Method for preparing liquid paraffin by hydrogenating waste animal and plant oil

A technology of discarded animals and plants and liquid paraffin, which is applied in the field of hydrogenation of waste animal and vegetable oils to prepare liquid paraffin, which can solve the problems of poor fluidity at low temperature and cannot be used in areas with low temperature, and achieves the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

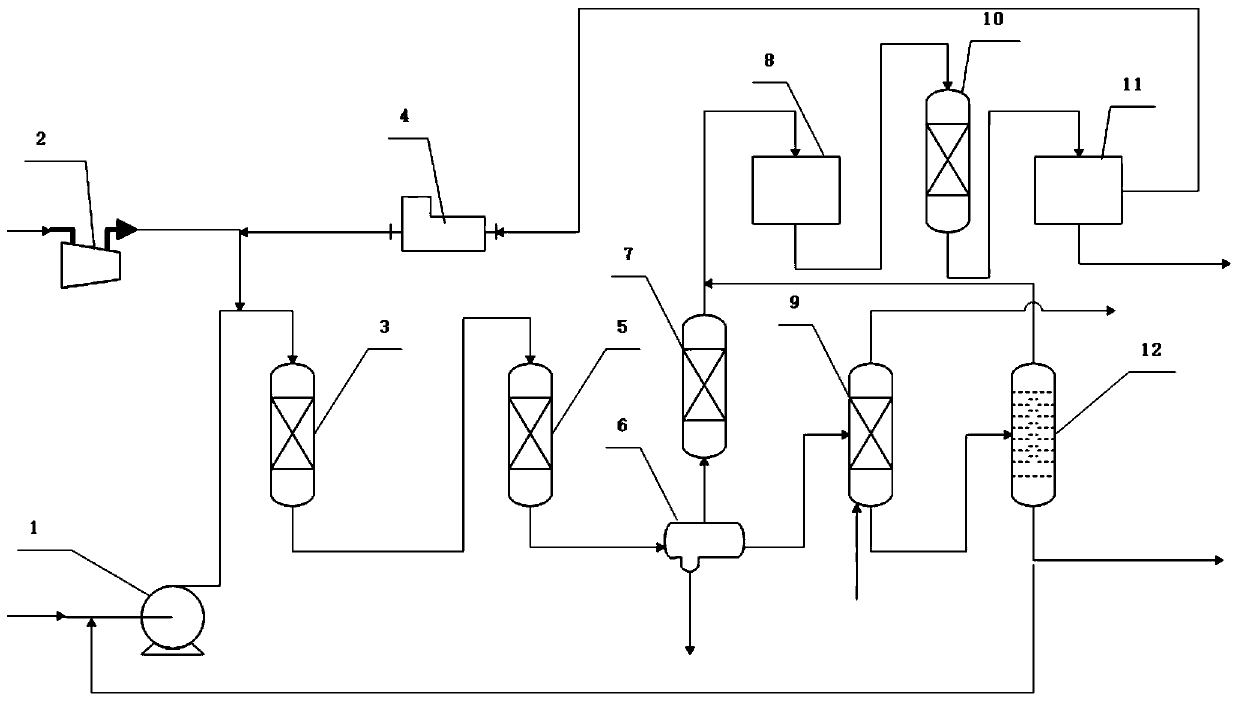

[0024] The method of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereby.

[0025] Hydrogenation of waste animal and vegetable oils to prepare liquid paraffin, the steps are:

[0026] a) waste animal and vegetable fats and oils are uniformly mixed with environment-friendly liquid paraffin to obtain a mixture; wherein, the environment-friendly liquid paraffin accounts for 10wt% to 90wt% of the waste animal and vegetable oils;

[0027] b) The mixture obtained in step a) is fed into the hydrofinishing reactor 3 through the feed pump 1, and the hydrogen enters the hydrofinishing reactor 3 after being compressed by the new hydrogen compressor 2, and the hydrofinishing reaction is carried out in the presence of the hydrofinishing catalyst;

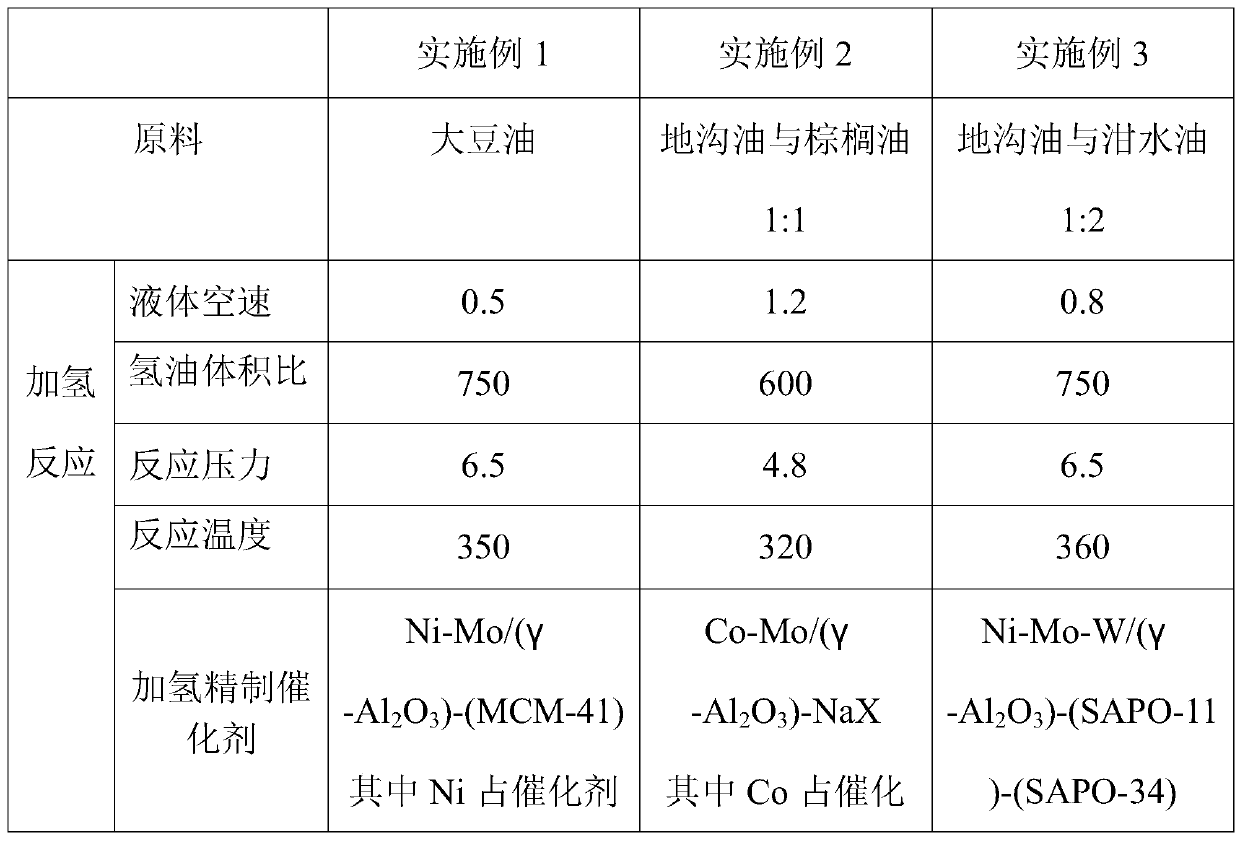

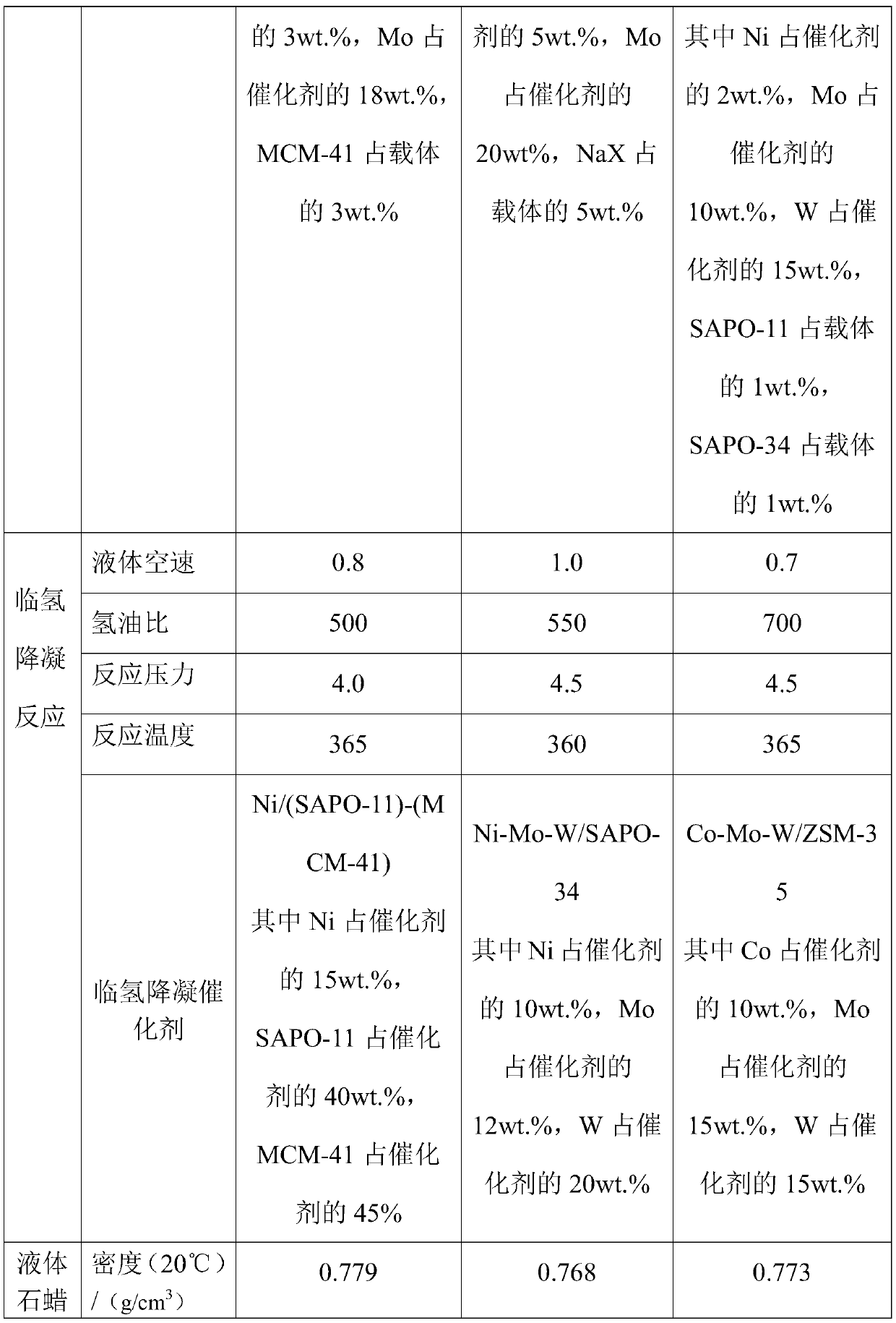

[0028] Described hydrofining reaction, its reaction condition is: liquid space velocity 0.5~2h -1 , the volume ratio of hydrogen to oil is 500:1~2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com