Method for optimizing structure of laminated glass product

A technology of laminated glass and optimization method, applied in the direction of applying repeated force/pulsation force to test the strength of materials, instruments, electrical digital data processing, etc., can solve the problem that the dynamic failure of laminated glass cannot be effectively overcome, and achieve the optimization of structural form and improvement The effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

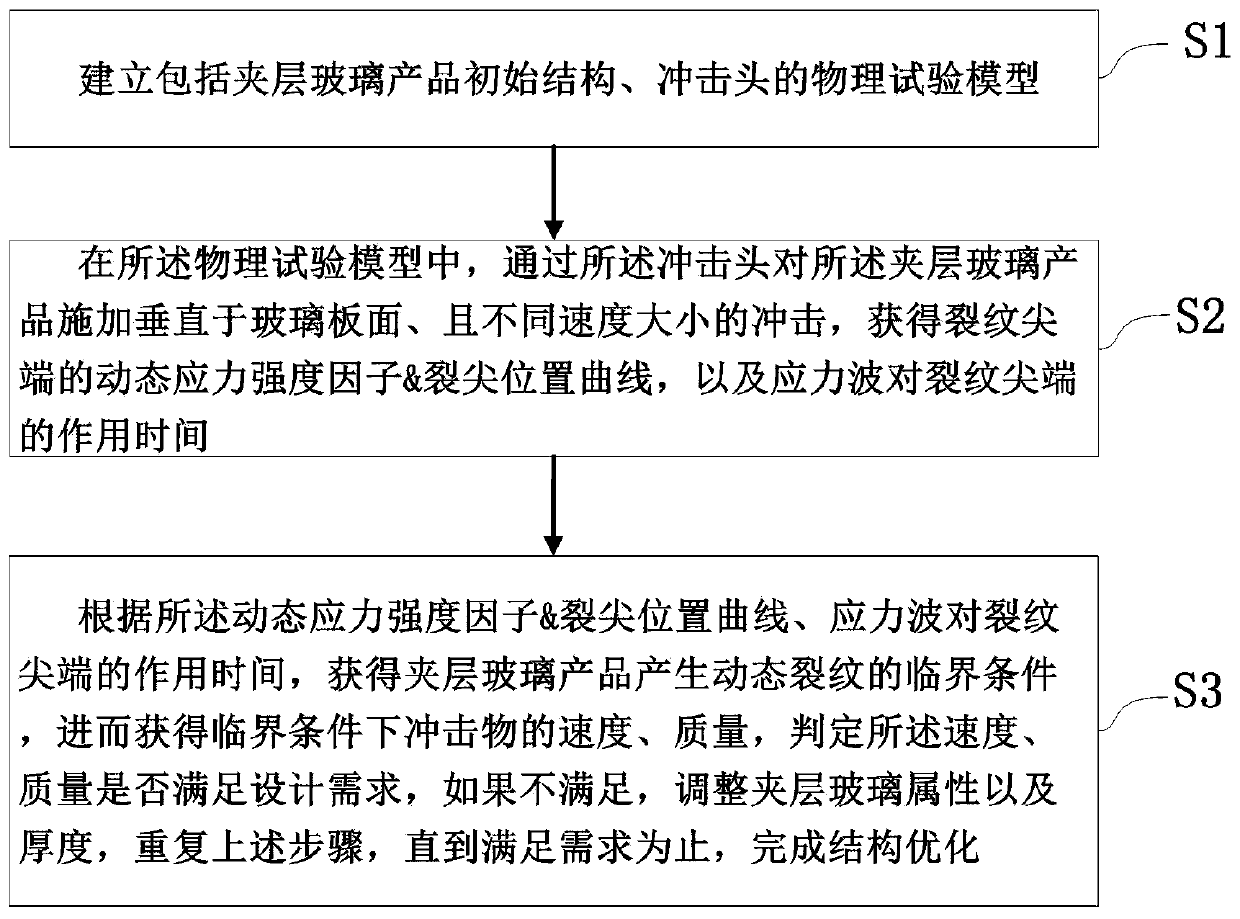

[0069] A specific embodiment of the present invention discloses a method for optimizing the structure of laminated glass products, such as figure 1 shown, including the following steps:

[0070] S1. Establish a physical test model including the initial structure of the laminated glass product and the impact head;

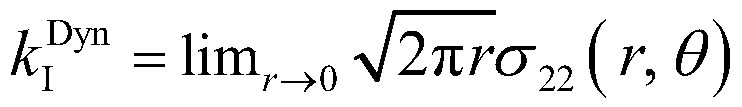

[0071] S2. In the physical test model, apply impacts perpendicular to the glass plate surface and at different speeds to the laminated glass product through the impact head to obtain the dynamic stress intensity factor-crack tip position curve of the crack tip, and The action time of the stress wave on the crack tip;

[0072] S3. According to the dynamic stress intensity factor-crack tip position curve and the action time of the stress wave on the crack tip, obtain the critical condition for the generation of dynamic cracks in laminated glass products, and then obtain the speed and quality of the impacting object under the critical condition, and determine the Whe...

Embodiment 2

[0075] Optimizing on the basis of the structure optimization method of the laminated glass product in Embodiment 1, the step S1 can be further refined into the following steps:

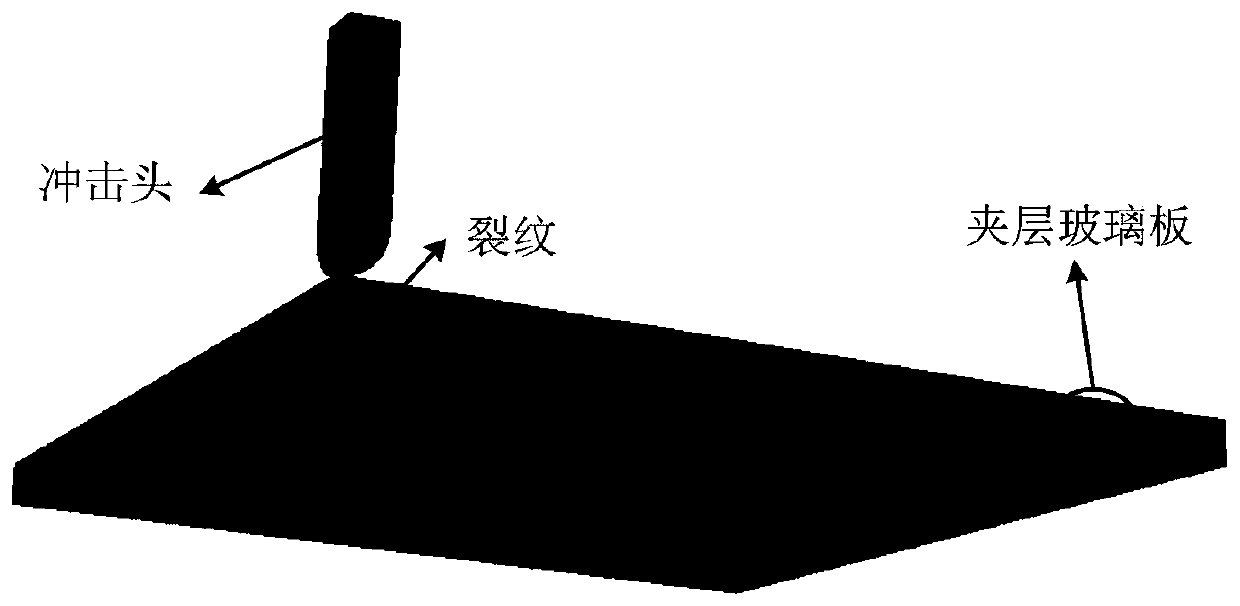

[0076] S11. Obtain the dimensions and material parameters of the initial structure of the laminated glass product, and establish an initial simulation model of the laminated glass product, such as figure 2 shown;

[0077] S12. At a preset position above the laminated glass of the laminated glass product, establish an impact head simulation model to ensure that the impact direction is perpendicular to the surface of the laminated glass;

[0078] S13. Set the impact space, establish the physical test model including the initial simulation model of the laminated glass product, the impact head simulation model, and the impact space, divide the grid, and ensure that the two glass layers and the middle layer of the laminated glass are respectively provided with at least three layers of mesh grid unit to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com