A cutting fluid recycling mechanism for machine tools

A cutting fluid and machine tool technology, which is applied in the field of machine tool cutting fluid recycling mechanism, can solve problems affecting electromagnet recovery, uneven dispersion performance, debris accumulation, etc., to improve uniformity, reduce metal debris content, reduce The effect of the jam probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

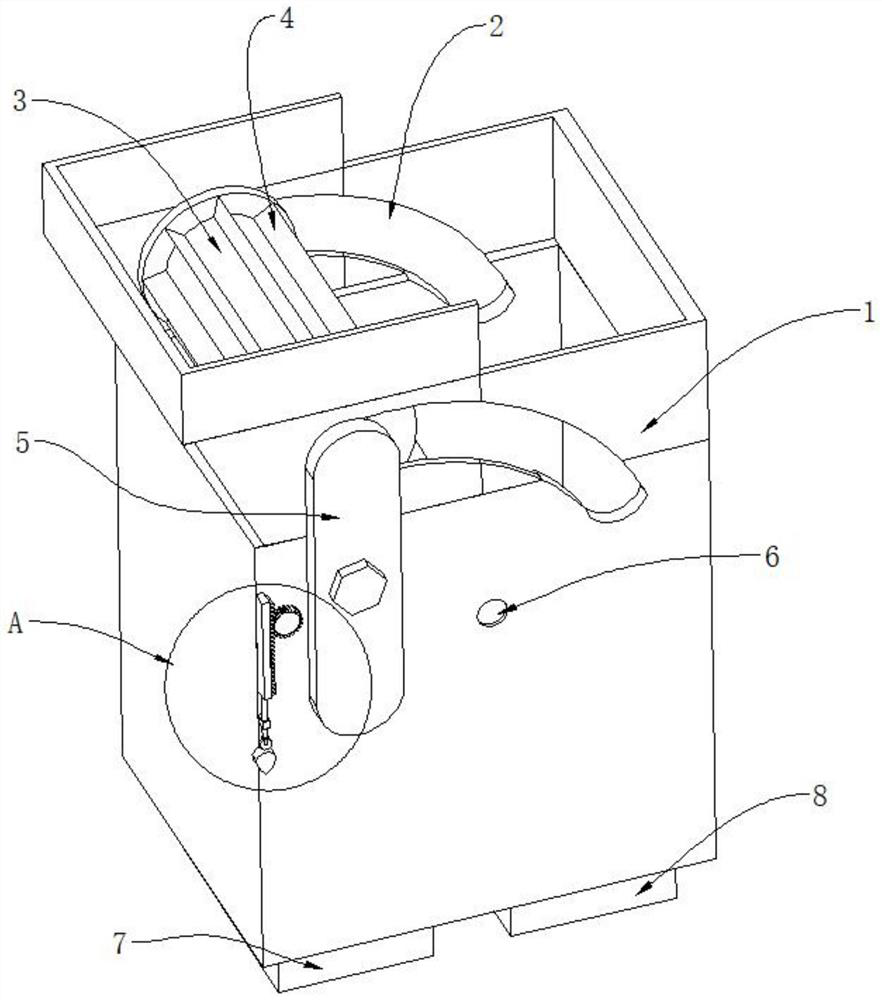

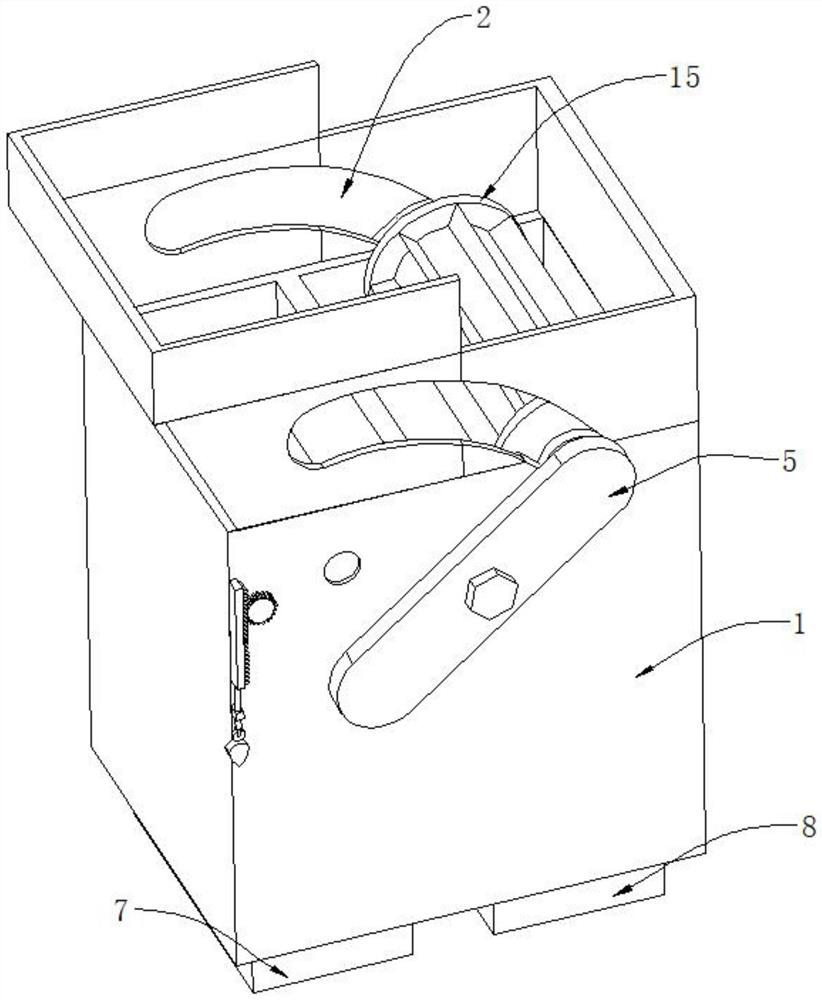

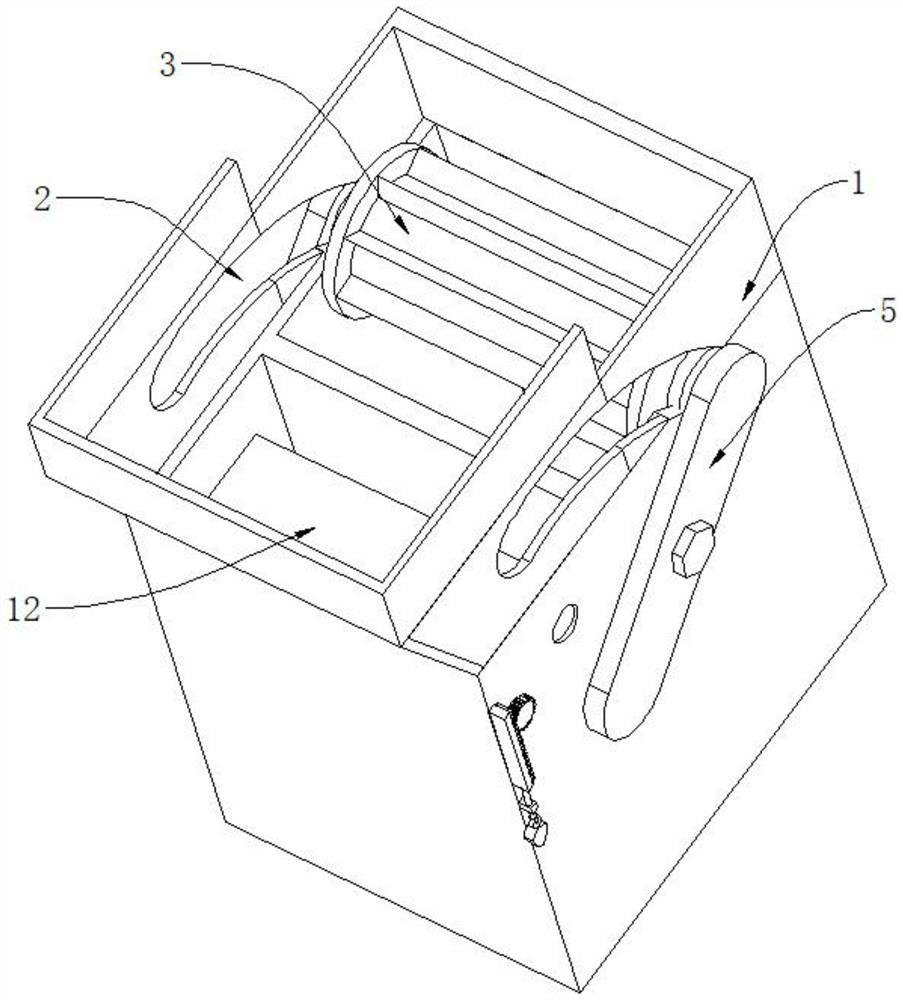

[0039]Such asFigure 1 to 6The cutting solution reuse mechanism shown is shown, including the tape opening of the case, and also includes a separator 14, connected to the inner side wall of the casing 1, separated into a waste liquid cavity and scrap cavity, and the separator There is a slot on 14 on 14;

[0040]The tank 2 is adjusted to the outer wall of the box 1;

[0041]The adjustment board 5 is rotatably connected to the outer side wall of the box 1;

[0042]The mounting hole 6 is opened in the outer wall of the casing 1;

[0043]The drive roller 3 is connected between the adjustment plate 5 by a connecting shaft disposed within the adjustment groove 2;

[0044]The electromagnet adsorption plate 4 is uniformly disposed on the outer side wall of the drive roller 3;

[0045]The blaming plate 12 is rotated by the rotation shaft to be attached to the inner side wall of the casing 1, and placed in the waste liquid chamber;

[0046]The first reciprocating adjustment assembly, the drive end of the first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com