Lightweight cable cover molding method embedded in winding shell

A molding method and cable cover technology, which are applied to household appliances, other household appliances, household components, etc., can solve the problems of poor heat insulation and erosion resistance, large negative mass, unreliable fixation of the cable cover, etc. Reduce negative mass, die design and ease of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

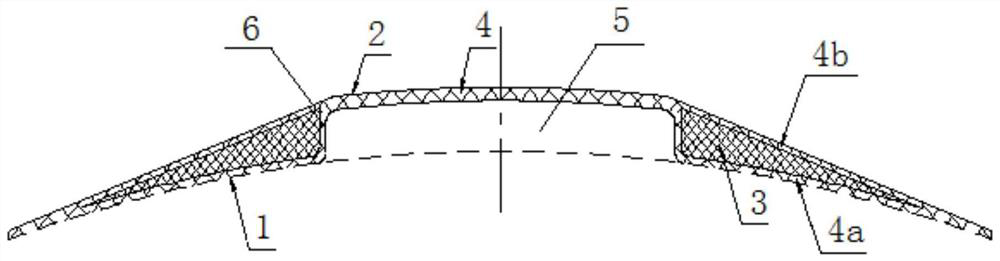

Image

Examples

Embodiment 1

[0035] The structural parameters of a certain type of lightweight cable cover embedded in the winding shell are shown in Table 1:

[0036] Table 1

[0037] serial number project Structural parameters 1 Radius of the arc surface of the inner surface 600mm 2 Hollow area cavity width 150mm 3 Hollow area cavity height 8mm 4 Cable Cover Width 300mm 5 Cable cover length 1535mm 6 The thickness of the structure layer under the foam 1.5mm 7 Thickness of foam upper structure layer 1.5mm

[0038] The lightweight cable cover molding method includes the following steps:

[0039] 1) According to the internal surface structure size of the cable cover and the length of the cable cover, the cable cover laying mold is made, and the cable cover laying mold is processed by Q235 structural steel.

[0040] 2) Add the PMI foam by machine. The transverse section of the PMI foam layer after machining is the same as the structur...

Embodiment 2

[0053] The structural parameters of a certain type of lightweight cable cover embedded in the winding shell are shown in Table 1:

[0054] Table 1

[0055] serial number project Structural parameters 1 Radius of the arc surface of the inner surface 400mm 2 Hollow area cavity width 80mm 3 Hollow area cavity height 8mm 4 Cable Cover Width 225mm 5 Cable cover length 3300mm 6 The thickness of the structure layer under the foam 1.2mm 7 Thickness of foam upper structure layer 1.2mm

[0056] The lightweight cable cover molding method includes the following steps:

[0057] 1) According to the internal surface structure size of the cable cover and the length of the cable cover, the cable cover laying mold is made, and the cable cover laying mold is processed by Q235 structural steel.

[0058] 2) Add PMI foam by machine, the transverse section of the PMI foam layer after machining is the same as the structure siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com