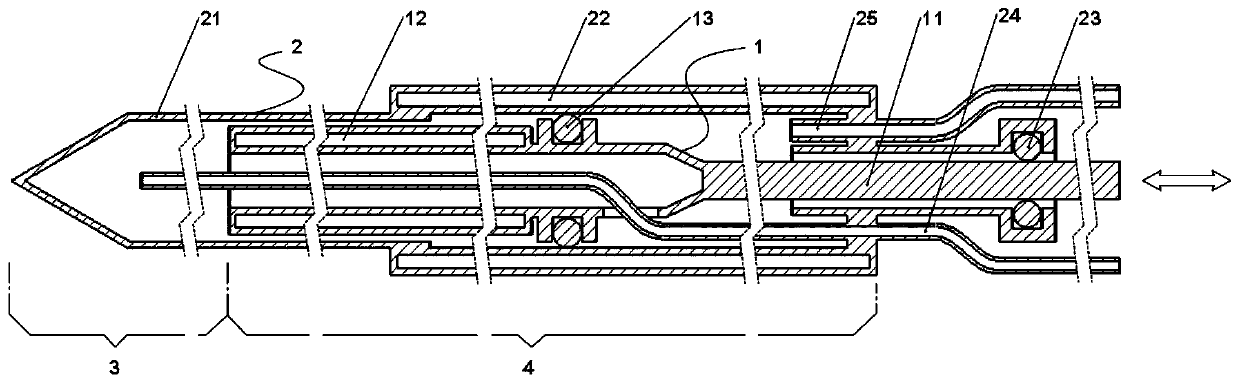

Cryoablation needle with adjustable target area

An ablation needle and targeting technology, which is applied in the field of cryoablation needles, can solve the problems of complicated treatment operations, easy injury and surrounding healthy tissues, and achieve the effects of smooth air return, avoiding cold loss, and preventing frostbite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

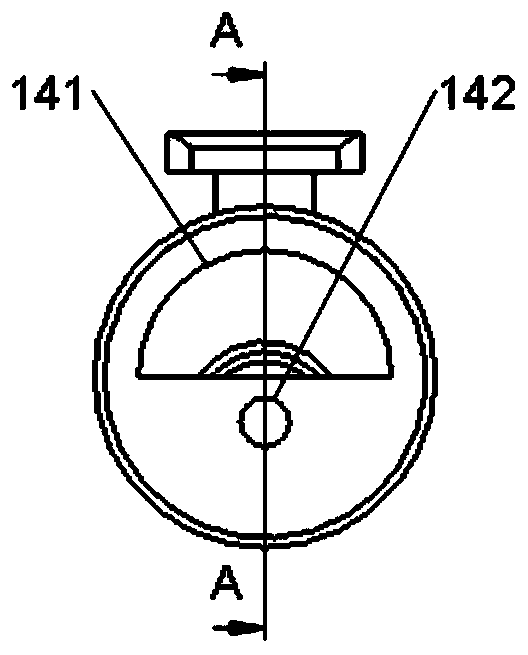

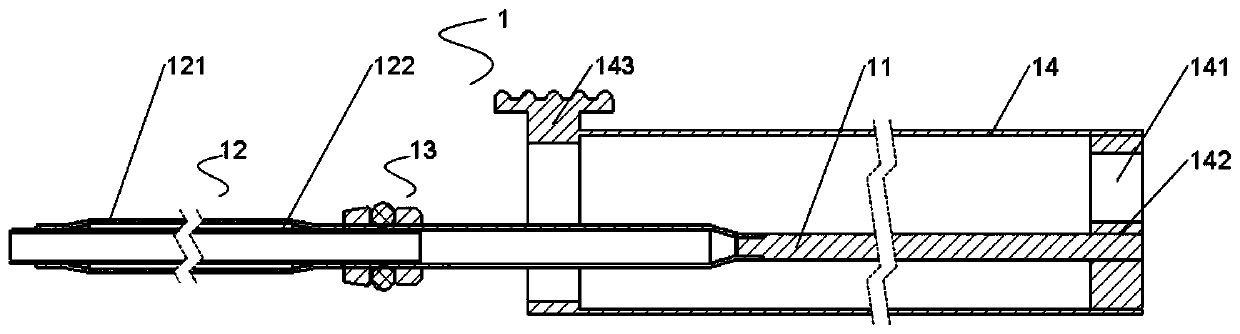

[0074] Please refer to image 3 , the tube wall of the front section heat insulation pipe 12 can be made of heat insulating material, also can adopt double-layer vacuum wall, the present invention does not make specific limitation, present embodiment preferably double-layer vacuum wall, namely described front section heat insulation pipe 12 comprises The front-section inner tube 122 and the front-section outer tube 121 form a vacuum interlayer between the front-section inner tube 122 and the front-section outer tube 121 .

[0075] As an embodiment, both ends of the front-section outer tube 121 are shrinked and vacuum-welded with the front-section inner tube 122 to form a permanent vacuum interlayer;

[0076] As another embodiment, both ends of the front-section inner tube 122 are flared and vacuum-welded with the front-section outer tube 121 to form a permanent vacuum interlayer;

[0077] As a third embodiment, the two ports of the front-section inner tube 122 are flush with ...

Embodiment 2

[0101] Please refer to Figure 15 and Figure 16 , when the return air temperature of the cryoablation needle is not too low, the air return pipe 25 can be overlaid on the air intake pipe 243, Figure 11 It is the rear structure of the adjustable targeting area 3 of this type of cryoablation needle, and the structure not shown in the figure is the same as Figure 9 , Figure 10 unanimous. The rear end of the rear section inner pipe 222 of this structure is in an open state, only the air intake pipe 243 is fixedly connected to the rear section inner pipe 222 and gets final product, the return air pipe 25 is enclosed within the rear portion of the handle 26, and the air intake pipe 243 is located at the return air pipe 25 internal. The rear end sealing assembly 23 of this structure is a rear end sealing ring assembly, and the rear end sealing ring assembly is fixed on the outside of the rear end of the rear heat insulation pipe 22, between the rear heat insulation pipe 22 an...

Embodiment 3

[0104] In order to monitor the working status of the cryoablation needle and the central temperature of the frozen area in real time, the cryoablation needle needs to have a real-time temperature measurement function inside the target area. like Figure 17 As shown, the temperature measuring wire 271 can be led out through the gap of the fin tube 242. The fixed part 22 of this solution also includes a wire assembly 27, and the wire assembly 27 includes a temperature measuring wire 271 and a wire lead-out tube 272. The temperature measuring wire 271 The temperature measuring point 2711 is placed at the front end of the J-T groove 241, and the temperature measuring line 271 passes through the inner tube 122 of the front section, the return air groove 1331, and the gap between the finned tube 242 (the finned tube 242 is wound on the core with a certain pitch. On the shaft 11, the temperature measuring line 271 does not penetrate into the tube of the finned tube 242, but passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com