A paper tube drying intermittent swing conveying mechanism

A technology of conveying mechanism and paper tube, which is applied to conveyor objects, transportation and packaging, cardboard wound objects, etc., can solve the problems of uneven drying and long service life, and achieve smooth operation, long service life, and improved drying. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

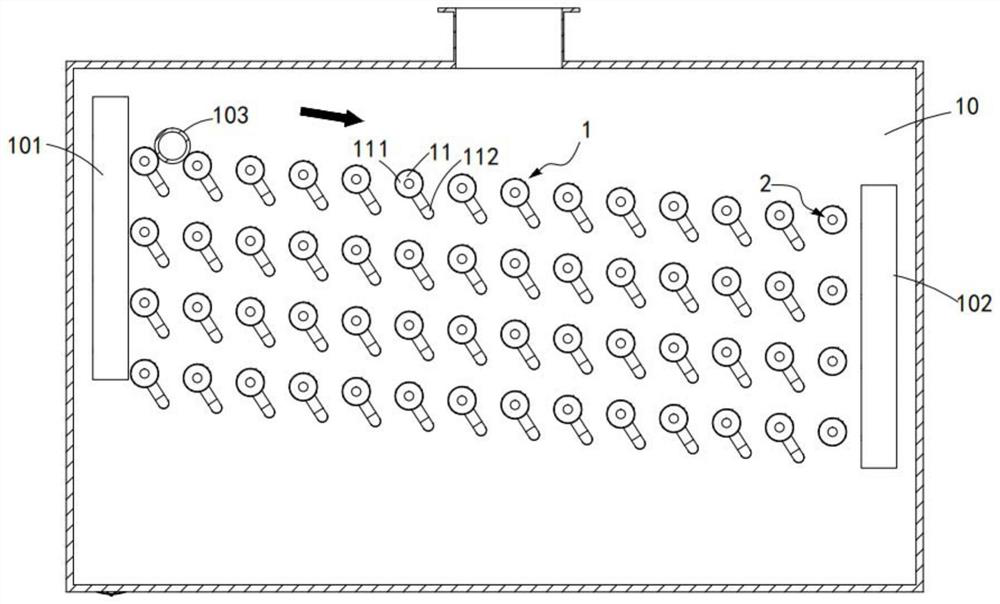

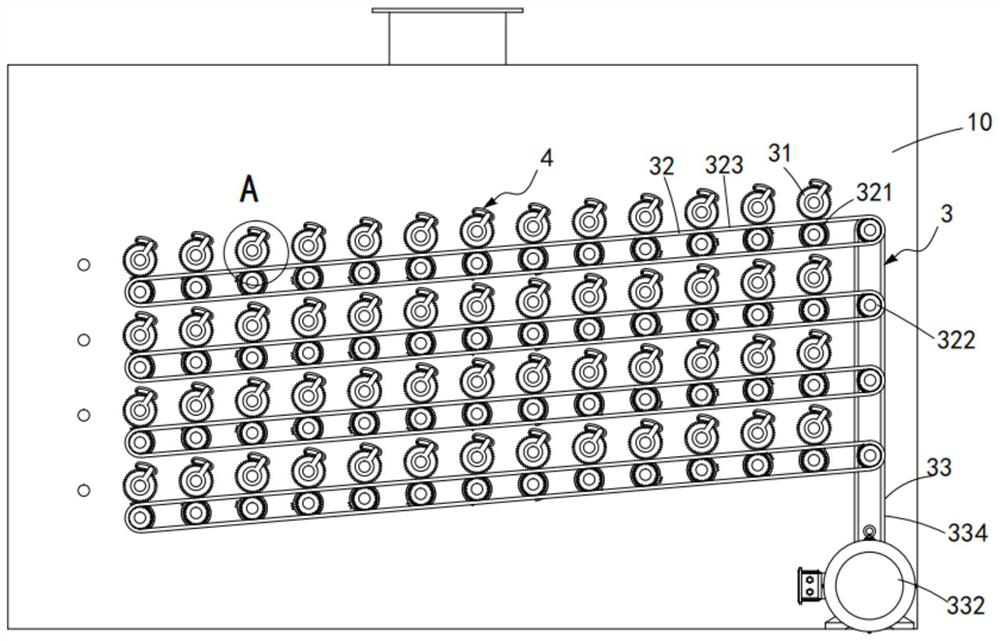

[0052] like Figure 1 to Figure 3 As shown, a paper tube drying intermittent swing conveying mechanism, including:

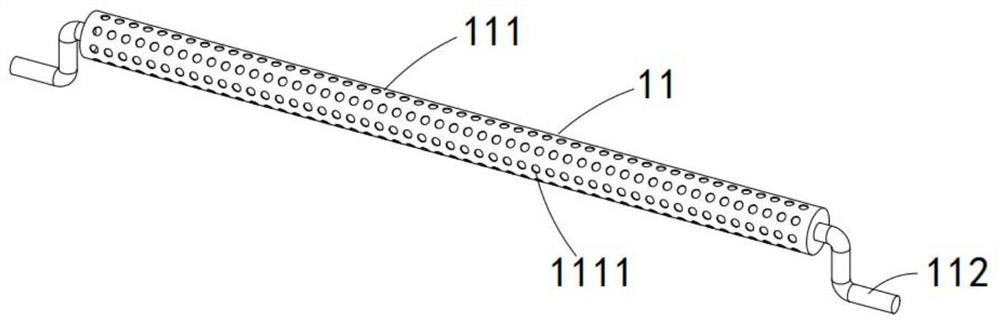

[0053] Conveyor roller group 1, several conveyer roller groups 1 are arranged obliquely along the drying and feeding direction of the paper cylinder in the drying room, the conveyer roller groups 1 are arranged in parallel with each other, and the conveyer roller groups 1 all include Several conveying rollers 11 equidistantly arranged, the two ends of the conveying roller 11 are arranged on the side wall of the drying room in rotation, it is arranged in a few characters, and it includes a horizontally arranged roller portion 111 and is arranged on both sides of the roller portion 111 The rotating part 112, the rotating part 112 is arranged in a zigzag shape, and its rotation is arranged on the side wall of the drying room;

[0054] Fixed roller 2, described fixed roller 2 and described conveying roller group 1 are arranged one by one, and it is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com