Battery top cover processing method

A processing method and technology of the top cover, applied in the direction of battery cover/end cover, battery pack components, battery box/jacket, etc., can solve the problems of battery quality impact, harm, etc., to ensure safe use, reduce production costs, reduce effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for processing a battery top cover, comprising the following steps;

[0037] Step 1: Install the explosion-proof valve in the explosion-proof valve interface on the cover plate, and use point laser to detect the height difference between the upper surface of the explosion-proof valve and the upper surface of the cover plate. If the height difference is within the preset range, it is a qualified product;

[0038] Step 2: Perform laser welding on the explosion-proof valve cover plate of the qualified product obtained in step 1 to obtain the top cover of the semi-finished battery, conduct semi-finished helium inspection on the top cover of the semi-finished battery, place the top cover of the semi-finished battery in the gas inspection fixture, and install the fixture The cylinder presses the top cover of the semi-finished battery, sprays compressed air into the cavity below the top cover of the semi-finished battery and maintains the pressure, and detects the leak...

Embodiment 2

[0044] A method for processing a battery top cover, wherein the battery top cover includes a top cover sheet, a lower plastic, a positive electrode assembly, a negative electrode assembly, a sealing ring, an explosion-proof valve, and an explosion-proof valve protection patch;

[0045] The method for processing the battery top cover includes the following steps:

[0046] Step 1: Top cover sheet loading, grab the cover plate to the fine positioning position for fine positioning, transfer the product from the fine positioning position to the double-speed chain carrier for loading; laser coding, clean the top cover sheet coding area after coding is completed ;The manipulator takes out the top cover sheet, and uses point laser to detect the height difference between the explosion-proof valve and the cover plate. Unqualified products are not welded at the welding station, and the height difference is within the preset range as qualified products;

[0047]Step 2: Perform laser weldi...

Embodiment 3

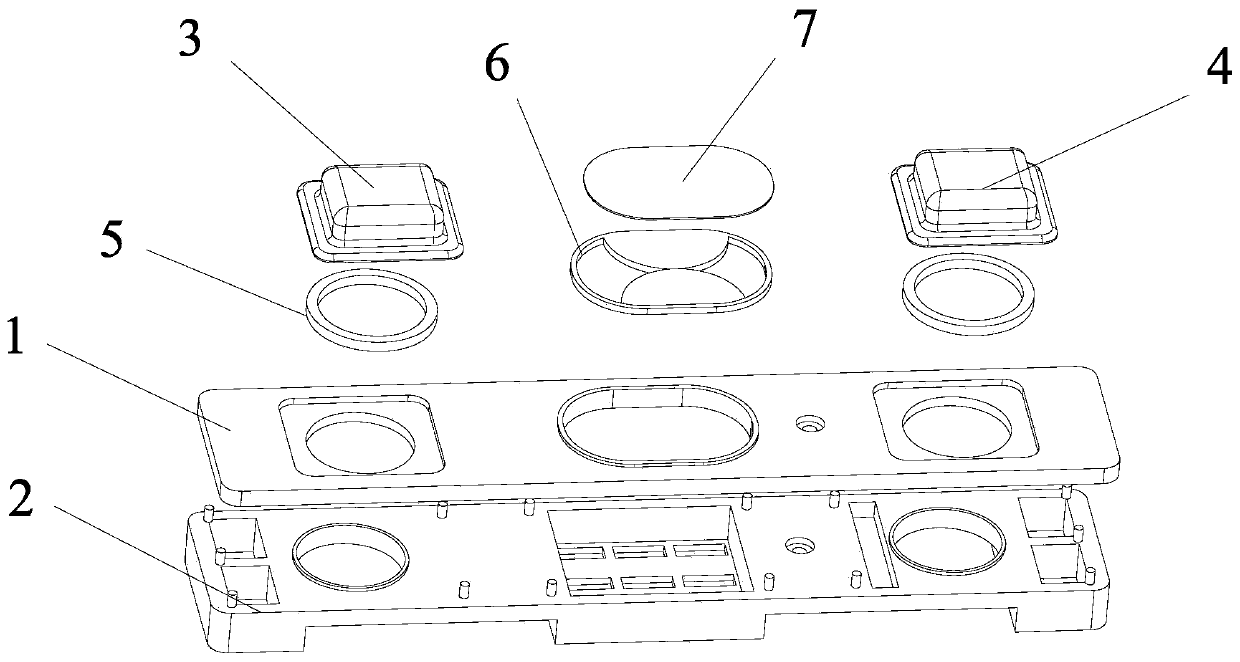

[0054] refer to figure 1 , a method for processing a battery top cover, the battery top cover comprising, a top cover sheet, a lower plastic, a positive electrode assembly, a negative electrode assembly, a sealing ring, an explosion-proof valve, and an explosion-proof valve protection patch;

[0055] The method for processing the battery top cover includes the following steps:

[0056] 1. Top cover sheet loading: Servo mechanism, CCTL mechanism and module are used to transfer and load materials, and the full tray is manually loaded on the TRAY tray for loading (6 top cover sheets are loaded at a time), and the module grabs the cover plate Go to the fine positioning position for fine positioning, the module transfers the product from the fine positioning position to the double-speed chain carrier for loading, and manually empty the tray.

[0057] 2. Laser coding: Double laser coding is automatically coded online simultaneously (the coding machine is fixed, and each laser head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com