Open type detection device and method for surface shape and parallel difference of large-size optical window part

An optical window and detection device technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problem of affecting the processing accuracy and processing efficiency of large-sized window parts, unable to test the surface shape and parallel difference of large-sized window parts, and parts polishing. Surface damage and other problems, to achieve the effect of broadening the test range, simple structure, and increasing the rotation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

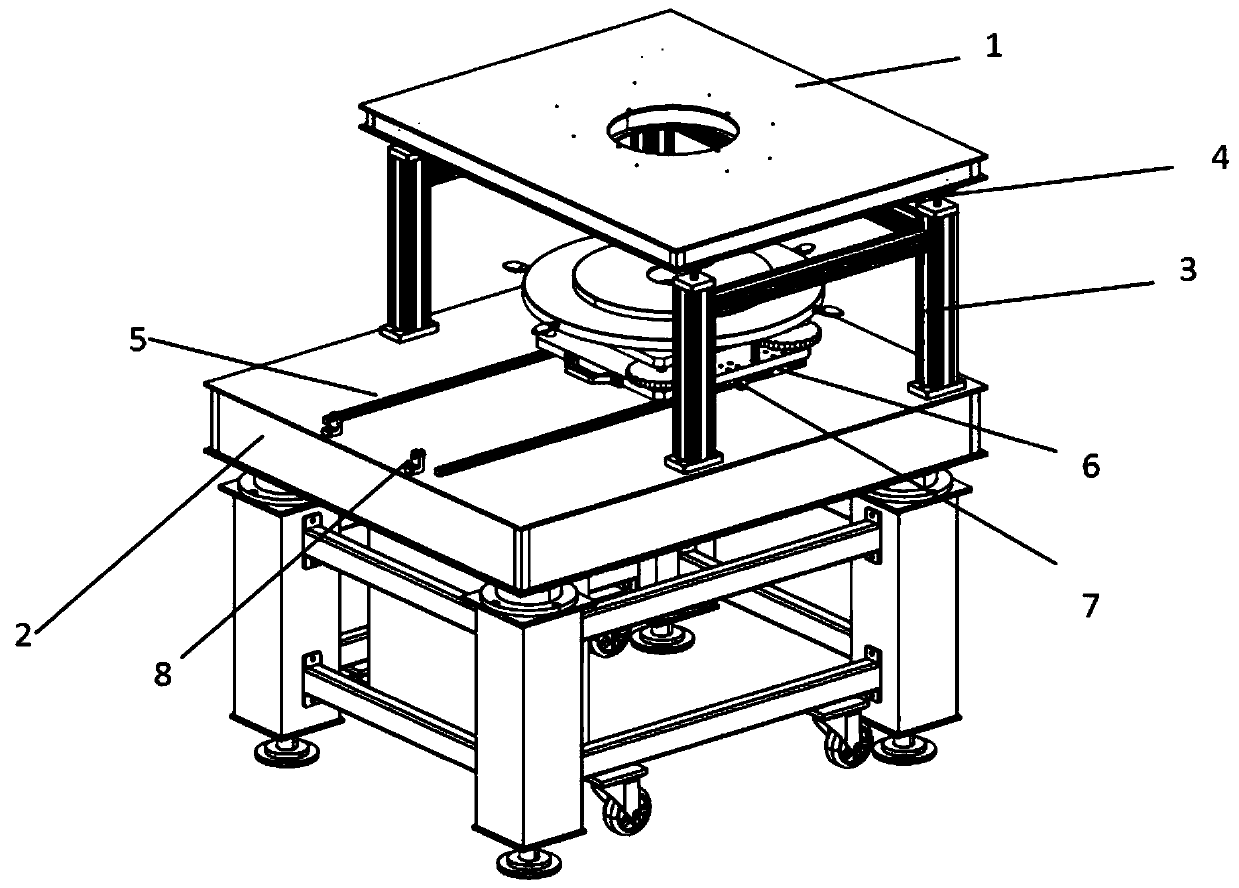

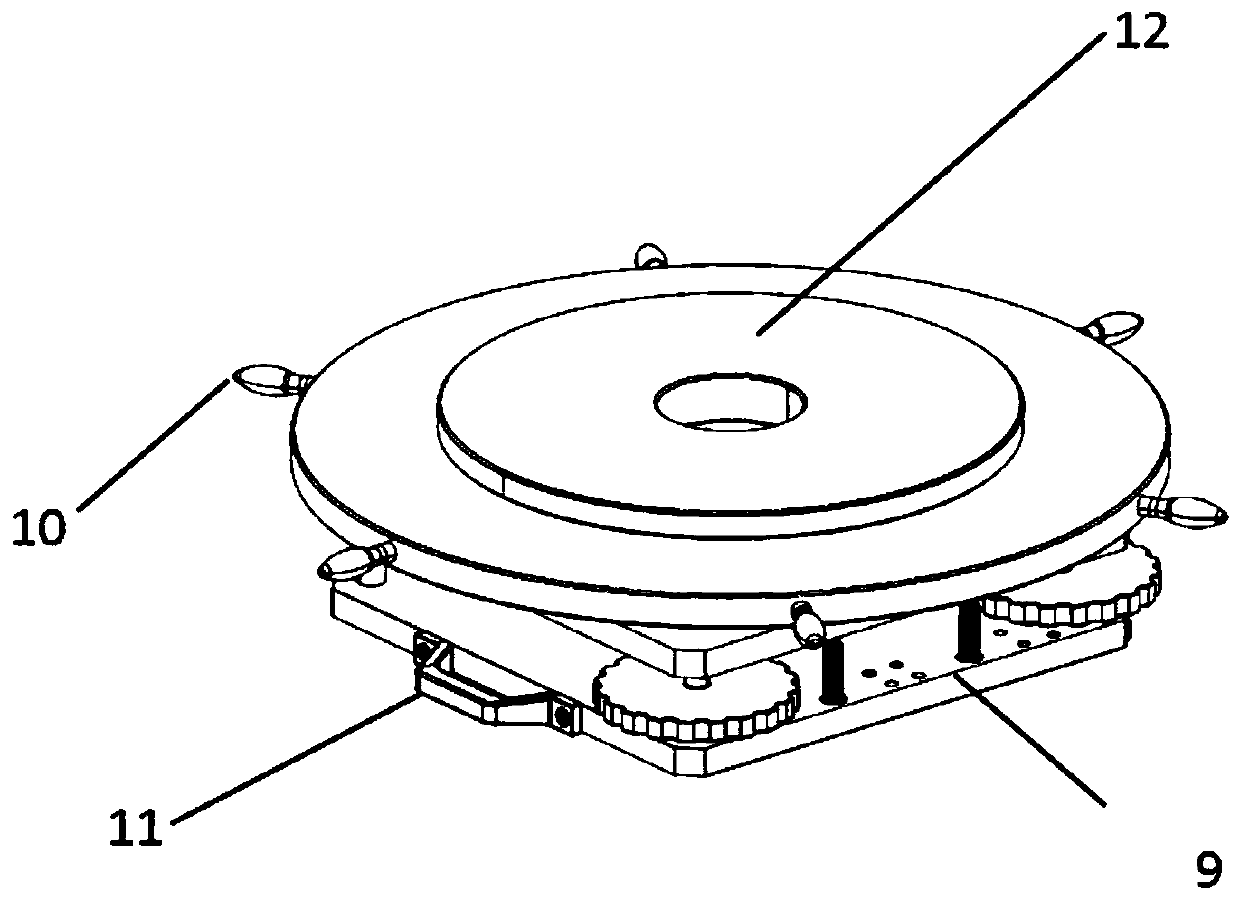

[0033] Aiming at the problems existing in the detection of surface shape and parallelism of large-size window parts in the optical workshop, the invention designs a Fizeau type laser plane interferometer with simple structure, convenient operation, light product installation, and open design, which can realize A device and a detection method for the open detection of the surface shape and parallelism of a large-size window part.

[0034] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0035] In describing the present invention, it should be understood that the terms "center", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "front", " Orientation indicated by rear, left, right, vertical, horizontal, top, bottom, inside, outside, clockwise, counterclockwise, etc. The positional relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com