Method for pre-treating Fischer-Tropsch synthesis wastewater through catalytic ozone oxidation

A technology for Fischer-Tropsch synthesis of wastewater and ozone oxidation, which is applied in oxidation water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. Reduce COD, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for catalytic ozonation pretreatment of Fischer-Tropsch synthesis wastewater, comprising the steps of:

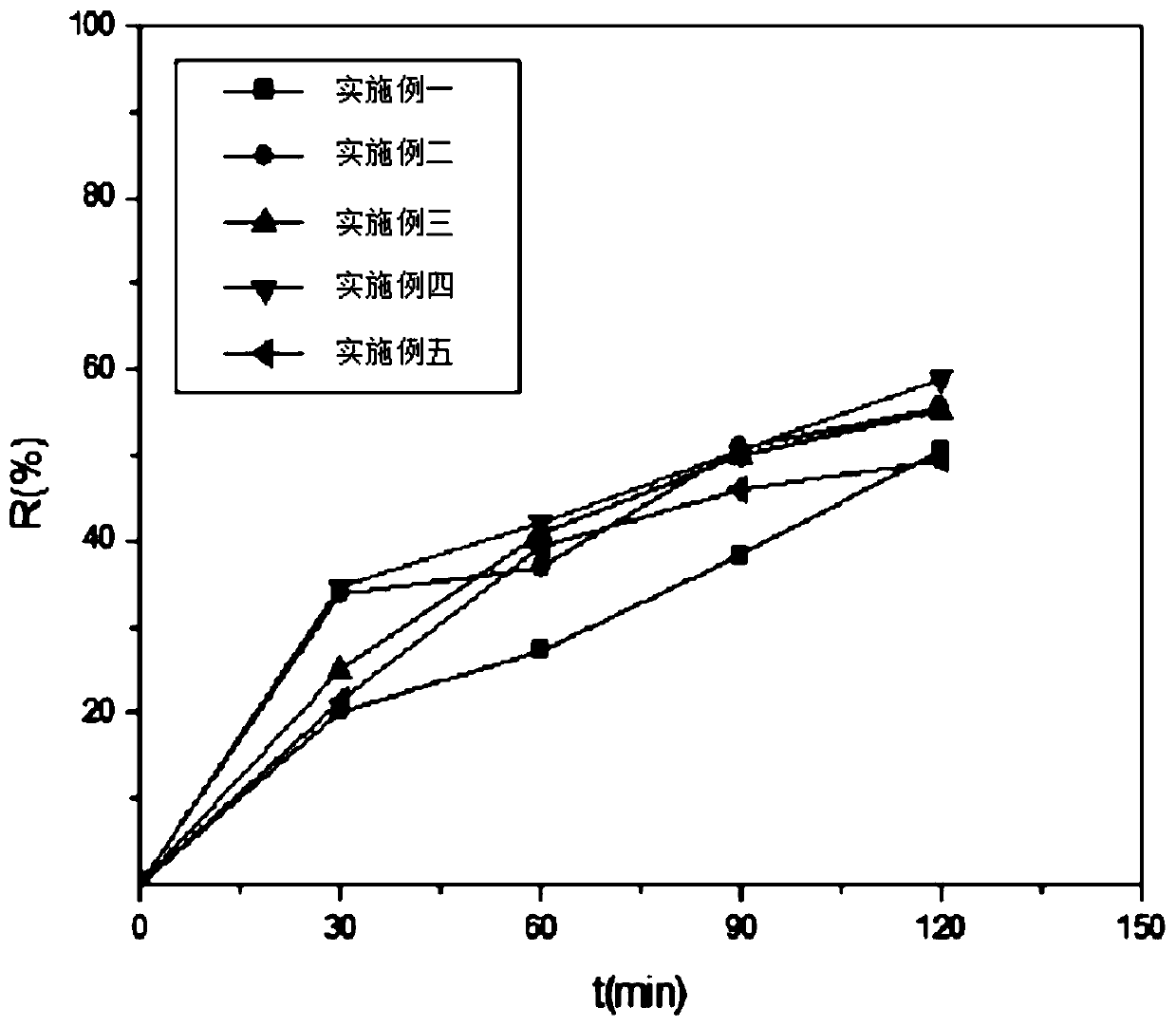

[0032] Take 100mL of Fischer-Tropsch synthetic wastewater with a COD concentration of 10000mg / L, put it into a reaction device with a capacity of 250ml, and weigh the powdered MnO 2 Catalyst 0.1g is put into reaction device, and reaction device access ozone output is the ozone generator of 10g / h, quantitatively feeds ozone in reaction device. Samples were taken at 30 min, 60 min, 90 min, and 120 min of reaction, and the samples were filtered through needle filters to obtain processed samples. The COD concentration of the treated sample was measured according to the potassium dichromate titration method (GB11914-89), and finally the COD removal efficiency of the Fischer-Tropsch synthesis wastewater was calculated. The result is as figure 1 shown.

Embodiment 2

[0034] A method for catalytic ozonation pretreatment of Fischer-Tropsch synthesis wastewater, comprising the steps of:

[0035] Take 100mL of Fischer-Tropsch synthetic wastewater with a COD concentration of 10000mg / L, put it into a reaction device with a capacity of 250ml, and weigh the powdered MnO 2 Catalyst 0.2g is put into reaction device, and reaction device access ozone output is the ozone generator of 10g / h, quantitatively feeds ozone in reaction device. Samples were taken at 30 min, 60 min, 90 min, and 120 min of reaction, and the samples were filtered through needle filters to obtain processed samples. The COD concentration of the treated sample was measured according to the potassium dichromate titration method (GB11914-89), and finally the COD removal efficiency of the Fischer-Tropsch synthesis wastewater was calculated. The result is as figure 1 shown.

Embodiment 3

[0037] A method for catalytic ozonation pretreatment of Fischer-Tropsch synthesis wastewater, comprising the steps of:

[0038] Take 100mL of Fischer-Tropsch synthetic wastewater with a COD concentration of 10000mg / L, put it into a reaction device with a capacity of 250ml, and weigh the powdered MnO 2 Catalyst 0.3g is put into reaction device, and reaction device access ozone output is the ozone generator of 10g / h, quantitatively feeds ozone in reaction device. Samples were taken at 30 min, 60 min, 90 min, and 120 min of reaction, and the samples were filtered through needle filters to obtain processed samples. The COD concentration of the treated sample was measured according to the potassium dichromate titration method (GB11914-89), and finally the COD removal efficiency of the Fischer-Tropsch synthesis wastewater was calculated. The result is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com