Refrigerating control system capable of being remotely controlled

A technology of refrigeration control and remote control, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as economic loss, fresh food deterioration in cold storage, failure to detect in time, and achieve the effect of eliminating fresh food deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

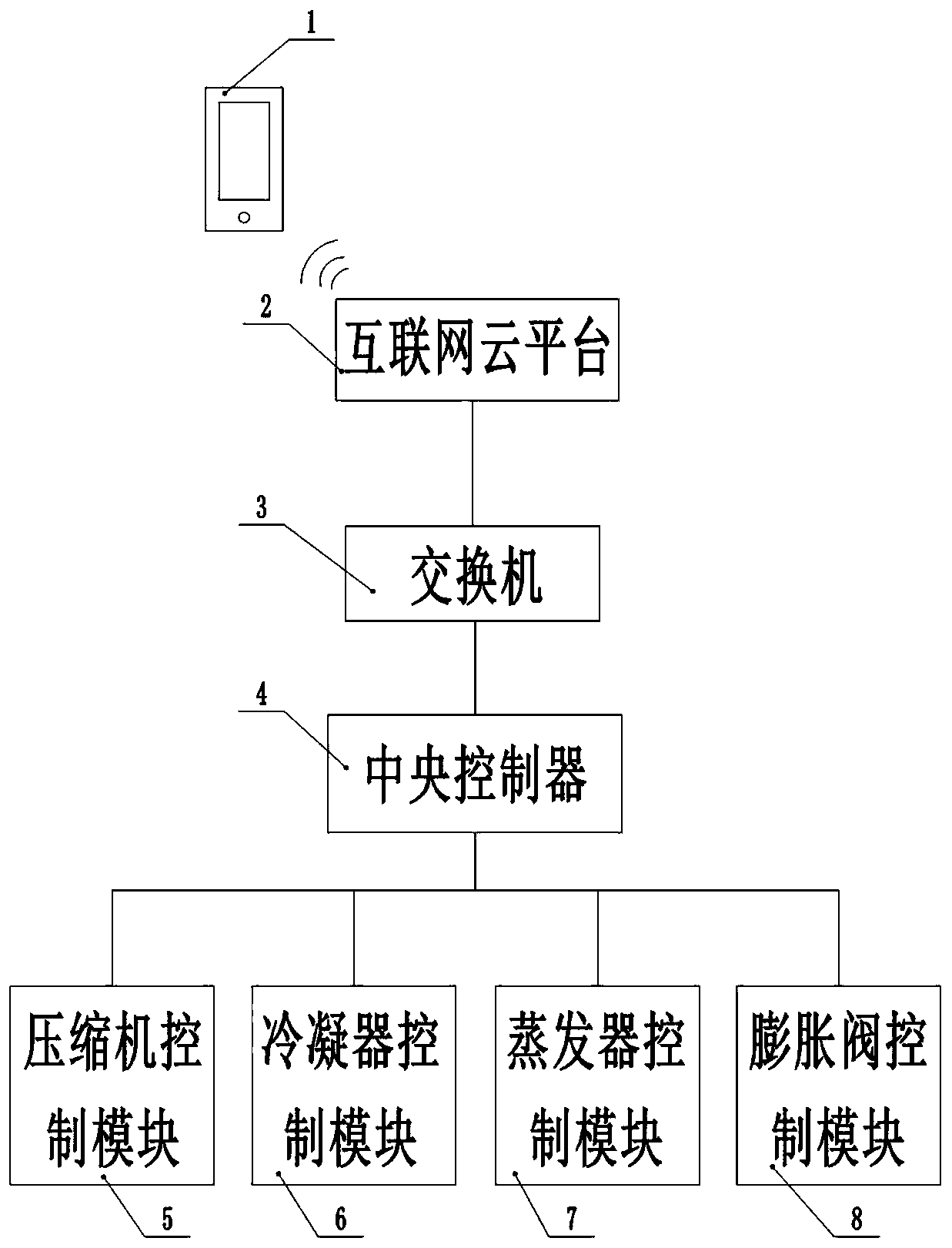

[0028] Such as figure 1As shown, this embodiment provides a remote-controllable refrigeration control system, including a compressor control module 5, a condenser control module 6, an evaporator control module 7, and an expansion valve control module 8, and also includes a control module capable of controlling the compressor 5. The central controller 4 of the condenser control module 6, the evaporator control module 7 and the expansion valve control module 8, the Internet cloud platform 2 and the mobile terminal 1, the central controller 4 is a local computer server, and the computer server is installed with the Compressor control module 5, condenser control module 6, evaporator control module 7 and expansion valve control module 8's collected data store local database and control software, central controller 4 and Internet cloud platform 2 through Intel network or Internet connection, the central controller 4 is provided with an experience database, which records the possible...

Embodiment 2

[0037] The working principle of this system is: a local database and control software for storing the collected data of the compressor control module 5, the condenser control module 6, the evaporator control module 7 and the expansion valve control module 8, the central controller 4 and the The Internet cloud platform 2 is connected through the Intel network or the Internet, and the central controller 4 is provided with an experience database, which records possible failures and solutions of the entire refrigeration system. When the compressor, condenser, evaporator and When the expansion valve fails, the compressor control module 5, the condenser control module 6, the evaporator control module 7 and the expansion valve control module 8 can respectively convert the sensor failure analog signals of the compressor, condenser, evaporator and expansion valve Convert the digital signal into a digital signal and transmit the digital signal to the central controller 4. The central con...

Embodiment 3

[0039] The basic structure of the refrigeration system is introduced:

[0040] The refrigeration system consists of 4 basic parts, namely compressor, condenser, throttling parts and evaporator. The four parts are connected in a certain order by copper tubes to form a closed system, and a certain amount of refrigerant is filled in the system.

[0041] Working principle: The compressor sucks the low-temperature and low-pressure Freon gas from the evaporator and compresses it into high-temperature and high-pressure Freon gas, then flows through the capillary tube of the thermal expansion valve, throttling into a low-temperature and low-pressure Freon gas-liquid two-phase object, and then The freon liquid in the evaporator absorbs heat from the indoor air and becomes a low-temperature and low-pressure freon gas, which is inhaled by the compressor again. After the indoor air passes through the evaporator, heat is released and the air temperature drops. Such compression, condensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com