Device and method for polishing and coating arch ribs of concrete-filled steel tube arch bridge

A technology for concrete-filled steel tubes and painting, which is applied in grinding/polishing safety devices, jetting devices, grinding machines, etc., and can solve the problems of limited construction measures, difficult maintenance and construction, and harsh construction time requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

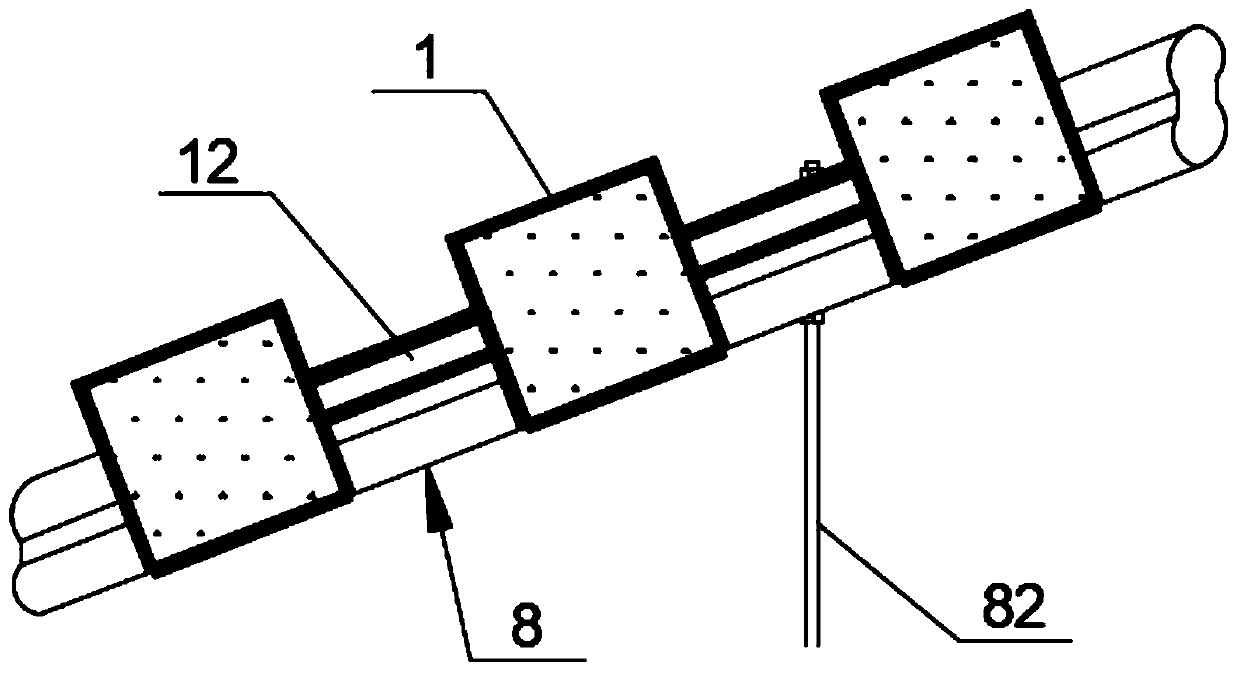

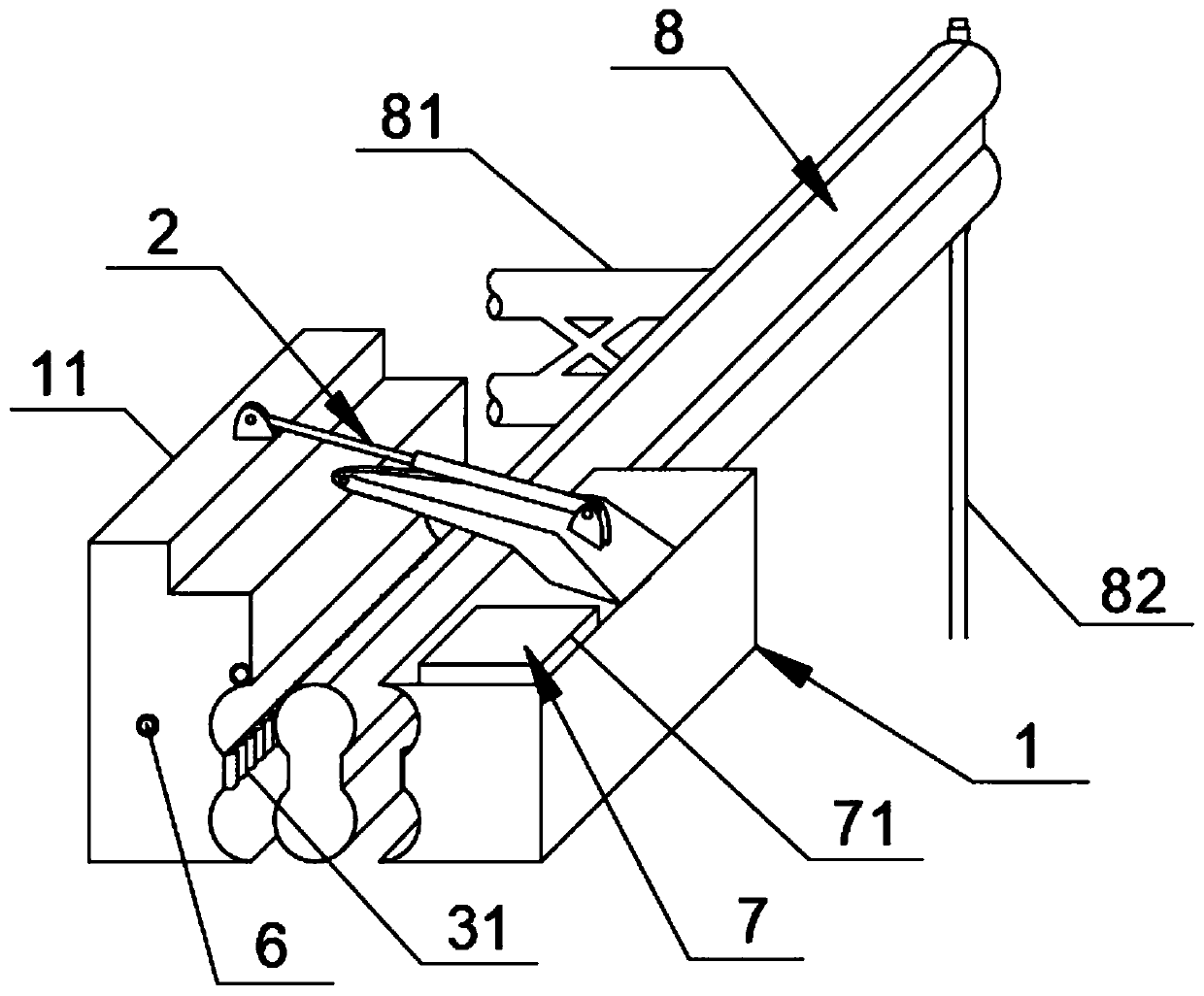

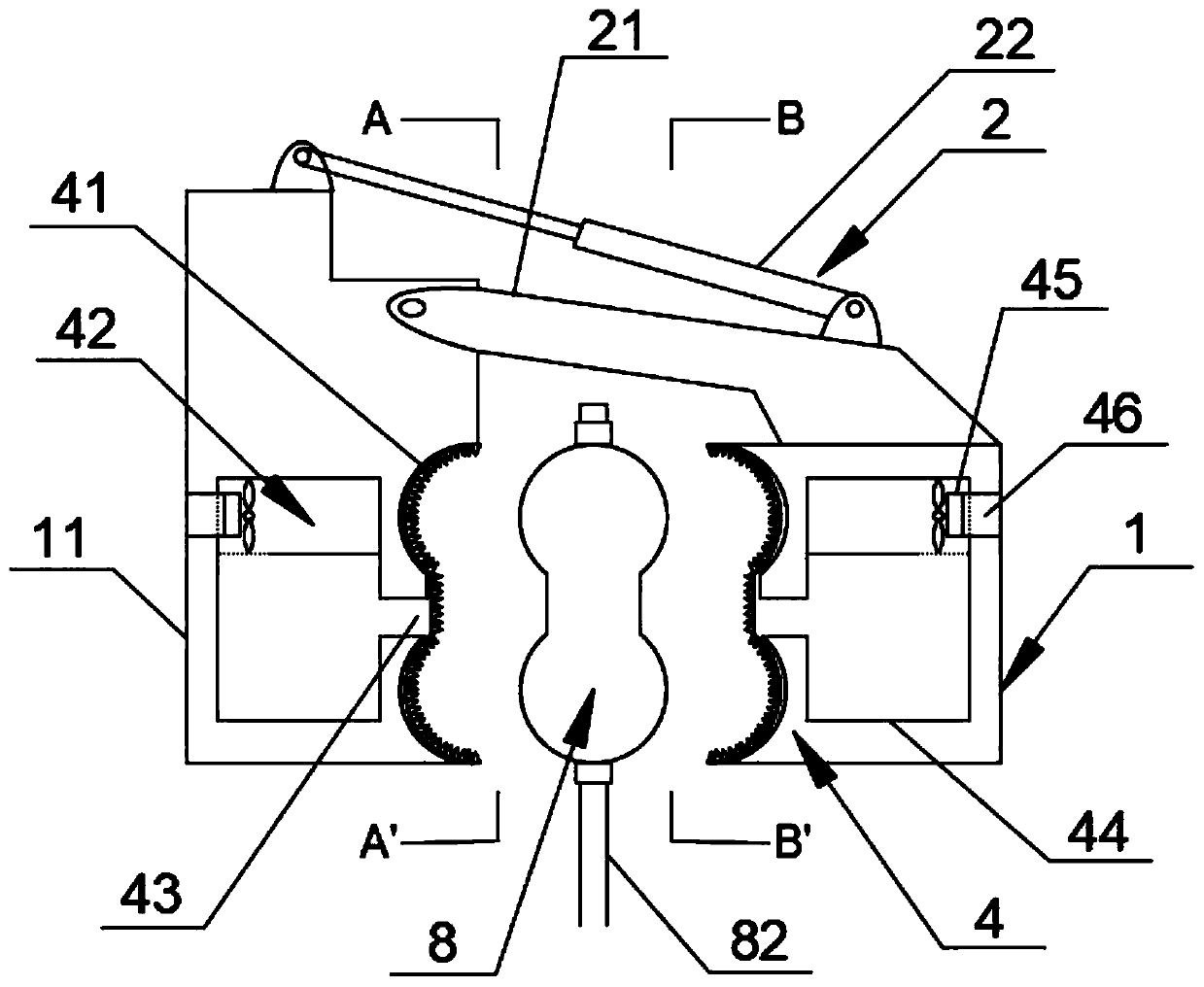

[0035] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a grinding and coating device for the arch rib of a steel tube concrete arch bridge. The arch rib 8 is provided with a cross brace 81 and a suspender 82. The grinding and coating device includes a clamping and fixing assembly 1, a driving assembly 2. Walking assembly 3, two derusting and polishing assemblies 4 and two anti-corrosion coating assemblies 5, clamping and fixing assembly 1 includes at least two pairs of grippers 11 and at least one connecting rod 12 arranged at intervals, each pair of grippers 11 is provided with the accommodating space that matches with arch rib 8, and connecting rod 12 connects the adjacent gripper 11 of the same side, and driving assembly 2 connects two grippers 11 in the same pair, and driving assembly 2 is used for driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com