Topological optimization design method of self-supporting structure for additive manufacturing

A self-supporting structure and topology optimization technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as waste of raw materials and time costs, damage to the surface of workpieces, etc., to achieve saving consumables, shortening the manufacturing cycle, and high flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with embodiment the present invention is described in further detail:

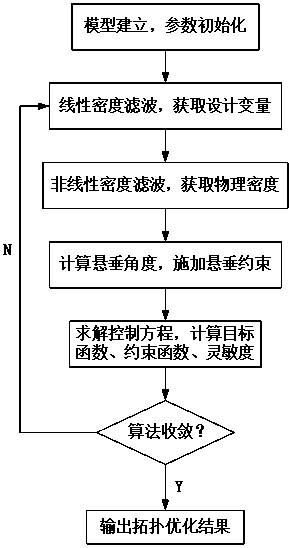

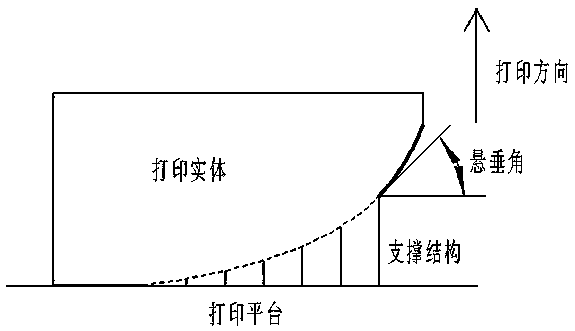

[0067] A topology optimization design method for self-supporting structures used in additive manufacturing, which calculates and constrains the overhang angle α through the "four-unit method", and combines the overhang angle constraints with the SIMP method to obtain a self-supporting overhang structure method . Such as figure 2 As shown, the overhang structure of the printed entity is overhanged by the overhang threshold angle α 0 Divided into two parts. The part of the thick solid line is that the overhang angle α is greater than or equal to the overhang threshold angle α 0 The overhanging structure of , no need to add auxiliary support when printing, realizes self-support; the dotted line part is that the overhang angle α is less than the overhang threshold angle α 0 The overhanging structure needs to add auxiliary support during printing to ensure successful printing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com