High-speed steel plate and production method thereof

A production method and high-speed steel technology, applied in the field of metallurgy, can solve the problems of serious trade deficit, difficult to break through in quality, and difficult for domestic die-casting enterprises to achieve good processing performance, ensure the performance of steel plates, and optimize the effect of heat treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

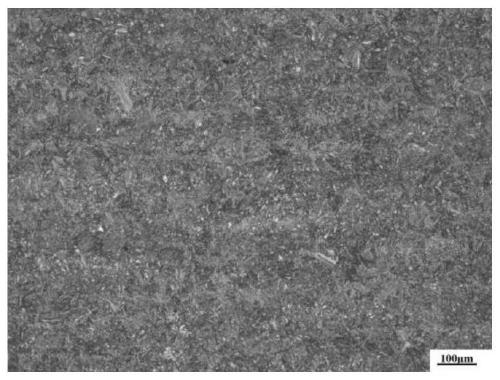

Embodiment 1

[0025] The thickness of the 145V33 high-speed steel plate in this embodiment is 12 mm, and its chemical composition and mass percentage are shown in Table 1.

[0026] The production method of the present embodiment 145V33 high speed steel plate comprises rolling and heat treatment process, and concrete process step is as follows:

[0027] (1) Rolling process: Hot rolling is used for production, the rolling temperature is 980°C, the final rolling temperature is 850°C, no watering after rolling;

[0028] (2) Heat treatment process: Heat treatment is carried out by quenching + tempering. The quenching process is firstly preheated at 800°C, kept for 30 minutes, then heated to quenching temperature of 1120°C within 5 minutes, holding time of 1.2min / mm and then oil cooled; The tempering process is that the steel plate is tempered 1 hour after quenching, the tempering temperature is 180°C, and the holding time is 3min / mm; the medium for steel plate quenching is a mixture of water and...

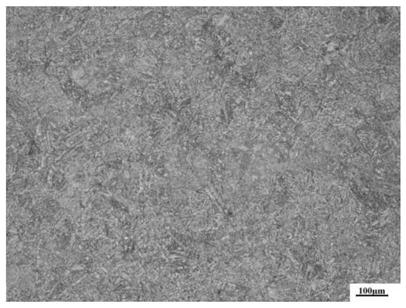

Embodiment 2

[0031] The thickness of the 145V33 high-speed steel plate in this embodiment is 18mm, and its chemical composition and mass percentage are shown in Table 1.

[0032] The production method of the present embodiment 145V33 high speed steel plate comprises rolling and heat treatment process, and concrete process step is as follows:

[0033] (1) Rolling process: Hot rolling is used for production, the rolling temperature is 1010°C, the final rolling temperature is 870°C, and no water is applied after rolling;

[0034] (2) Heat treatment process: Heat treatment is carried out by quenching + tempering. The quenching process is firstly preheated at 820°C, held for 39 minutes, then heated to the quenching temperature of 1160°C within 7 minutes, holding time of 1.3min / mm, and then oil cooled; The tempering process is that the steel plate is tempered 2 hours after quenching, the tempering temperature is 200°C, and the holding time is 3.5min / mm; the medium for steel plate quenching is a ...

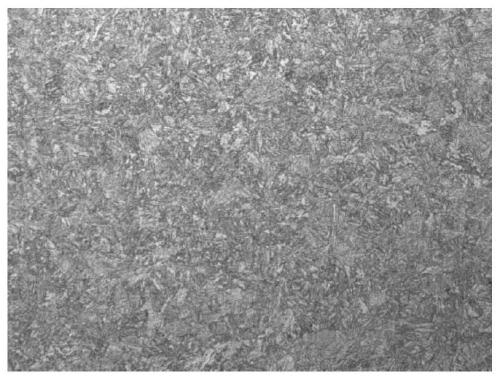

Embodiment 3

[0037] The thickness of the 145V33 high-speed steel plate in this embodiment is 21 mm, and its chemical composition and mass percentage are shown in Table 1.

[0038] The production method of the present embodiment 145V33 high speed steel plate comprises rolling and heat treatment process, and concrete process step is as follows:

[0039] (1) Rolling process: Hot rolling is used for production, the rolling temperature is 1020°C, the final rolling temperature is 880°C, no watering after rolling;

[0040] (2) Heat treatment process: Heat treatment is carried out by quenching + tempering. The quenching process is firstly preheated at 830°C, held for 42 minutes, and then heated to the quenching temperature of 1180°C within 9 minutes, holding time of 1.45min / mm and then oil cooled; The tempering process is that the steel plate is tempered 3 hours after quenching, the tempering temperature is 200°C, and the holding time is 3.8min / mm; the medium for steel plate quenching is a mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com