Water pressure resistance test device and test method for seam sealing glue

A technology of hydrostatic testing and water-stop glue, applied in measuring devices, mechanical devices, instruments, etc., can solve the problems of complicated operation, inability to simulate aging environment, poor accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

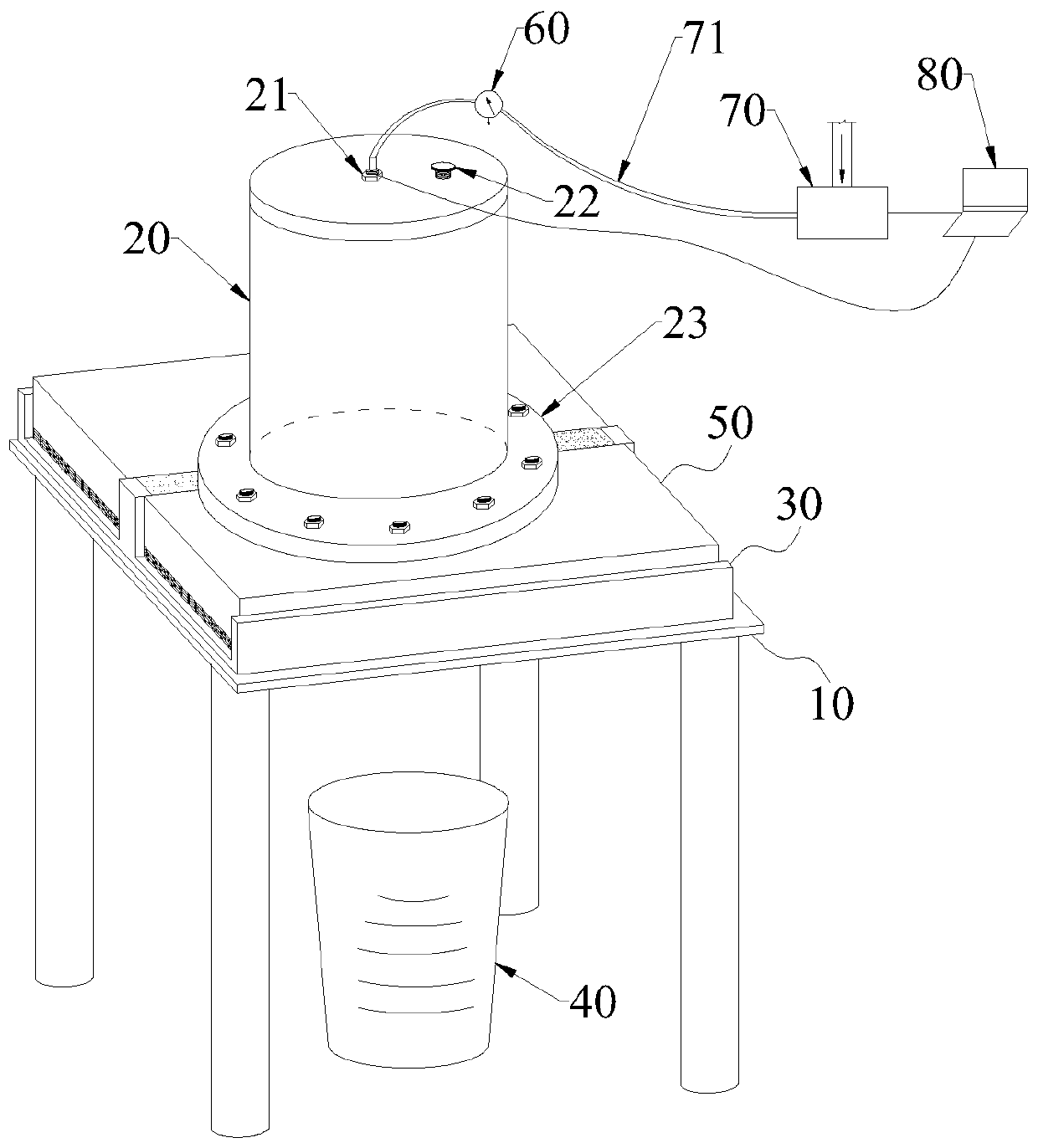

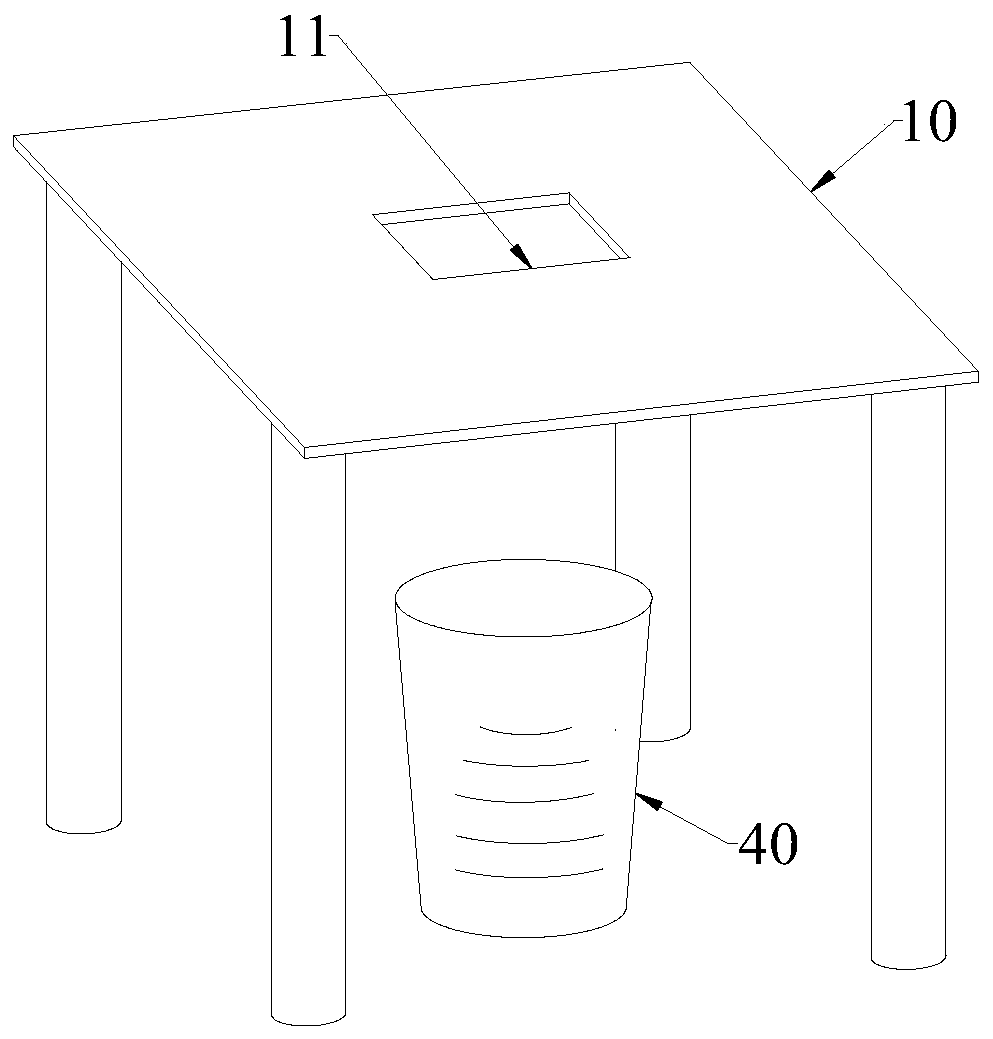

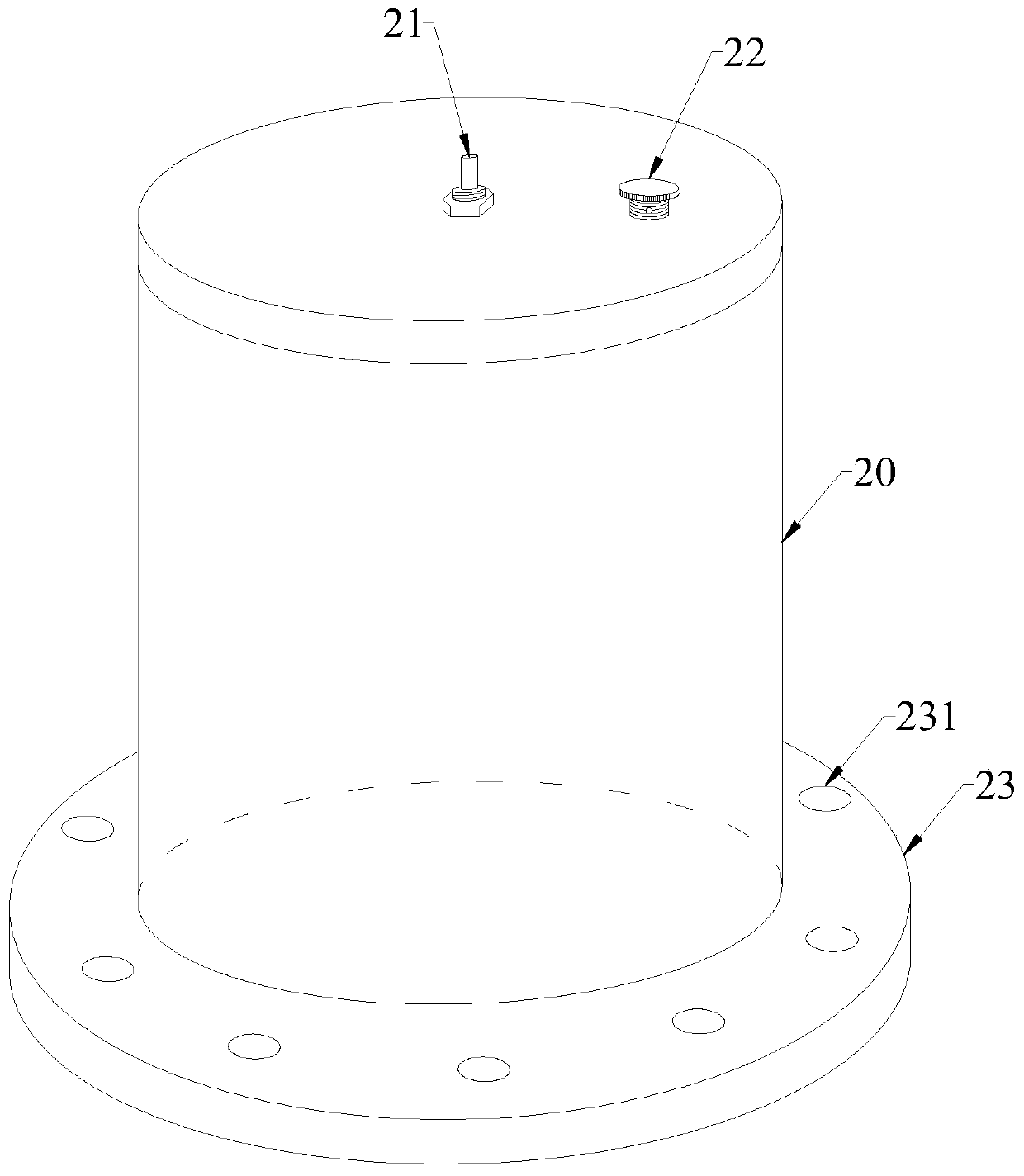

[0046] Such as Figure 1~6As shown, the described anti-water pressure test device for seam sealing glue includes a test bench 10, a concrete sample layer 50 arranged above the test bench 10, a fixing frame 30 for fixing the concrete sample layer 50, and a concrete sample layer 50 arranged on the concrete The transparent pressure barrel 20 above the sample layer 50, the water injection pressurization equipment, and the measuring cup 40, one end of the transparent pressure barrel 20 is open, and the open end of the transparent pressure barrel 20 is called the mouth of the transparent pressure barrel 20. The transparent pressure The other end of the barrel 20 is closed, and the closed end of the transparent pressure barrel 20 is called the bottom of the transparent pressure barrel 20. The bottom of the transparent pressure barrel 20 faces upward, and the mouth of the transparent pressure barrel 20 is provided with a Flange 23, said flange 23 is in sealing connection with the top ...

Embodiment 2

[0057] The test method of the seam sealing glue anti-hydraulic test device comprises the following steps:

[0058] Step a, clean the sides of the two rectangular concrete slabs 51 and place them inside the fixed frame 30 respectively; four plastic slabs 90 are respectively placed on the bottom of the two rectangular concrete slabs 51, and the thickness of the plastic slabs 90 is 3mm.

[0059] Step b. Use water-stop glue to make a water-stop adhesive layer 52 at the position between the two concrete slabs 51. During the production process of the water-stop adhesive layer 52, it should be filled in layers, and compacted and scraped with a scraper to eliminate air bubbles as much as possible. The surface is scraped and smoothed.

[0060] Step c. Put the formed waterproof adhesive layer 52 together with the fixed frame 30 into a standard curing room with a temperature of 23±2°C and a relative humidity of 50±5% for 7 days, and prepare 3 test pieces for each group.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com