Spiral wave electromagnetic acceleration plasma source

A plasma source and helical wave technology, which is applied in the directions of plasma, plasma, ion beam tube, etc., can solve the problems of restricting the life of the thruster, low acceleration efficiency, and large acceleration area, and achieves the realization of thrust controllability, The effect of eliminating electrode corrosion and improving diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the following embodiments are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

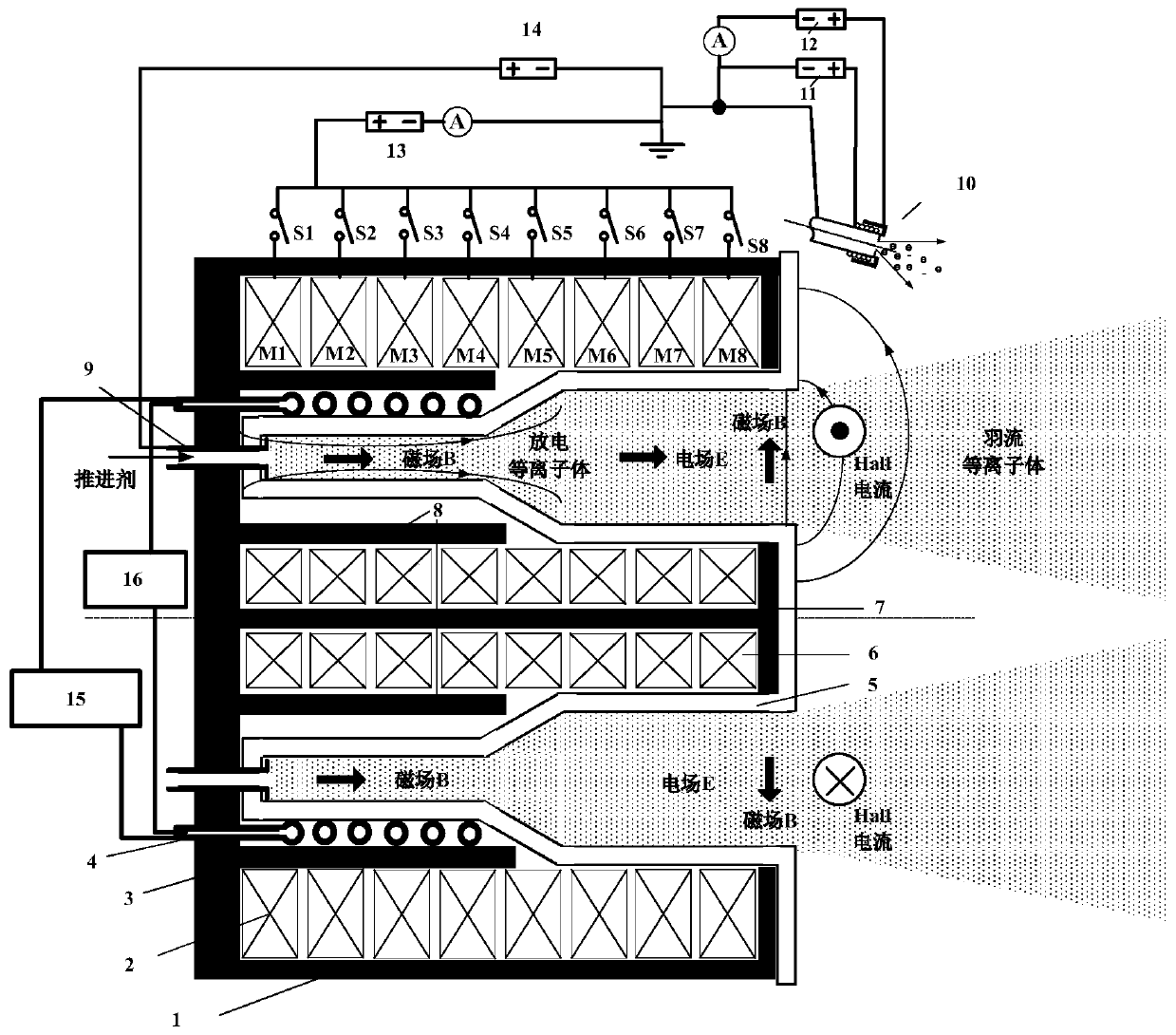

[0031] Such as figure 1 As shown, the helicon wave electromagnetic accelerated plasma source of the present invention has a cylindrical shape as a whole, and sequentially includes an outer magnetic shield 1, an outer magnetic coil group 2, an inner magnetic shield 3, an antenna 4, and an annular ceramic discharge chamber from outside to inside along the radial direction. 5 and inner magnetic coil group 6.

[0032] The outer magnetic shield 1 is a cylindrical structure with a bottom, its open end has an inwardly extending shoulder, and the bottom has an outer annular air supply port. In some embodiments, the outer magnetic shield 1 can be made of a soft iron core with a certain thickness, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com