Device and method for testing bonding strength of composite pipe under hot loading condition

A technology combining strength and composite pipes, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as safety hazards and production accidents, and achieve the effect of wide temperature control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

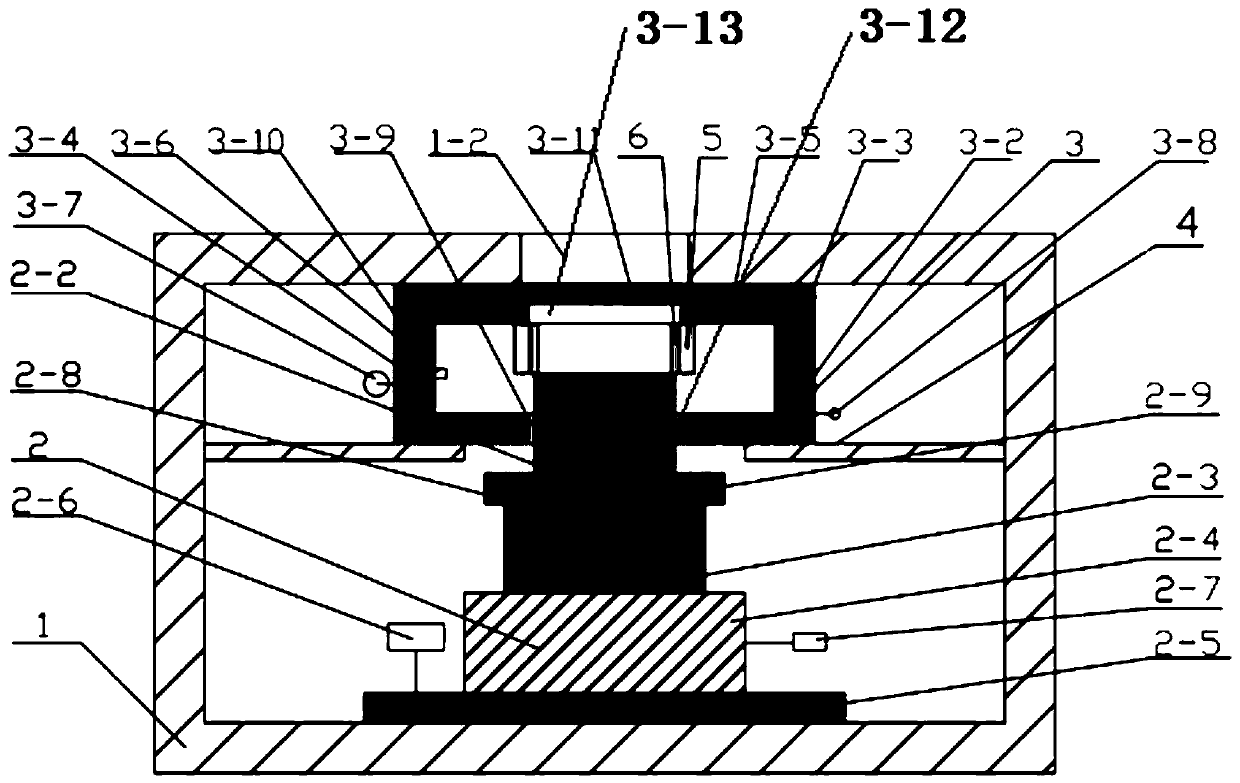

[0052] Example 1: Test the bonding strength of the bimetal composite pipe at 300°C

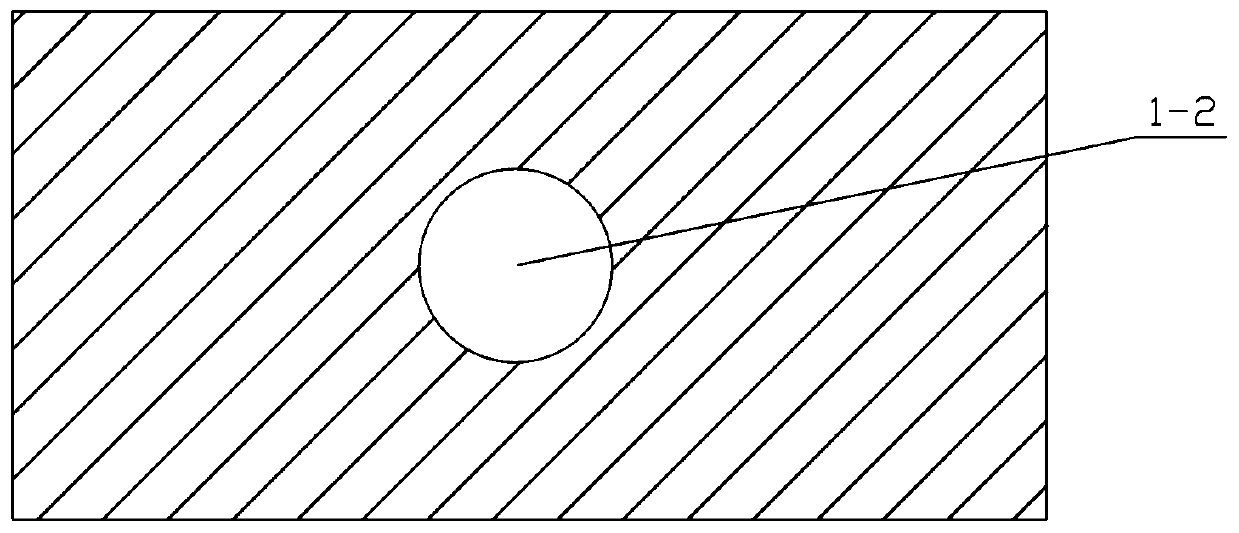

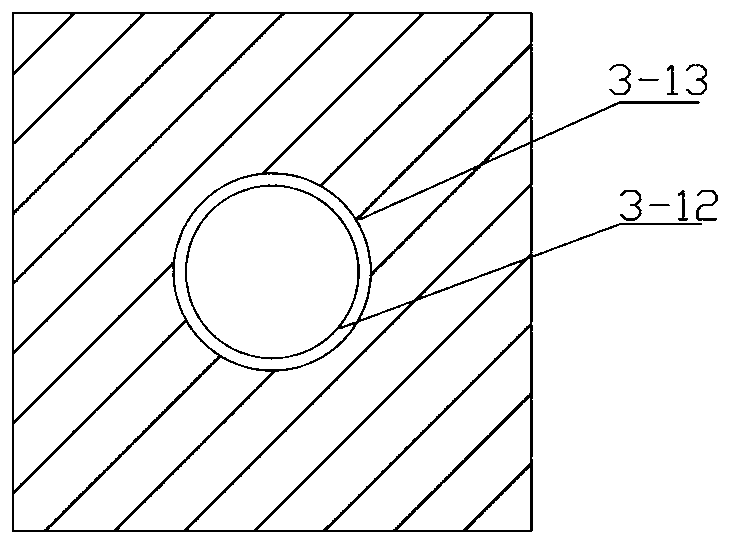

[0053] (1) Test pipe section preparation: cut 20mm long, 51mm carbon steel pipe combined with 3mm stainless steel pipe is a bimetal composite pipe, the inner diameter of the composite pipe is 56mm, and the diameter of the joint surface of the composite pipe is 62mm. (2) Selection of test accessories: Select a variable-diameter indenter with a diameter of 60mm; (3) Test assembly: Assemble the variable-diameter indenter with the indenter, and place a heat-insulating gasket in the middle; pass the variable-diameter indenter and the heating insulation box through the bottom Through-hole assembly; adjust the center of the test pipe section and place it on the variable-diameter indenter to ensure that the stainless steel layer falls evenly on the variable-diameter indenter; adjust the height of the heating insulation box so that the upper edge of the box body is flush with the upper end surface of ...

Embodiment 2

[0055] Example 2: Testing the bonding strength of metal-ceramic composite oil pipes at 500°C

[0056] (1) Test pipe section preparation: cut 20mm long, The cermet composite pipe with carbon steel pipe and 3mm cermet layer, the inner diameter of the composite pipe is 70mm, and the diameter of the joint surface of the composite pipe is 76mm. (2) Selection of test accessories: Select a variable-diameter indenter with a diameter of 75mm; (3) Test assembly: Assemble the variable-diameter indenter with the indenter, and place a heat-insulating gasket in the middle; pass the variable-diameter indenter and the heating insulation box through the bottom Through-hole assembly; adjust the center of the test pipe section and place it on the variable-diameter indenter to ensure that the ceramic layer falls evenly on the variable-diameter indenter; adjust the height of the heating insulation box so that the upper edge of the box body is flush with the upper end surface of the pipe section; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com