Durable hydraulic cylinder

A hydraulic cylinder and durable technology, applied in the field of hydraulic cylinders, can solve the problems of broken connection between the cylinder head and the front rod, low thread connection strength, etc., and achieve the effects of long service life, not easy to break, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

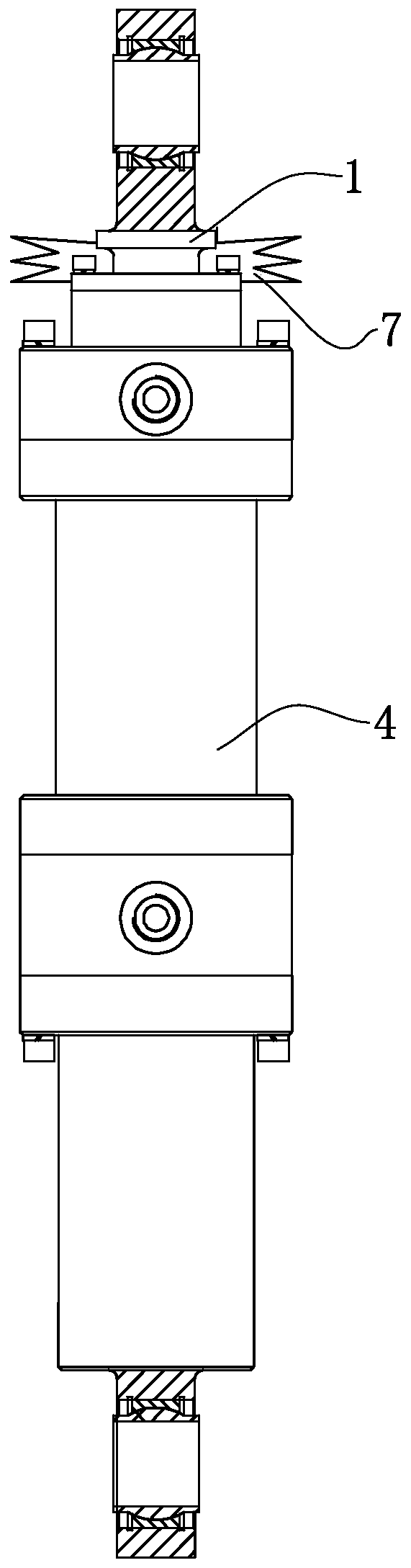

[0042] refer to figure 1 , discloses a durable hydraulic cylinder for the present invention, comprising a casing 4, one end of the casing 4 is slidably connected with a piston rod 1 moving along its axial direction, and the end of the casing 4 facing away from the piston rod 1 is welded with a cylinder tail earring 5.

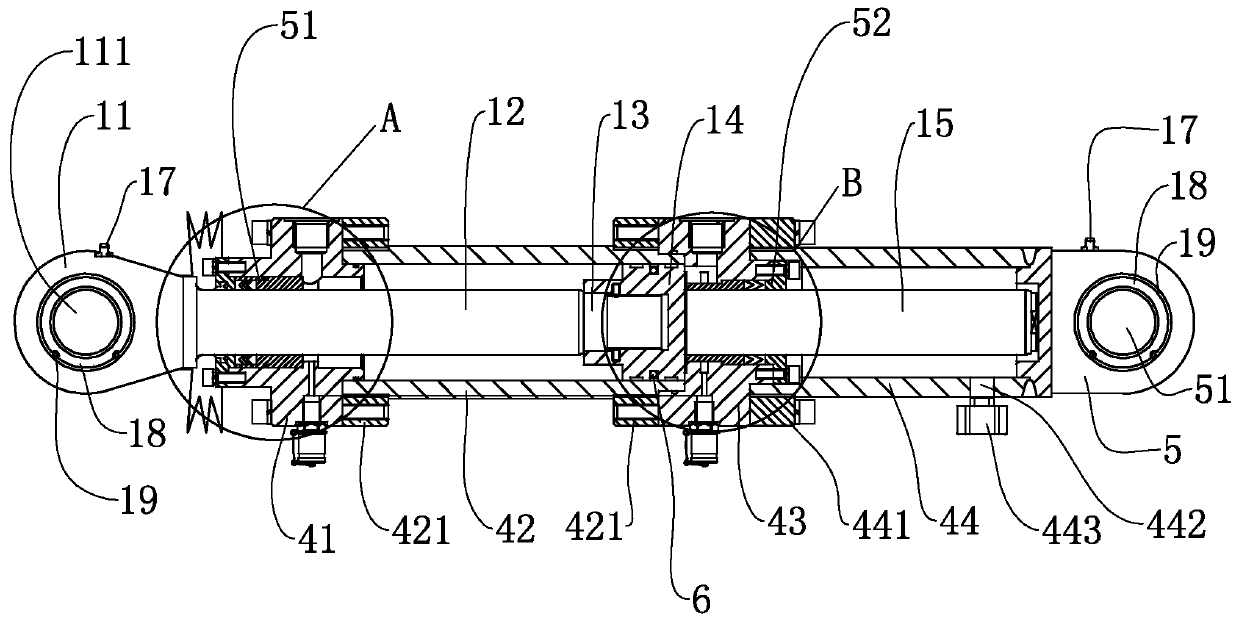

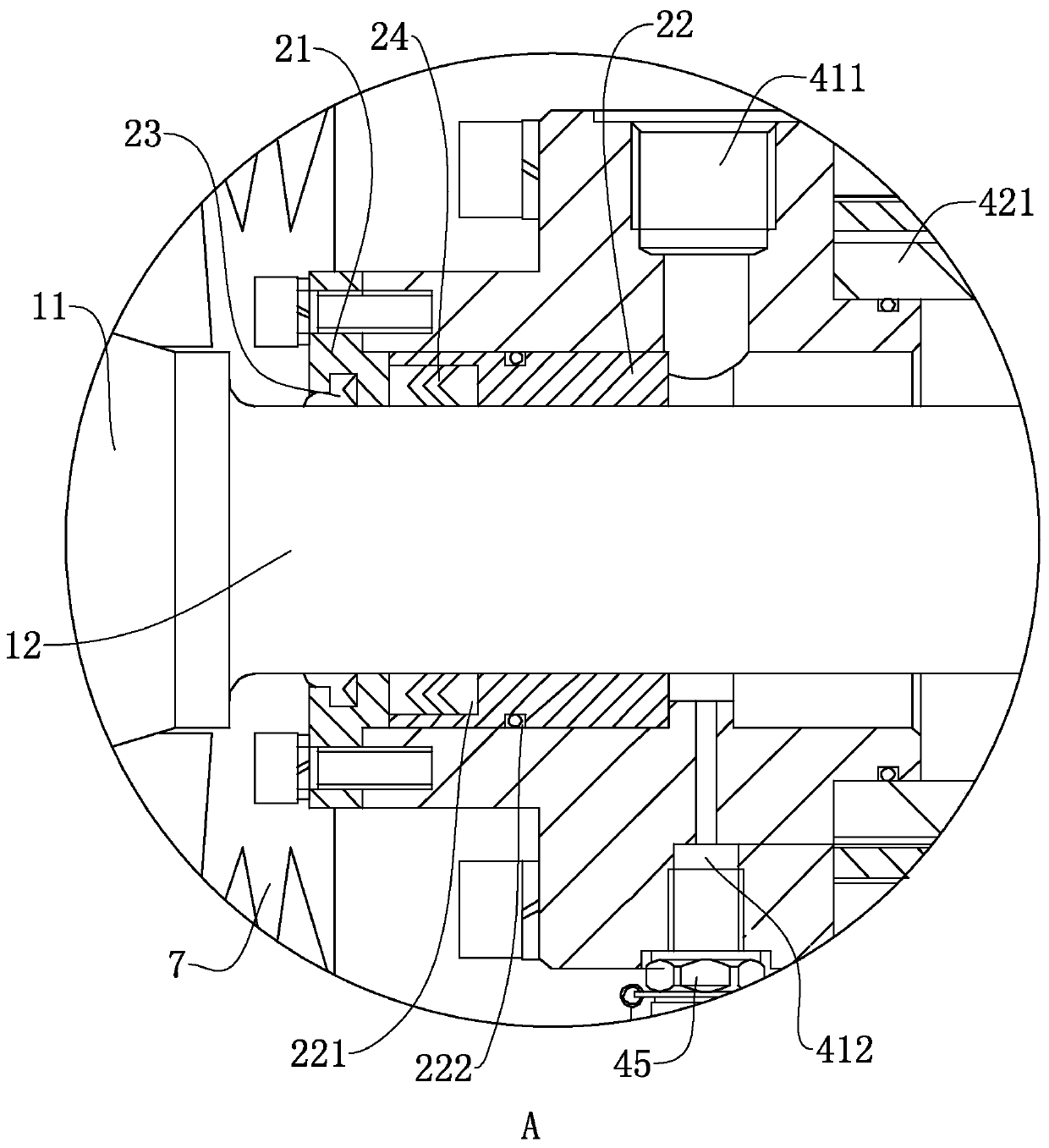

[0043] refer to figure 2 and image 3 , the shell 4 includes a cylinder head 41, the cylinder head 41 is detachably connected with a cylinder barrel 42, the cylinder barrel 42 is detachably connected with a cylinder tail 43, and the cylinder tail 43 is detachably connected with a cylinder body 44; the cylinder head 41, the cylinder barrel 42. Cylinder tail 43 and cylinder body 44 are circular tubes with overlapping centerlines. Cylinder head 41, cylinder barrel 42, cylinder tail 43 and cylinder body 44 are detachably connected in turn.

[0044] refer to figure 2 , image 3 and Figure 6 , the structure of the cylinder head 41 is a circular tube, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com