Intelligent processing setting production equipment for corrugated paper cores

A technology of intelligent processing and production equipment, applied in the direction of mechanical processing/deformation, etc., can solve the problems of reduced sound insulation and shock absorption capacity of corrugated cardboard, thickness reduction, etc., to achieve the effects of corrugated compactness, improved production efficiency, and saved horizontal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

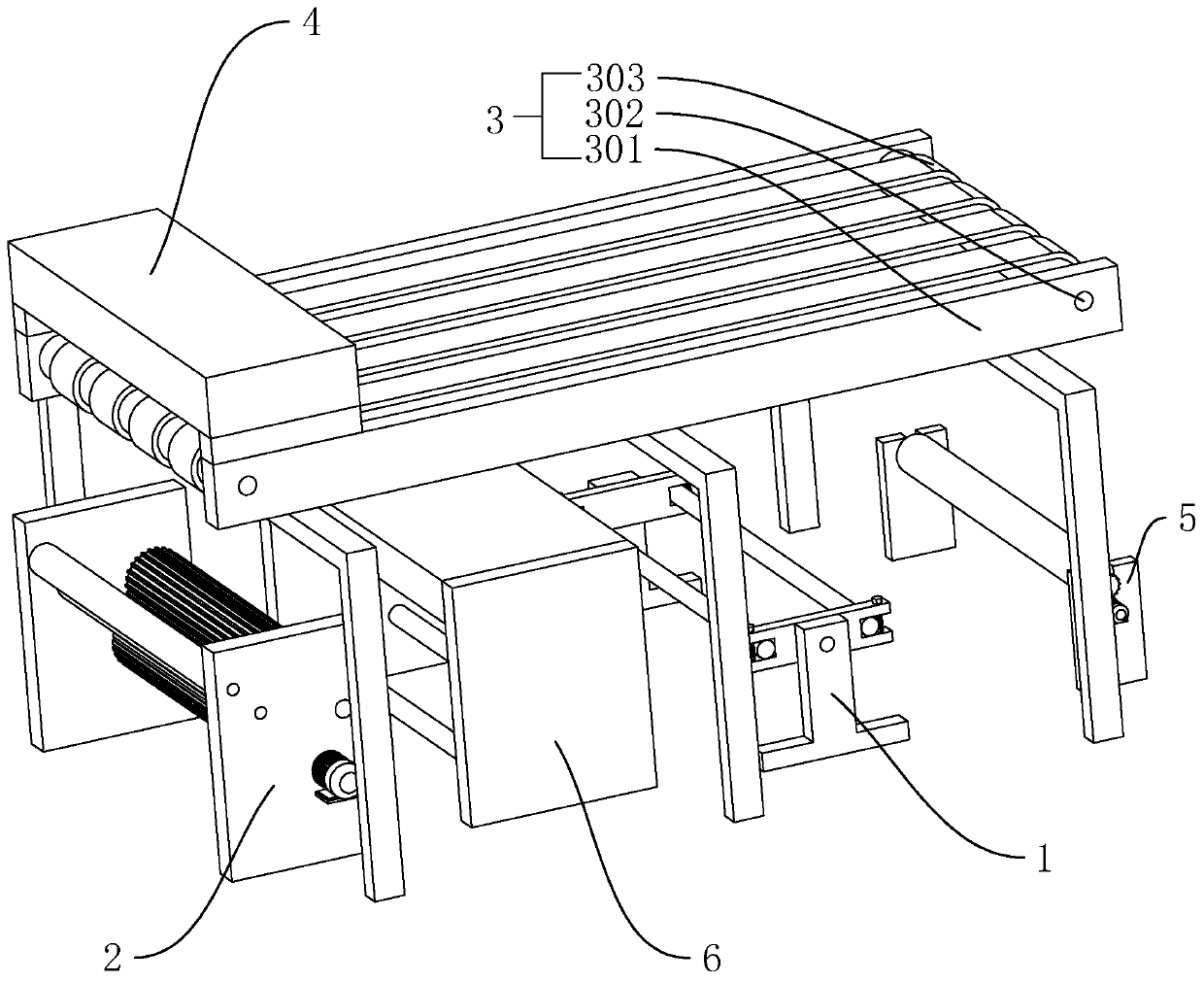

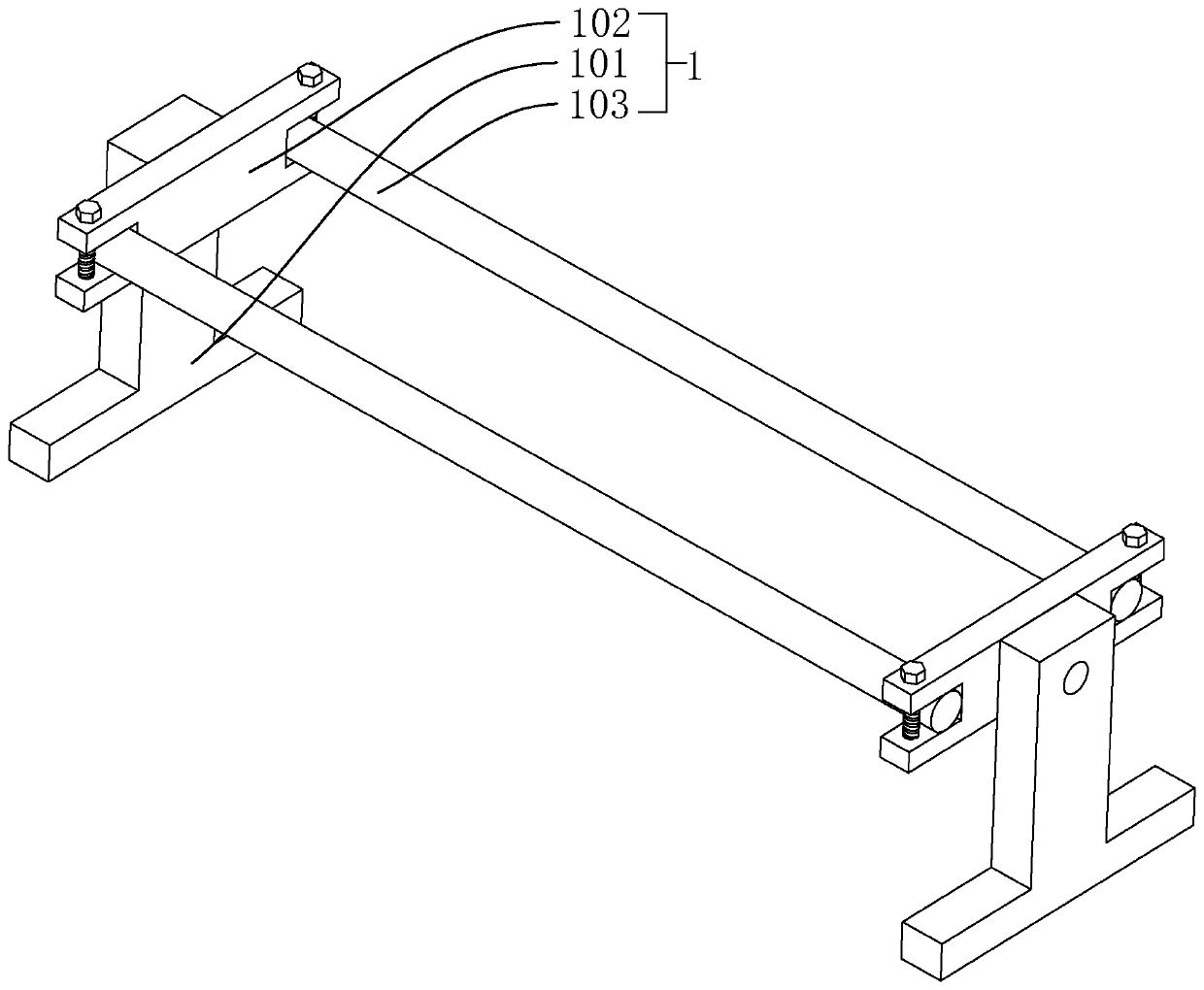

[0040] refer to figure 1 , is a corrugated paper core intelligent processing and shaping production equipment disclosed by the present invention, comprising an uncoiling mechanism 1, a corrugating mechanism 2 placed on one side of the uncoiling mechanism 1, a conveying mechanism 3 erected above the uncoiling mechanism 1, and a conveying mechanism 3 installed Dryer 4 on the top and rewinding mechanism 5 placed on the side of uncoiling mechanism 1 away from corrugating mechanism 2. The reel base paper is uncoiled from uncoiling mechanism 1, enters corrugating mechanism 2 and is pressed into corrugated core, and the corrugated core enters the conveying mechanism 3 for conveying, during which the dryer 4 shapes the pressed corrugated paper core, and finally the corrugated paper core leaves from the conveying mechanism 3 and enters the winding mechanism 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com