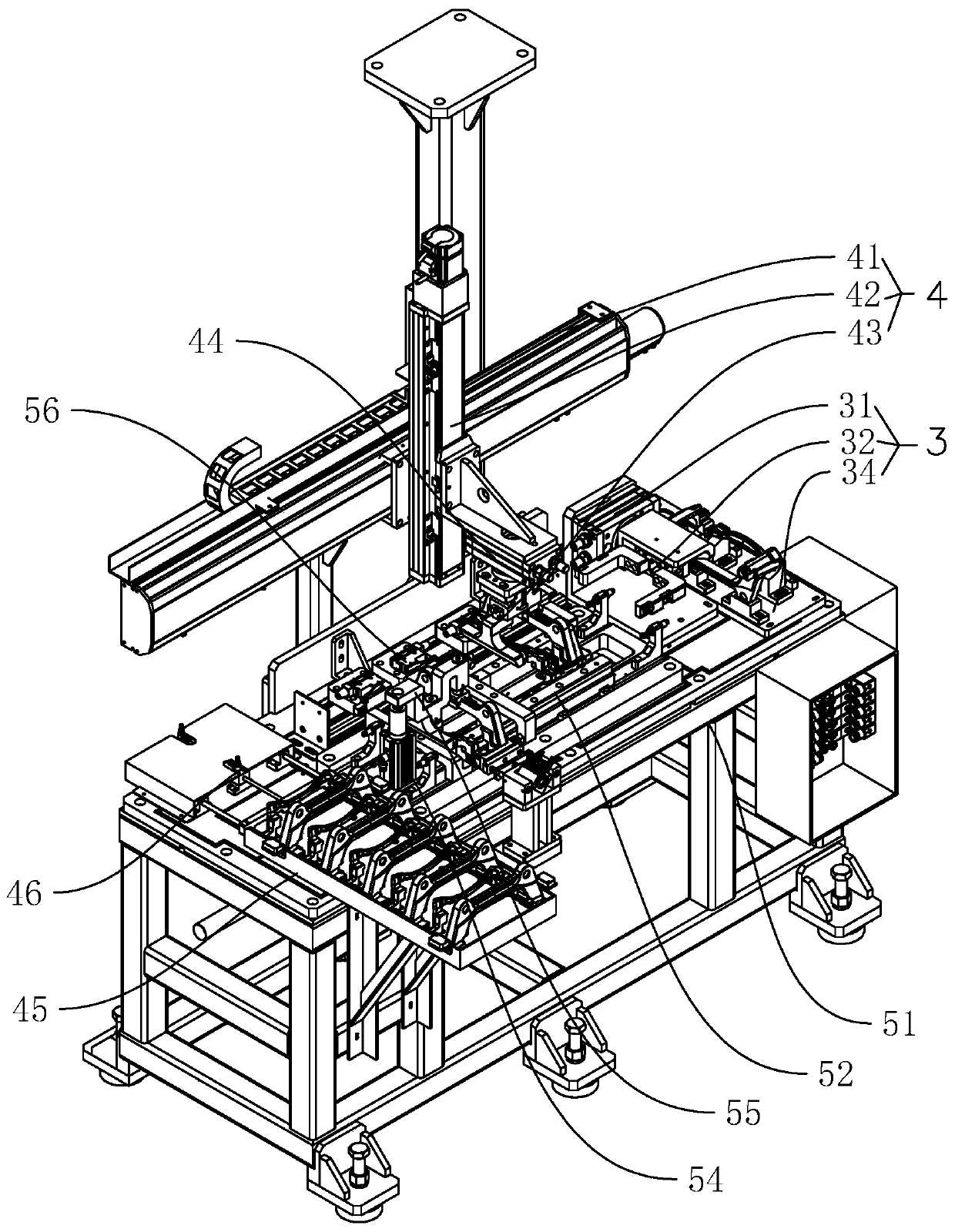

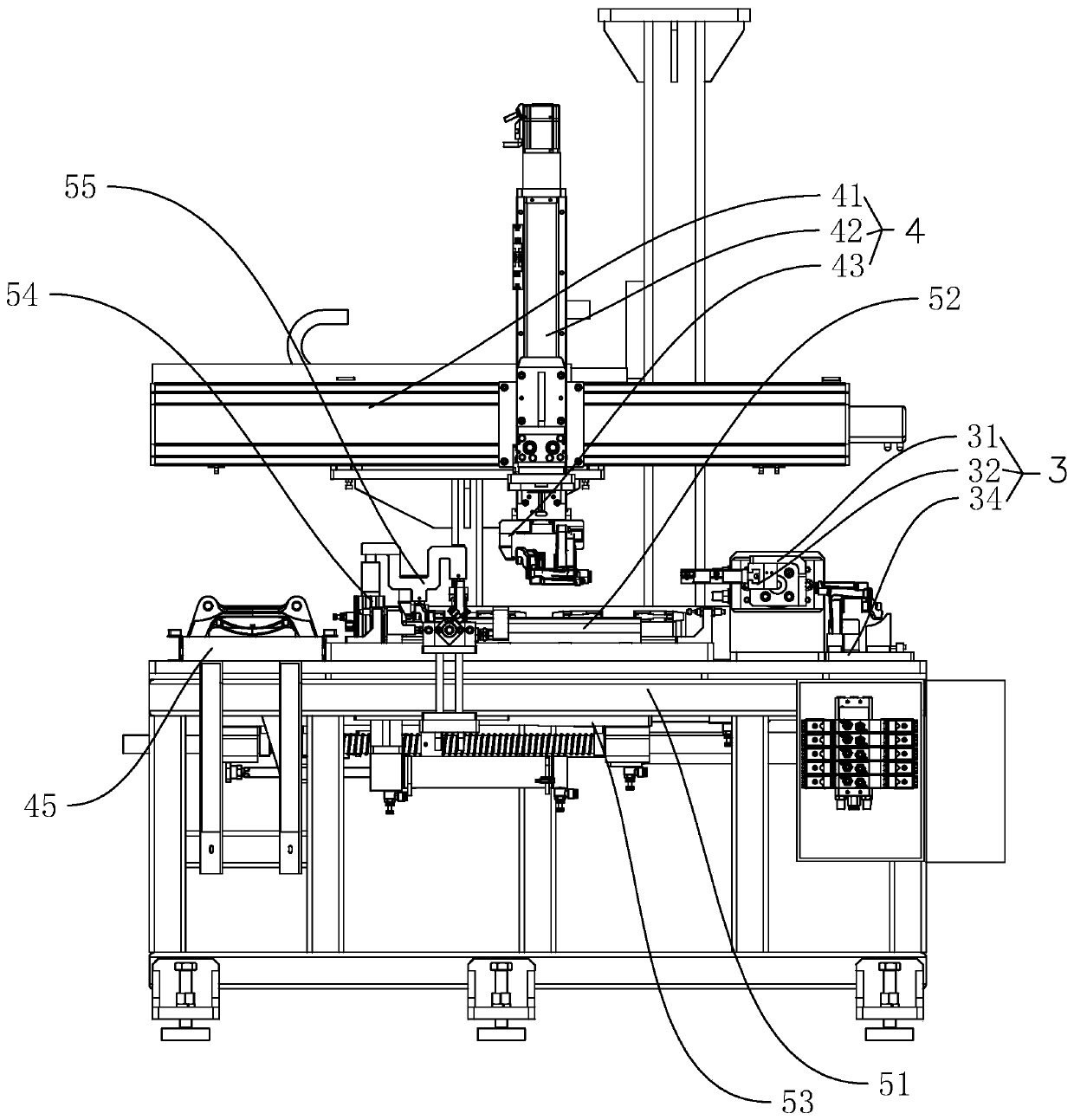

[0037] Detection device for automobile brake caliper bracket, such as figure 1 As shown, it includes workpiece silo 1, truss manipulator 2, turning mechanism 3, transfer mechanism 4 and detection mechanism, such as figure 2 , image 3 As shown, the detection mechanism includes a frame 51, two detection slide rails 52 fixed on the upper end surface of the frame 51 by bolts, at least two stroke touch switches 56 located beside one detection slide rail 52, and slidingly connected to two The detection pusher assembly between the detection slide rails 52, the distance between the two detection slide rails 52 gradually expands from one end to the other end, forming a detection principle similar to the no-go gauge, the detection pusher assembly includes a sliding connection to the frame 51 The pushing slide plate 53 on the lower surface, the pressing cylinder 54...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com