Environment-friendly plastic runway and its construction technology

A technology of plastic runway and construction technology, applied in the direction of roads, roads, road repair, etc., can solve problems such as affecting the construction period, and achieve the effect of convenient control of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

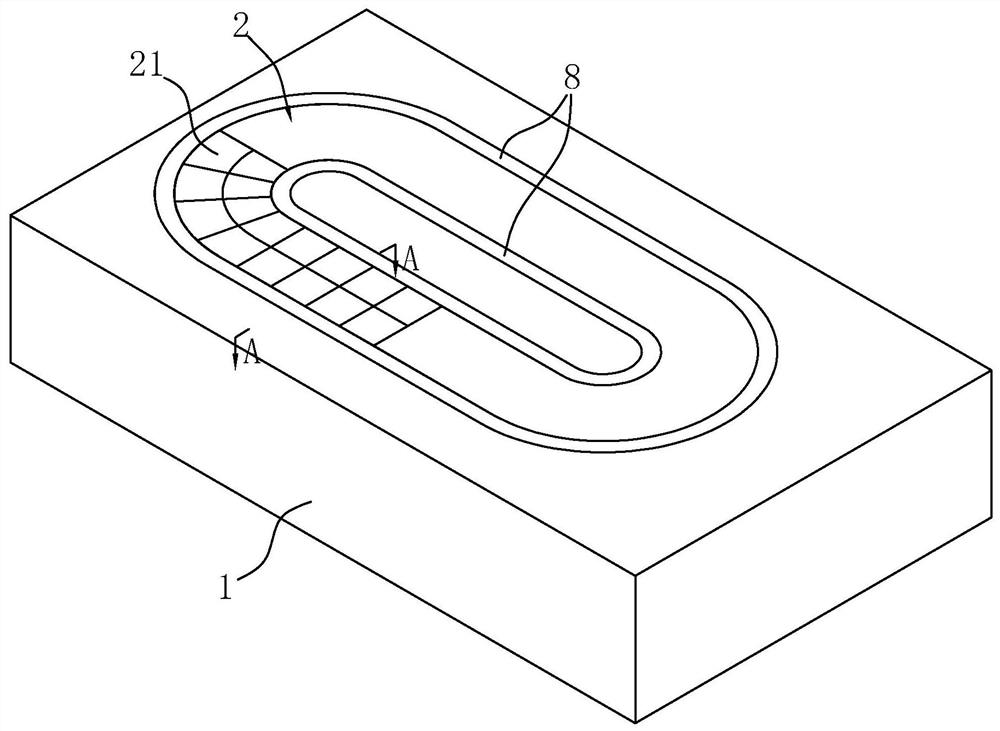

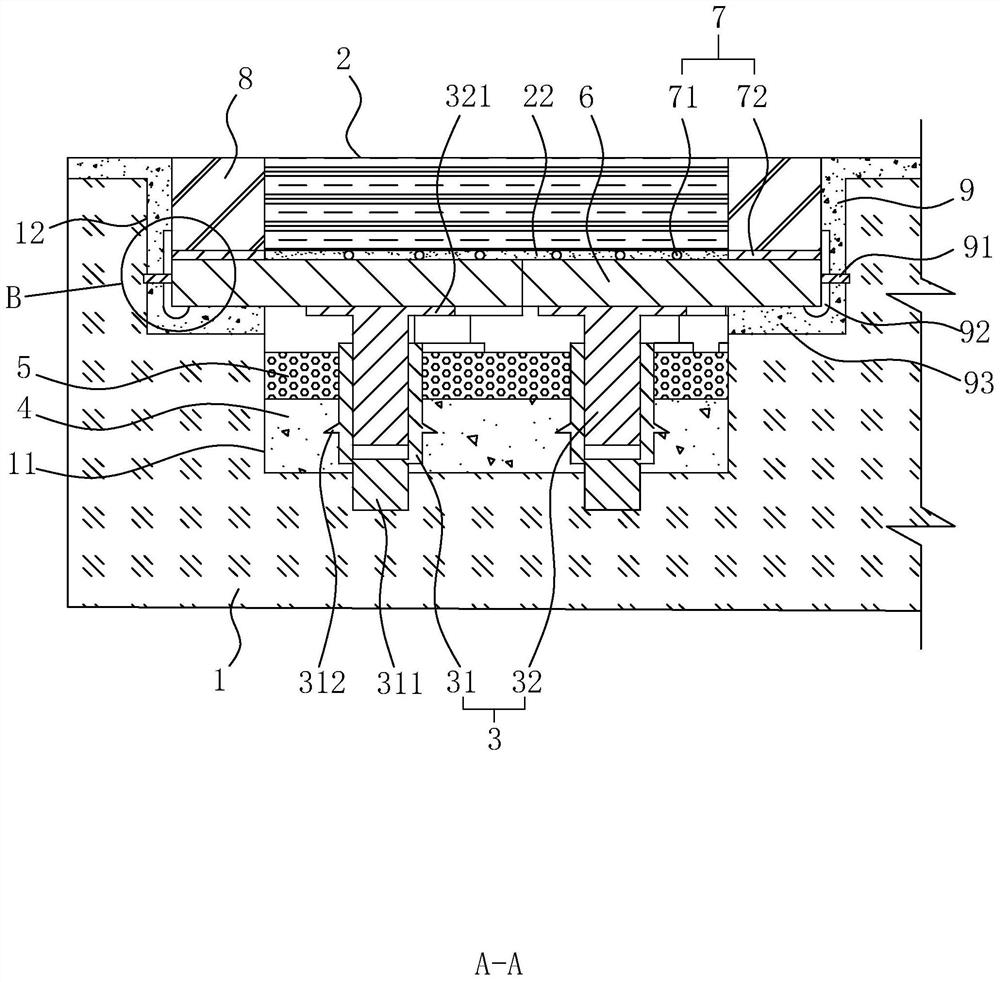

[0044] Example: An environmentally friendly plastic runway, such as figure 1 with figure 2 As shown, the annular foundation pit 11 is excavated on the foundation design size, and then the open both sides of the foundation pit 11 is symmetric to form a broadening groove 12, and a plurality of support components are fixed vertically in the bottom of the foundation pit 11. 3. The concrete layer 4 and the gravel layer 5 are sequentially laid in the foundation pit 11, and the support assembly 3 is distingurated from the bottom wall of the widening groove 12 on the same horizontal plane, support assembly 3 supports support plate 6. The end portion of the support plate 6 abuts the widening groove 12 and fixed, and the support plate 6 is sequentially laid, and the top surface of the plastic layer 2 is flush, and the plastic layer 2 is fixed. There is a block 8.

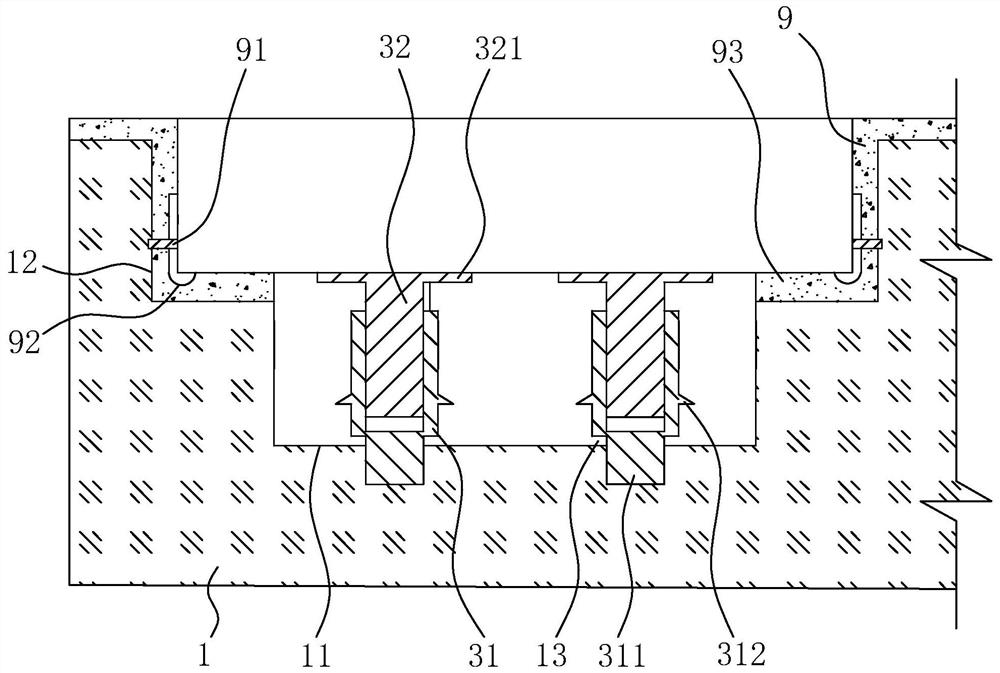

[0045] reference figure 2 with image 3 The support assembly 3 includes a support base 31 that is fixedly coupled to the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com