A kind of electrostatic cotton material and its preparation method and application

A technology of electrostatic cotton and raw materials, applied in the field of electrostatic cotton materials, can solve the problems of strong odor, obvious static attenuation, poor durability, etc., and achieve the effects of strong charge retention capacity, low high-temperature filter effect attenuation, and beautiful cloth style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

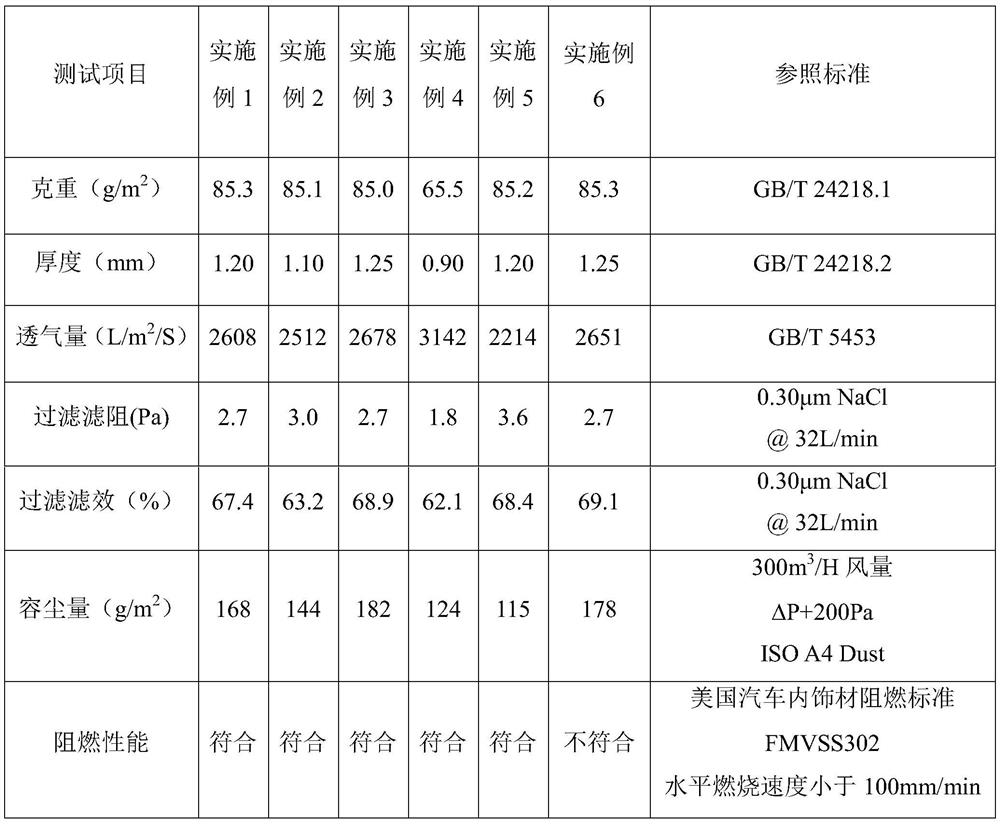

Examples

Embodiment 1

[0055] The A component polymer is a homopolymeric polypropylene with a melting point of 158 to 168 °C;

[0056] The B component polymer is a polyester chip treated with phosphorus-based flame retardant modification, the melting point is 235 to 255 ° C, and the oxygen index is greater than

[0060] The B component polymer (flame retardant) is melted through a single-screw extruder, and its temperature zone is set as: 280 ° C, 282 ° C,

[0061] The temperature of the closed box for melt distribution in the composite spinning pack was maintained at 285°C;

Embodiment 2

[0064] The A component polymer is a homopolymeric polypropylene with a melting point of 158 to 168 °C;

[0065] The B component polymer is a polyester chip treated with phosphorus-based flame retardant modification, the melting point is 235 to 255 ° C, and the oxygen index is greater than

[0070] The temperature of the closed box for melt distribution in the composite spinning pack was maintained at 285°C;

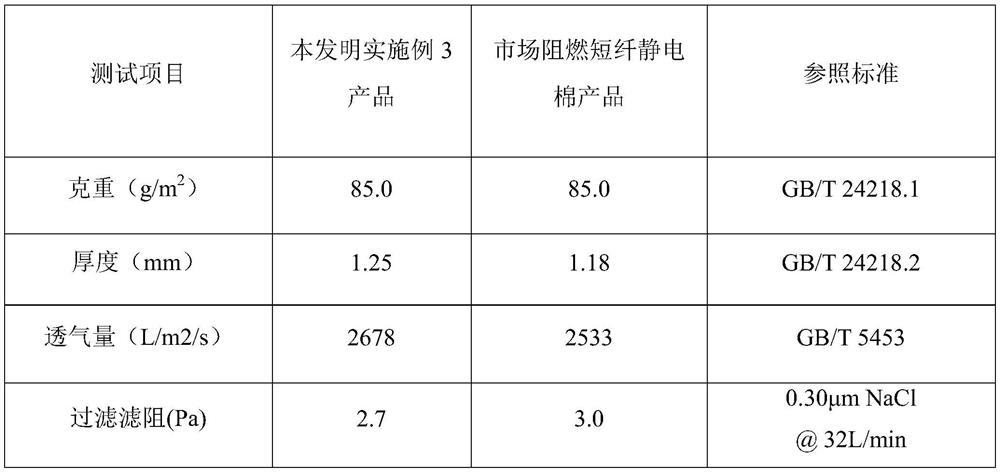

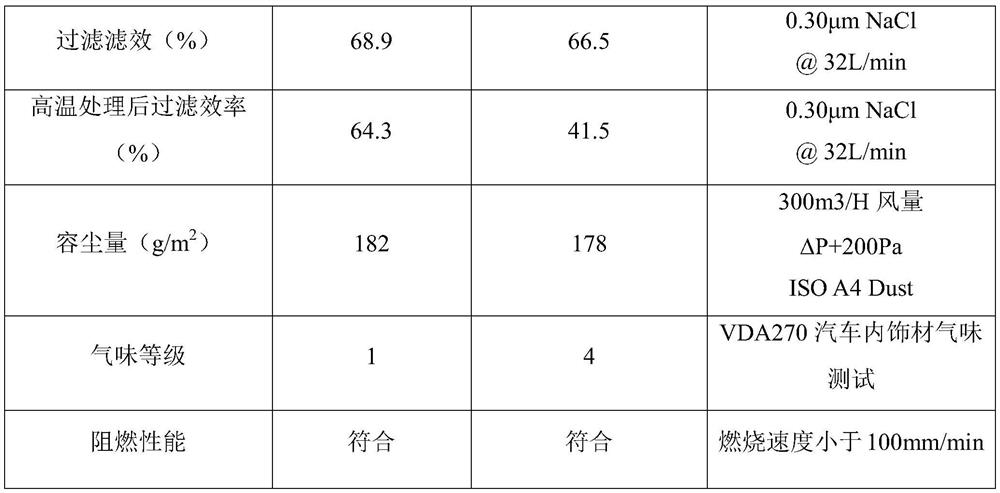

Embodiment 3

[0073] The A component polymer is a homopolymeric polypropylene with a melting point of 158 to 168 °C;

[0074] The B component polymer is a polyester chip treated with phosphorus-based flame retardant modification, the melting point is 235 to 255 ° C, and the oxygen index is greater than

[0078] The B component polymer (flame retardant) is melted through a single-screw extruder, and its temperature zone is set to: 280° C., 282° C.,

[0079] The temperature of the closed box for melt distribution in the composite spinning pack was maintained at 285°C;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com