8-shaped traveling wave type linear ultrasonic motor and platform feeding device

A linear ultrasonic motor, 8-shaped technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of rare ultrasonic motor, low drive efficiency, and output direction Inconsistency and other problems, to achieve the effect of more synchronous output, convenient installation and fixing, and strong driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

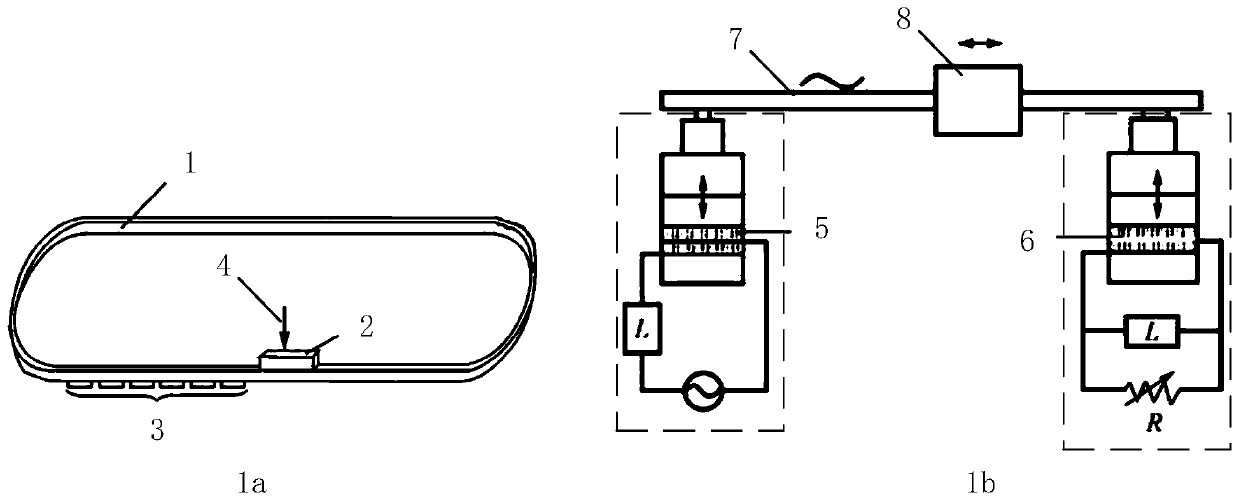

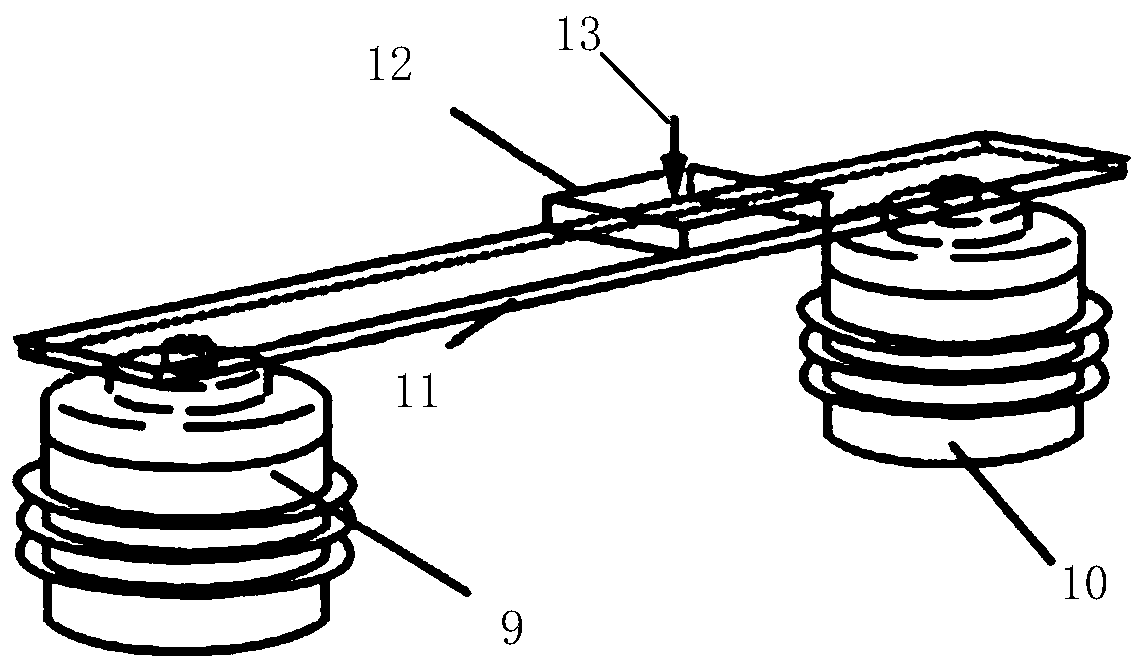

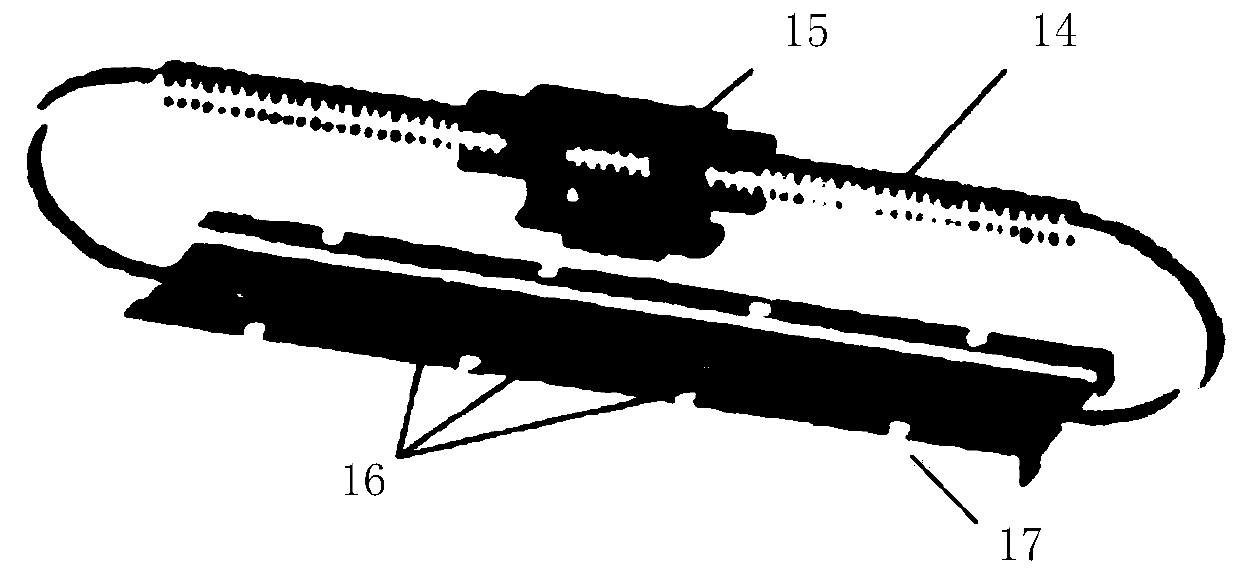

[0065] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0066] Such as Figure 7-Figure 16As shown, the characteristic components involved in the present invention include the following: 30 is the stator assembly, 301 is the stator elastic body, 302 is the 8-shaped piezoelectric ceramic sheet, 303 is the flexible printed board, 304a, 304b, 304c are friction materials, 3011 3012 is a straight line section, 3012 is a circular arc section, 3013 is a number of toothed structures on the surface of the straight line section, 3014 is a number of toothed structures on the surface of the circular arc section, 3015 is a flexible web, and 3016 is a counterweight structure (fixed installation structure) 3028a, 3028b are the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com