Continuous alcoholysis and continuous transesterification recovery method of waste polyester material

A recycling method and polyester material technology, applied in plastic recycling, recycling technology, chemical instruments and methods, etc., can solve problems such as long alcoholysis time, uneven quality, multi-configuration concentration equipment, etc., to avoid side reactions, Short alcoholysis time and stable product quality

Active Publication Date: 2019-11-29

AVANTGARDE SHANGHAI ENVIRONMENTAL TECH CO LTD

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] For this reason, it is necessary to provide a continuous alcoholysis and continuous transesterification recovery method for waste polyester materials, so as to solve the problems of long alcoholysis time and uneven quality caused by intermittent reactions in the background technology, and the quality of alcoholyzed products and transesterified products is not good. Stable, need to configure more enrichment equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0106] In embodiment 2, only the raw material is changed into waste polyester film, and processed into pieces of 5-10mm×5-10mm, other steps are all the same.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

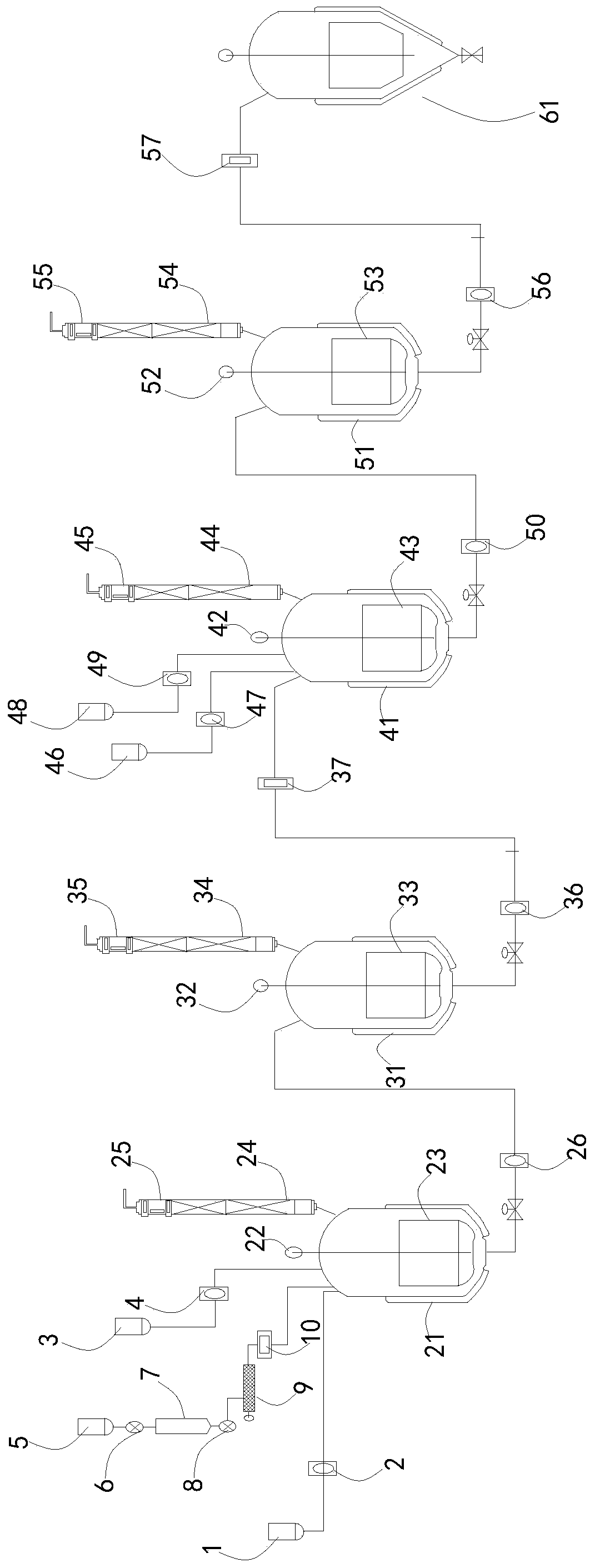

The invention relates to a recovery method of a waste polyester material, particularly to a method for preparing dimethyl terephthalate (DMT) by chemically recovering waste polyester, and belongs to the technical field of waste polyester recycling. According to the method, a process comprising continuous feeding, continuous alcoholysis and continuous transesterification is adopted, such that materials are subjected to homogeneous alcoholysis in a molten state so as to achieve a short required alcoholysis time; more than two alcoholysis kettles are connected in series to carry out continuous alcoholysis, such that the alcoholysis product has stable quality; and the alcoholysis product continuously enters a transesterification kettle, and is subjected to a continuous transesterification reaction, and the EG generated by the transesterification reaction can be recycled in the alcoholysis step, such that the generation of side reactions and the unstable transesterification product qualityare avoided, and the purity and the yield of the waste polyester recovery product are greatly improved.

Description

technical field [0001] The invention relates to a method and device for recycling waste polyester materials, in particular to a method and device for preparing dimethyl terephthalate (DMT) through chemical recovery of waste polyester, belonging to the technical field of waste polyester recycling . Background technique [0002] Polyester (polyethylene terephthalate, PET) is the synthetic fiber material with the largest output, which is widely used in fibers, textile fabrics, clothing, polyester bottles, films, sheets and other products. Based on the enhancement of environmental awareness, resource conservation and sustainability needs, how to deal with the scraps produced in the manufacture of polyester products and the waste of polyester products after use has become an urgent problem to be solved. The recycling of waste polyester has become a green textile development. direction. [0003] At present, the recycling methods of waste polyester mainly include physical recycli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C67/03C07C69/82

CPCC07C67/03C07C69/82C08J11/24C08J2367/02C08J11/16Y02W30/62C07C67/30B01J20/20C08J11/22C08J2367/00

Inventor 方华玉朱恩斌李天源陈锦程吴建通陈建华林胜尧王国德

Owner AVANTGARDE SHANGHAI ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com