Method for manufacturing flute

A production method and technology for bamboo materials, which are applied in the fields of manufacturing tools, reed/straw treatment, instruments, etc., can solve the problems of difficult to spread and spread, and achieve the effect of easy spread and promotion, enhanced toughness, durability and aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

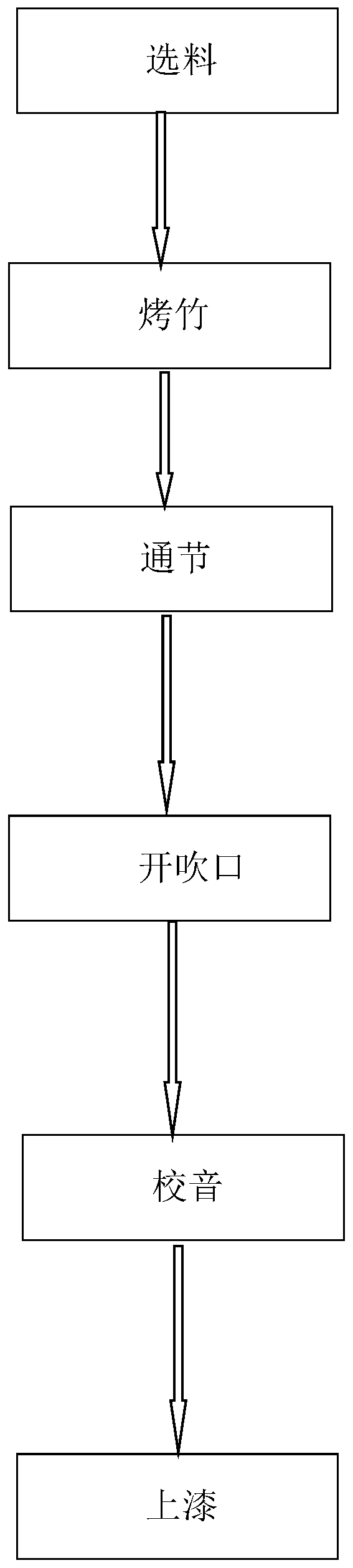

[0029] see figure 1 . A method for making an 8-hole flute, comprising the steps of:

[0030] (1) material selection;

[0031] Dongxiao is selected from the 3-5 year old purple bamboo grown on the slopes of Huangshan, Jiangxi, Yunnan and other places in China. - 3 years of standby, the environment of the shade room is kept at room temperature 23-25 ℃, humidity 60-80% RH;

[0032] (2) roasted bamboo;

[0033] Take out the bamboo material after drying in the shade, first heat and bake one end of the bamboo material on the gas stove, the heating temperature is 1300-1400 ℃, and continuously rotate the bamboo material during baking, until the surface of the bamboo material is oily and accompanied by hot air When it emerges, take out the bamboo material and pry straight the place where the bamboo material has a bend on the prying bamboo board, and repeat the heating and prying step until the bamboo material is aligned (visual alignment is enough, straightness ≤ 5mm); then reve...

Embodiment 2

[0047] A method for making a flute, comprising the steps of:

[0048] (1) material selection;

[0049]Choose 3-5-year-old bitter bamboo grown on hillsides in Jiangxi and other places in China, with a wall thickness of 3.5-4mm and an outer diameter of 21-29mm. The middle section of the bamboo is cut to one meter. The temperature in the shade room is 21-25°C, and the humidity is 60-80%RH; 3 years reserve;

[0050] (2) roasted bamboo;

[0051] Take out the bamboo material that has been dried in the shade, first heat and bake one end of the bamboo material on the electric stove, the heating temperature is 1800-2000 ℃, and rotate the bamboo material continuously during baking, until the surface of the bamboo material is oily and accompanied by hot air. Take out the bent part of the bamboo material on the prying bamboo board and pry it straight, repeat the heating and prying step until the bamboo material is aligned (visual alignment is enough, straightness ≤ 5mm) ; Then reverse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com