Full-automatic numerical control galvanizing machine

A fully automatic, walking mechanism technology, applied in the direction of hot-dip plating process, coating, metal material coating process, etc., can solve the problems of waste, operator injury, high power consumption of equipment operation, etc., to reduce the scrap rate, Reduce damage, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

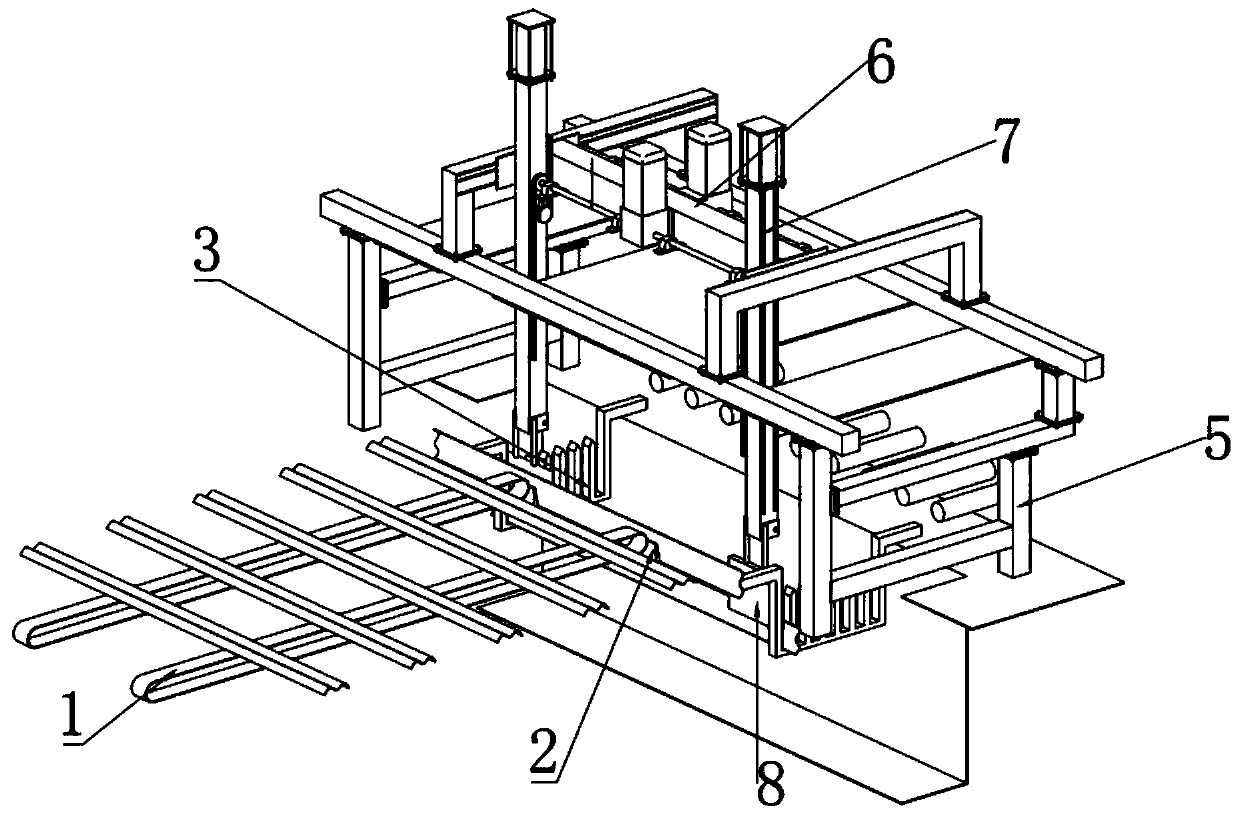

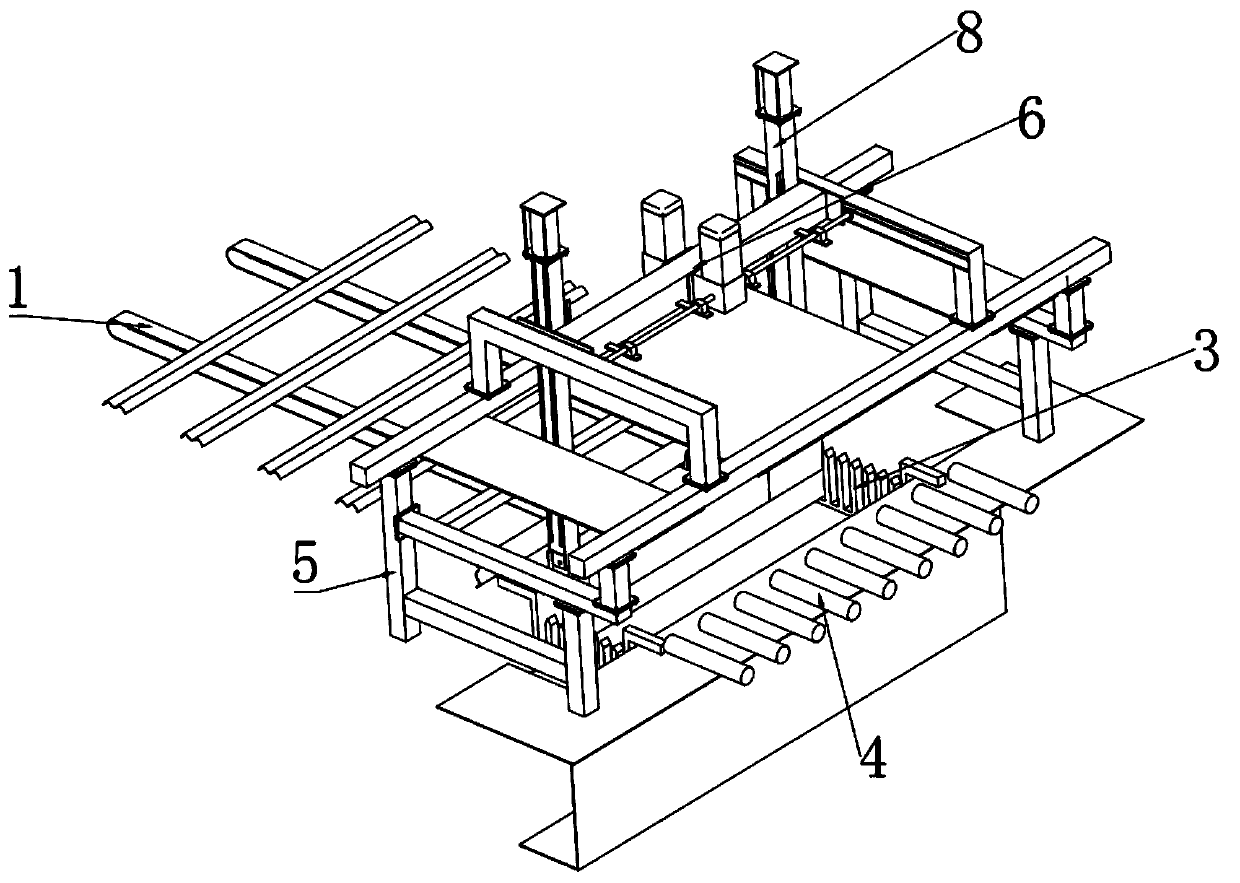

[0016] The full-automatic numerically controlled galvanizing machine of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] combined with Figure 1-3 , a fully automatic numerical control galvanizing machine, including a conveyor chain 1, a pre-stored material support 2 fixedly connected to one end of the conveyor chain 1, a material discharge support 3, a traveling mechanism, a grabbing mechanism, and a roller conveying mechanism 4; the traveling mechanism is set on the workpiece The conveyor chain 1 is provided with the side of the pre-stored material support 2, the roller conveying mechanism 4 is arranged on the side of the traveling mechanism away from the workpiece conveying chain 1, and the described discharging support 3 is arranged at the bottom of the traveling mechanism and close to the pre-stored material support 2.

[0018] Described walking mechanism comprises support 5, the X-axis left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com