Method for forming liquid cavity through adding of multi-part middle spacing sleeve

A petal type and spacer technology, which is applied in the direction of mechanical equipment, shock absorbers, springs, etc., can solve the problems of large wheel rail and line wear, small stiffness performance, and high maintenance costs, and achieve optimal product performance, small radial stiffness, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

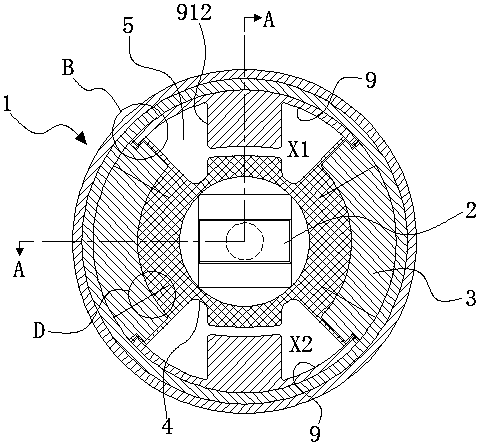

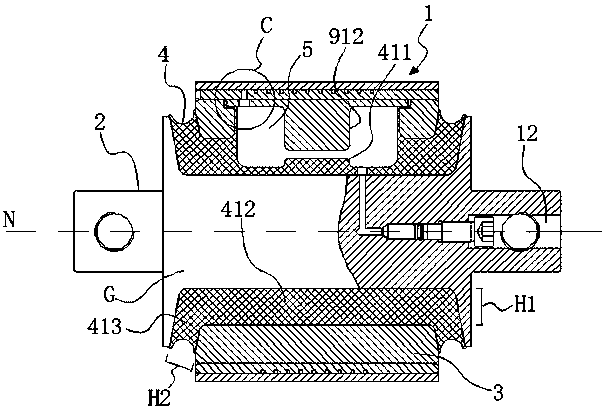

[0041] Embodiment 1: as figure 1 with figure 2 As shown, the liquid rubber composite node involved in the present invention includes an outer jacket 1, a mandrel 2 and a multi-lobed middle spacer 3 between the outer jacket 1 and the mandrel 2, and the multi-lobed middle spacer 3 and the mandrel 2. Bond together by vulcanization of rubber 4, and then assemble the integrated multi-lobed middle spacer and mandrel into the outer casing 1; set the flow channel in the outer casing 1, and hollow out the multi-lobe middle spacer 3 to form A plurality of spaces, when vulcanized, utilize rubber 4 and the plurality of spaces to form a plurality of liquid cavities 5 independent of each other, liquid (not shown in the figure) is arranged in the plurality of liquid cavities 5 and the plurality of liquid cavities The cavities 5 are connected through flow channels.

[0042] A method of forming a liquid cavity by adding a multi-lobed intermediate spacer provided in this embodiment is to hol...

Embodiment 2

[0058] Embodiment 2: as Figure 9 As shown, compared with Embodiment 1, the difference is that in this embodiment, a two-petal intermediate spacer 3 is used, including an upper arc-shaped petal body 313 and a lower arc-shaped petal body 314 .

Embodiment 3

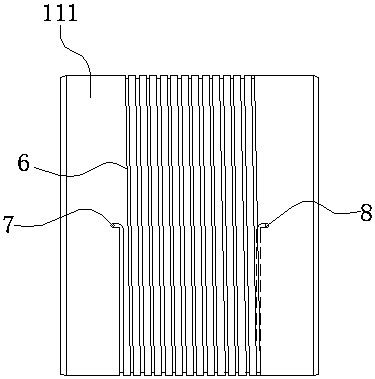

[0059] Embodiment 3: as Figure 10 to Figure 12 As shown, compared with Embodiment 1, the difference lies in that the design structure of the flow channel is different. In this embodiment, the flow channel is formed as follows: the mandrel 2 is divided into inner and outer parts, the inner part is the mandrel body 212, and the outer part is the mandrel jacket 213, and the mandrel body 212 is interference fitted to the mandrel jacket 213 in. Runner grooves 6 are arranged on the outer peripheral surface of the mandrel body 212, and the runner grooves 6 are spirally distributed on the outer peripheral surface of the mandrel body 212. Here, the runner grooves 6 may not be spirally surrounded, Instead it is set in other shape. When the mandrel body 212 is interference-fitted into the mandrel outer cover 213, the inner peripheral surface of the mandrel outer cover 213 is used to block and seal the notch of the flow channel groove 6 to form an inner groove flow channel, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com