Heating network hydraulic balance adjusting method and system based on heating station resistance characteristics

A technology of hydraulic balance and resistance characteristics, applied in the field of heating network hydraulic balance control method and system, can solve the problems that are not conducive to precise control of heating network, can not achieve better control effect, frequent fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

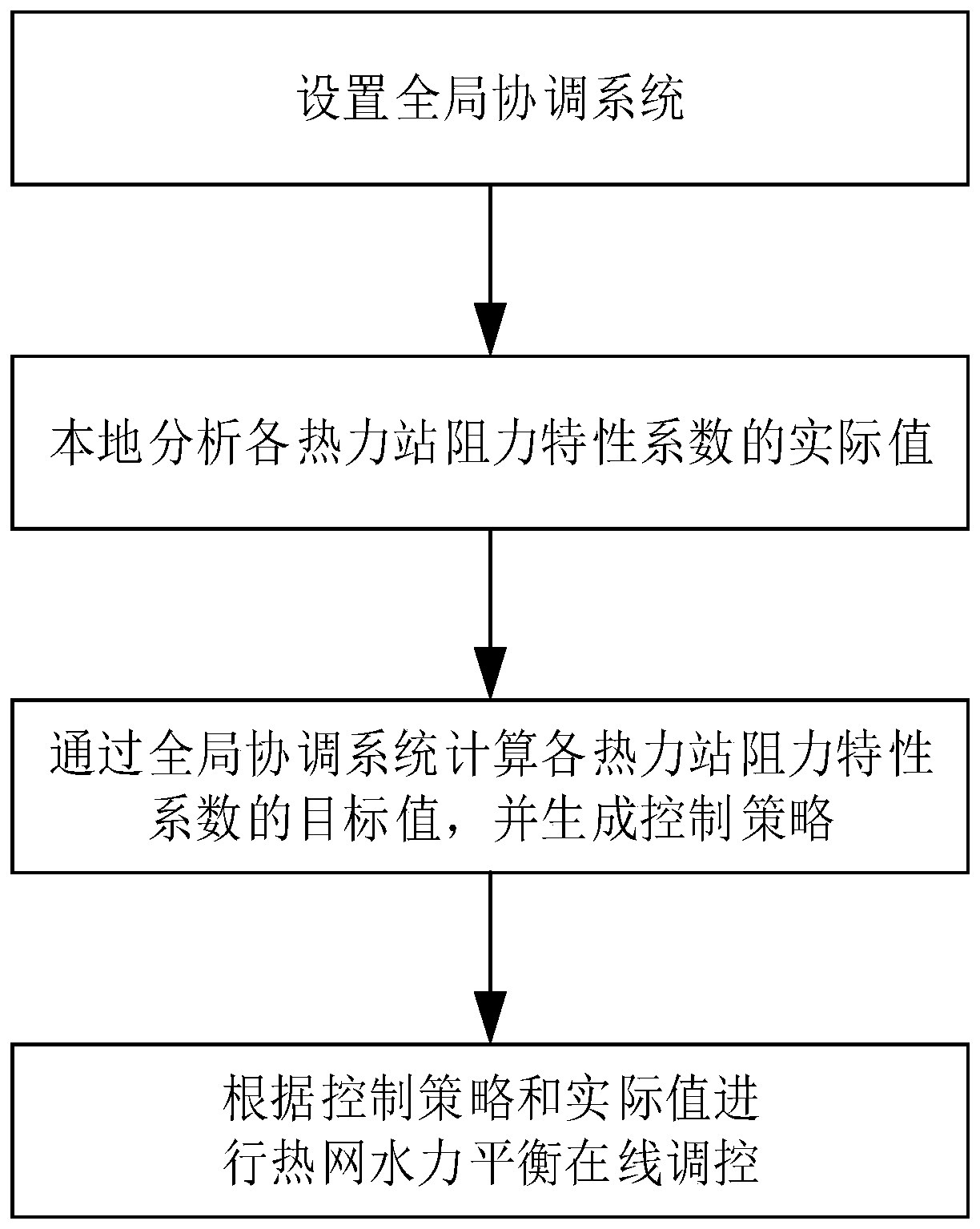

[0079] figure 1 It is a flow chart of the method for adjusting and controlling the hydraulic balance of the heating network based on the resistance characteristics of the thermal station involved in the present invention.

[0080] like figure 1 As shown, the present embodiment 1 provides a method for controlling the hydraulic balance of the heating network based on the resistance characteristics of the heating stations, which is characterized in that it includes: setting up a global coordination system; locally analyzing the actual values of the resistance characteristic coefficients of each heating station; The system calculates the target value of the resistance characteristic coefficient of each thermal station, and generates a control strategy; and conducts online regulation of the hydraulic balance of the heating network according to the control strategy and the actual value; conducts online calculation and analysis of the heating network based on the global coordinatio...

Embodiment 2

[0130] Figure 7 It is a control flow chart of hydraulic balance degree of thermal station i involved in the present invention.

[0131] like Figure 7 As shown, on the basis of Embodiment 1, this Embodiment 2 takes the i-th thermal station at time t as an example for illustration; the global coordination system set on the cloud server reads the latest heat network structure model of the heating enterprise, and then The weather condition parameter U at time t t , T ft , based on the function f, calculate the demand flow q at time t in real time t , and calculate the hydraulic balance μ of the heating network under a single working condition;

[0132] When μt , supply and return water pressure P st ,P rt , demand load Q t and demand flow q t , based on the simulation calculation model function Г of the heating system pipe network, calculate the calculation parameters [q ti ,Δp ti], so as to calculate the target value ζ of the resistance characteristic coefficient of...

Embodiment 3

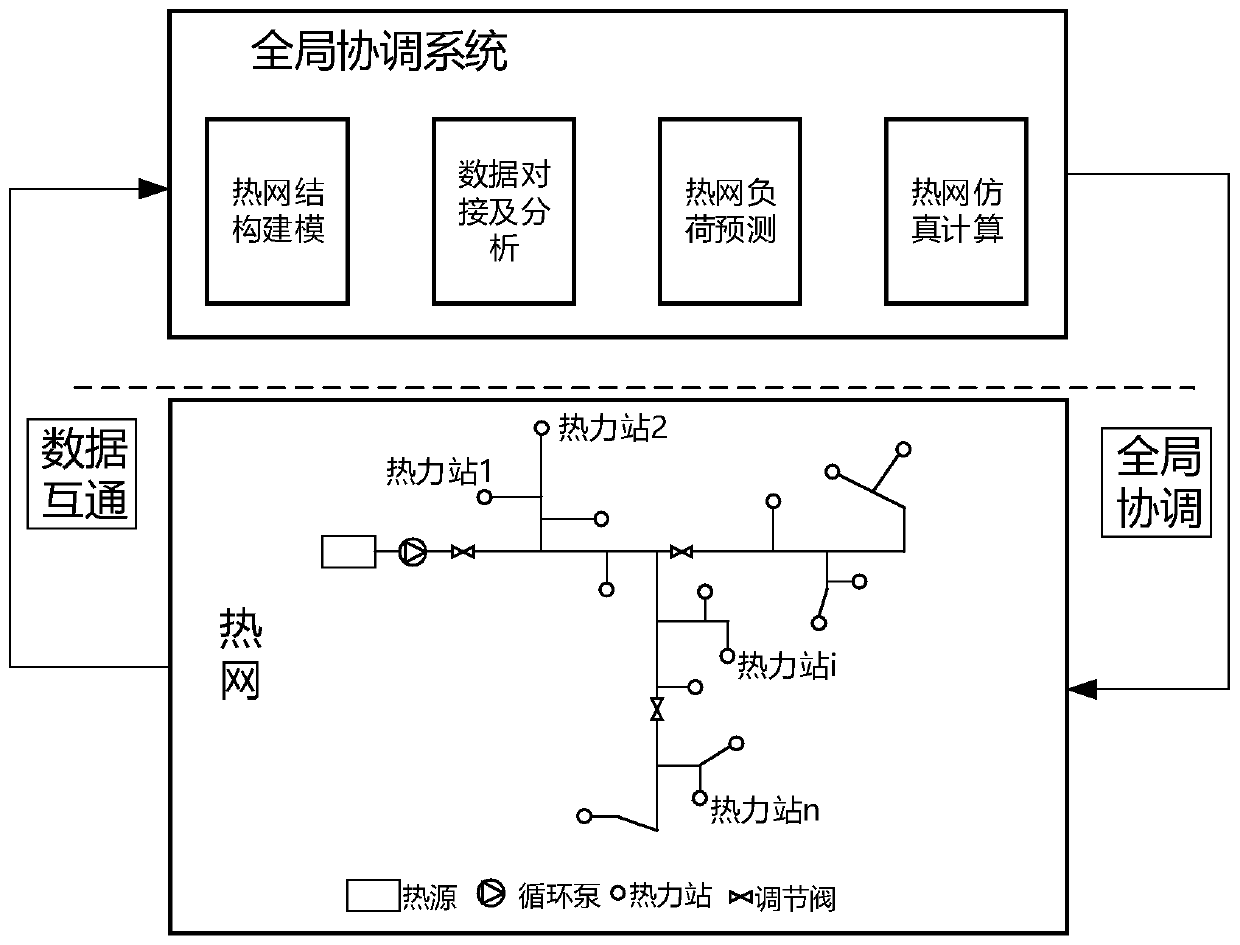

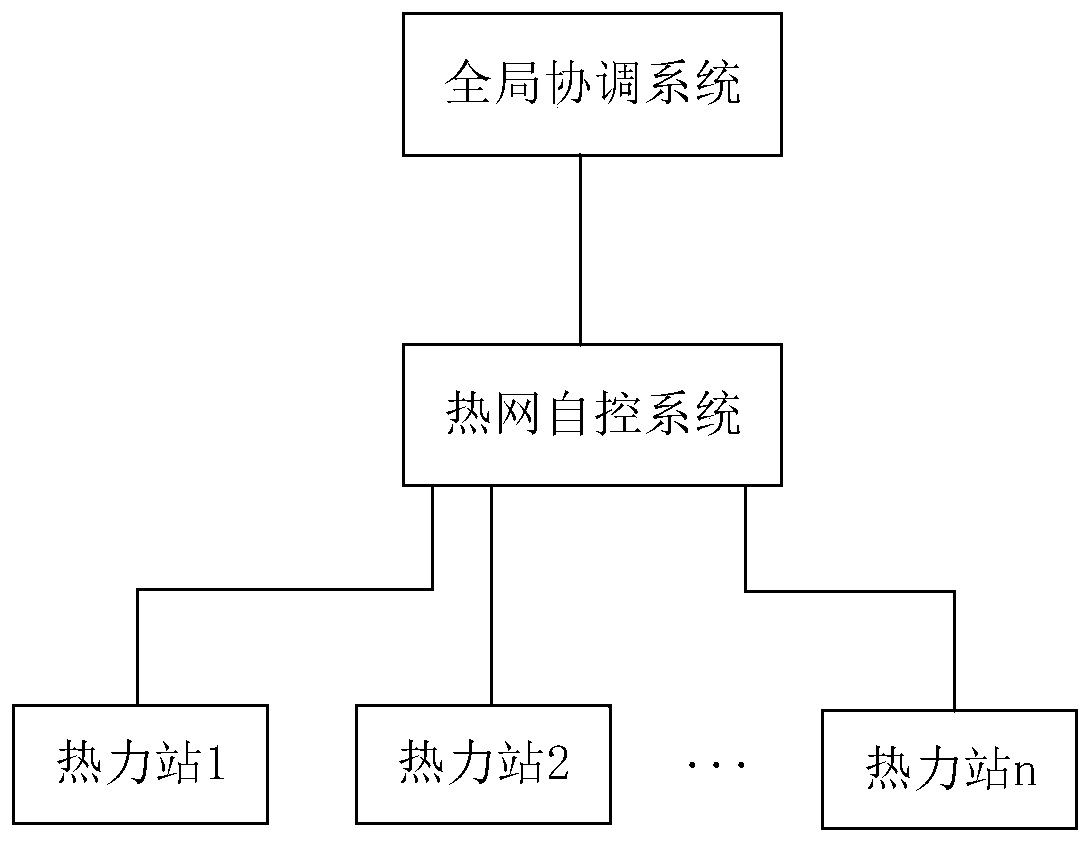

[0137] Figure 8 It is a principle block diagram of the hydraulic balance control system of the heating network based on the resistance characteristics of the thermal station involved in the present invention.

[0138] like Figure 8 As shown, on the basis of Embodiment 1 and Embodiment 2, this Embodiment 3 also provides a heating network hydraulic balance control system based on the resistance characteristics of the thermal station, including: a cloud server and a controller; the controller is set at In the thermal station, and the cloud server is connected to the controller; the cloud server is suitable for setting a global coordination subsystem, and calculates the target value of the resistance characteristic coefficient of each thermal station through the global coordination system, and generates a control strategy; The above-mentioned controller is suitable for analyzing the actual value of the resistance characteristic coefficient of the corresponding thermal station, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com