Annular mechanical welding device

A mechanical welding and circular technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of reducing welding efficiency, increasing the construction cost of welding line, and not covering the welding work of workpieces to be welded well. The effect of high flexibility and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

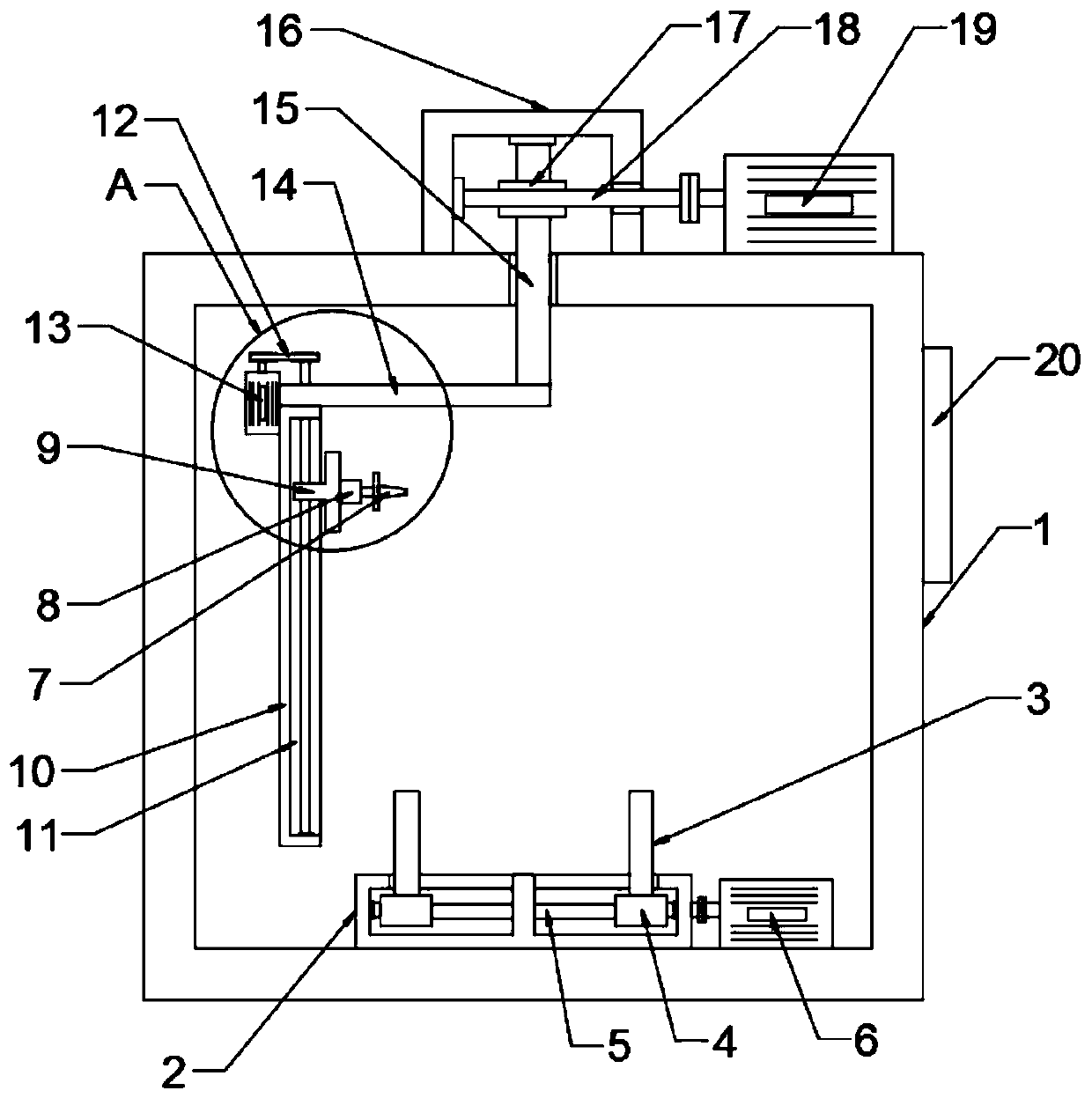

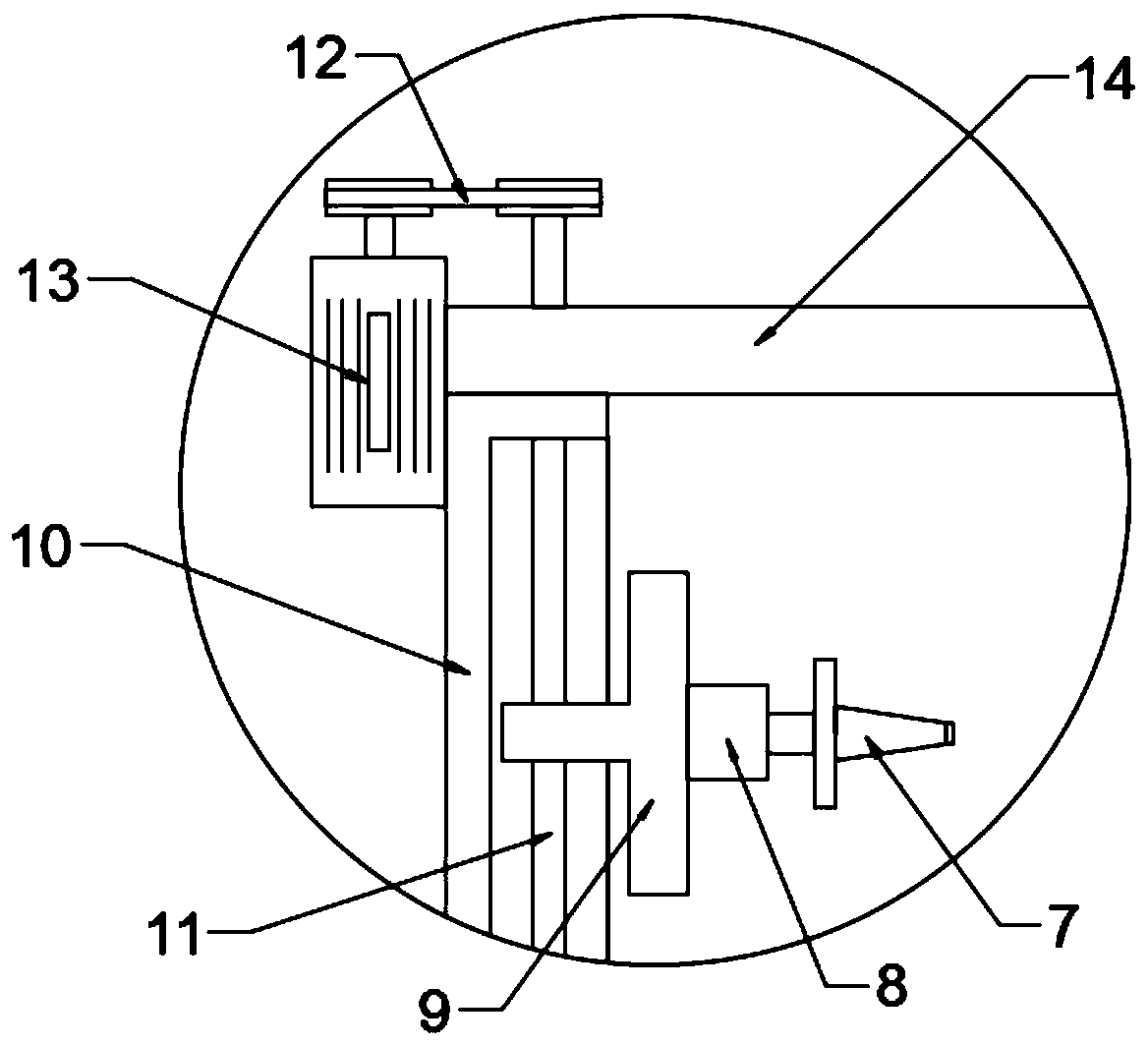

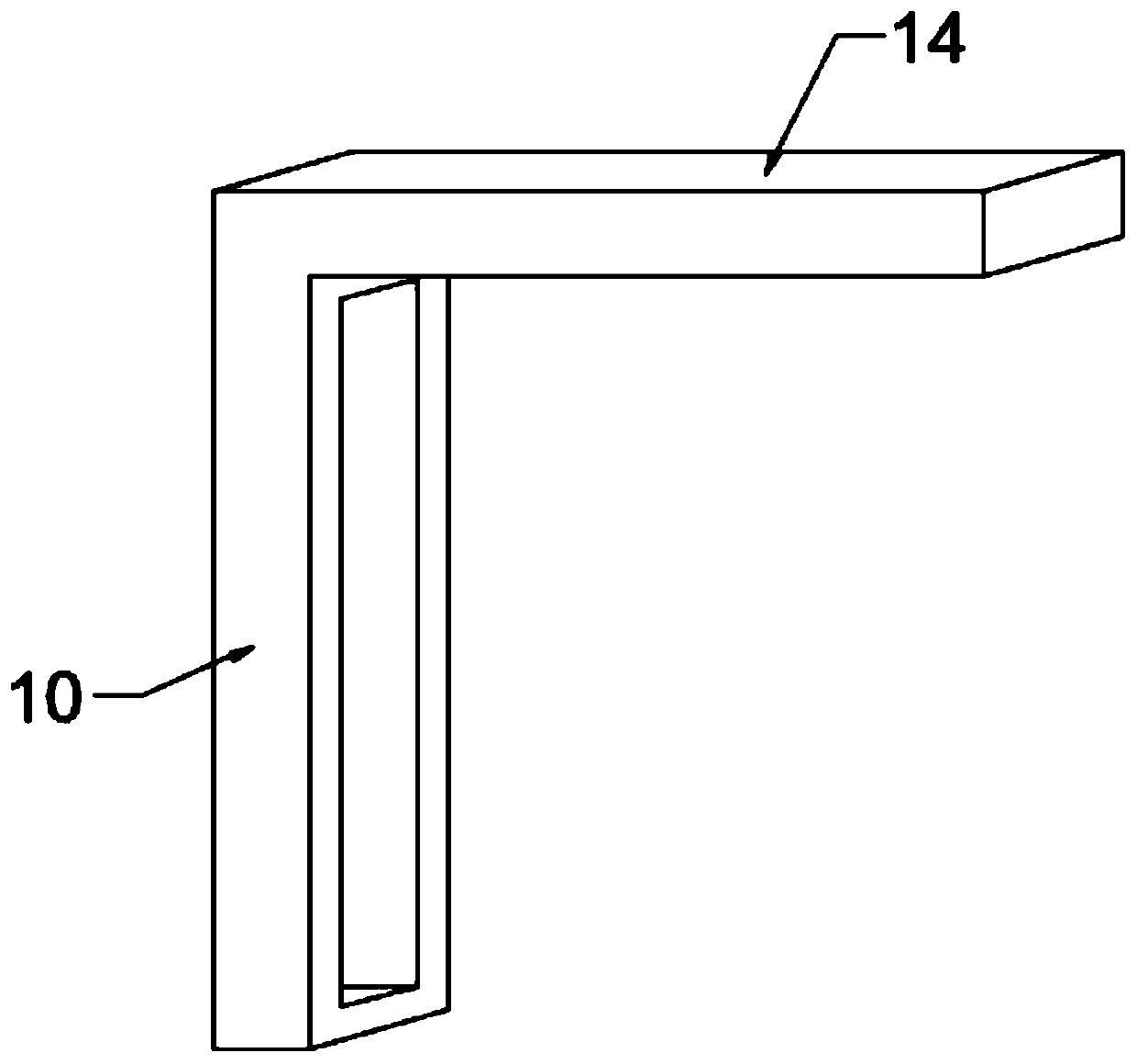

[0019] see Figure 1-3 , in an embodiment of the present invention, a ring-shaped mechanical welding device includes a box body 1; a welding torch 7 is arranged in the box body 1, and the welding torch 7 is connected to an external electric welding machine through a wire; the welding torch 7 is fixedly connected to an electric telescopic rod 8. The electric telescopic rod 8 is fixedly connected with a lifting block 9, and the electric telescopic rod 8 is used to adjust the horizontal position of the welding torch 7; the lifting block 9 is nested with a vertical plate 10, and the vertical plate 10 is provided with a vertical chute, The vertical chute is provided with a screw mandrel 11, the screw mandrel 11 runs through the lifting block 9 and is threadedly connected with the lifting block 9, the screw mandrel 11 extends to the top of the vertical plate 10 and is connected with a second screw mandrel motor 13 by a transmission belt 12, The second screw motor 13 is electrically ...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that: a clamping seat 2 is provided below the welding torch 7, and a clamping plate 3 is arranged symmetrically above the clamping seat 2, and a moving block 4 is fixedly connected to the bottom of each clamping plate 3 , the moving block 4 is nested in the clamping seat 2, the clamping seat 2 is provided with a horizontal chute, the horizontal chute is provided with a two-way screw rod 5, and the two-way screw rod 5 runs through the moving block 4 and is threadedly connected with the moving block 4; The two-way screw 5 extends to the outside of the clamping seat 2 and is connected to the output shaft of the first screw motor 6 through a coupling. The first screw motor 6 is connected to the controller 20 through a wire. The first screw motor 6 Electrically connected with an external power supply, the first screw motor 6 drives the bidirectional screw 5 to rotate, and the bidirectional screw 5 drives the symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com