Single-side hub motor based on power generation tire

A hub motor and tire technology, applied to synchronous motors with stationary armatures and rotating magnets, motors, tire parts, etc., can solve problems such as slow process, reduced battery power storage capacity, and influence on consumers' car purchase choices. Achieve the effects of reducing power loss, facilitating maintenance and replacement, and saving storage links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

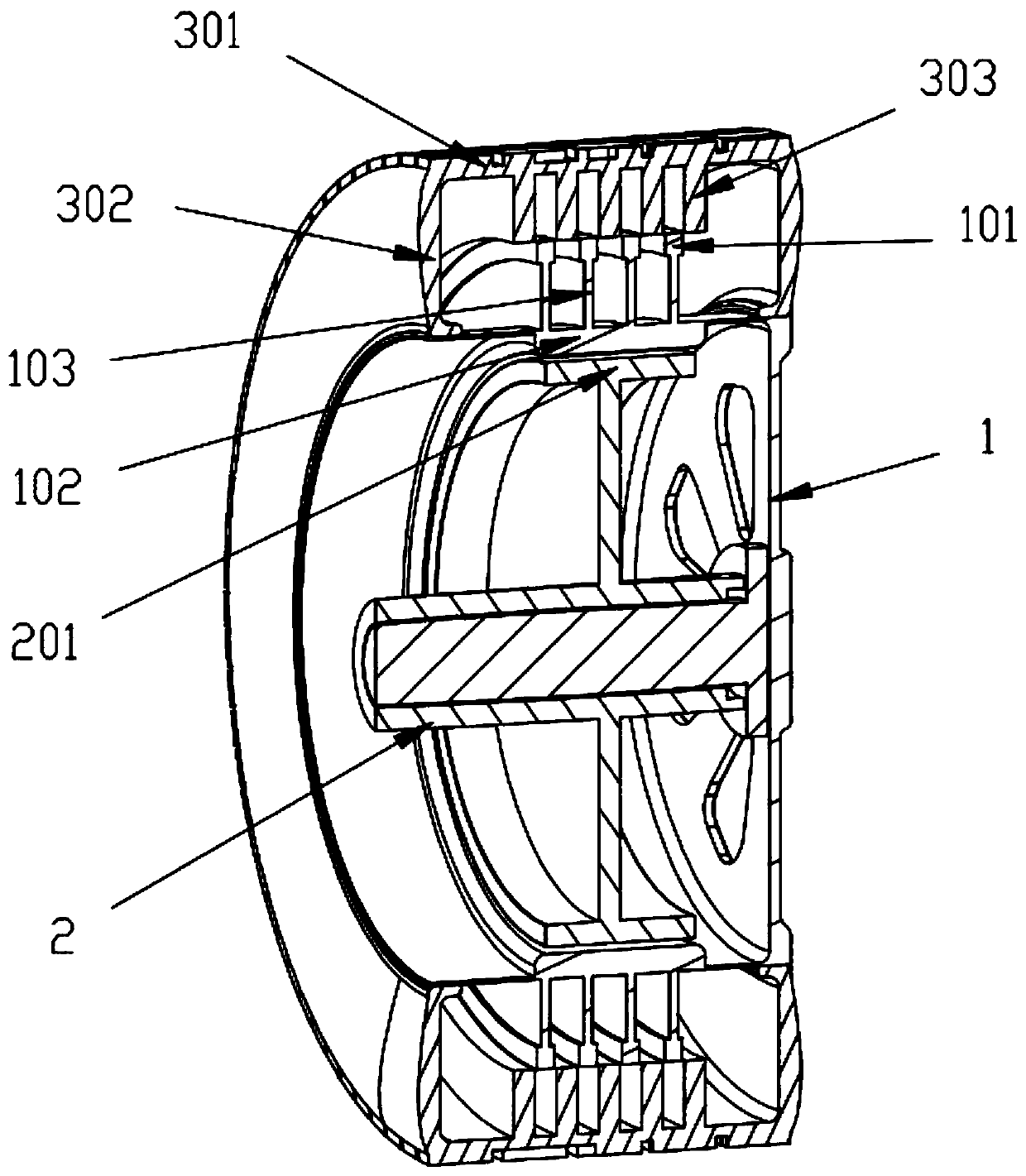

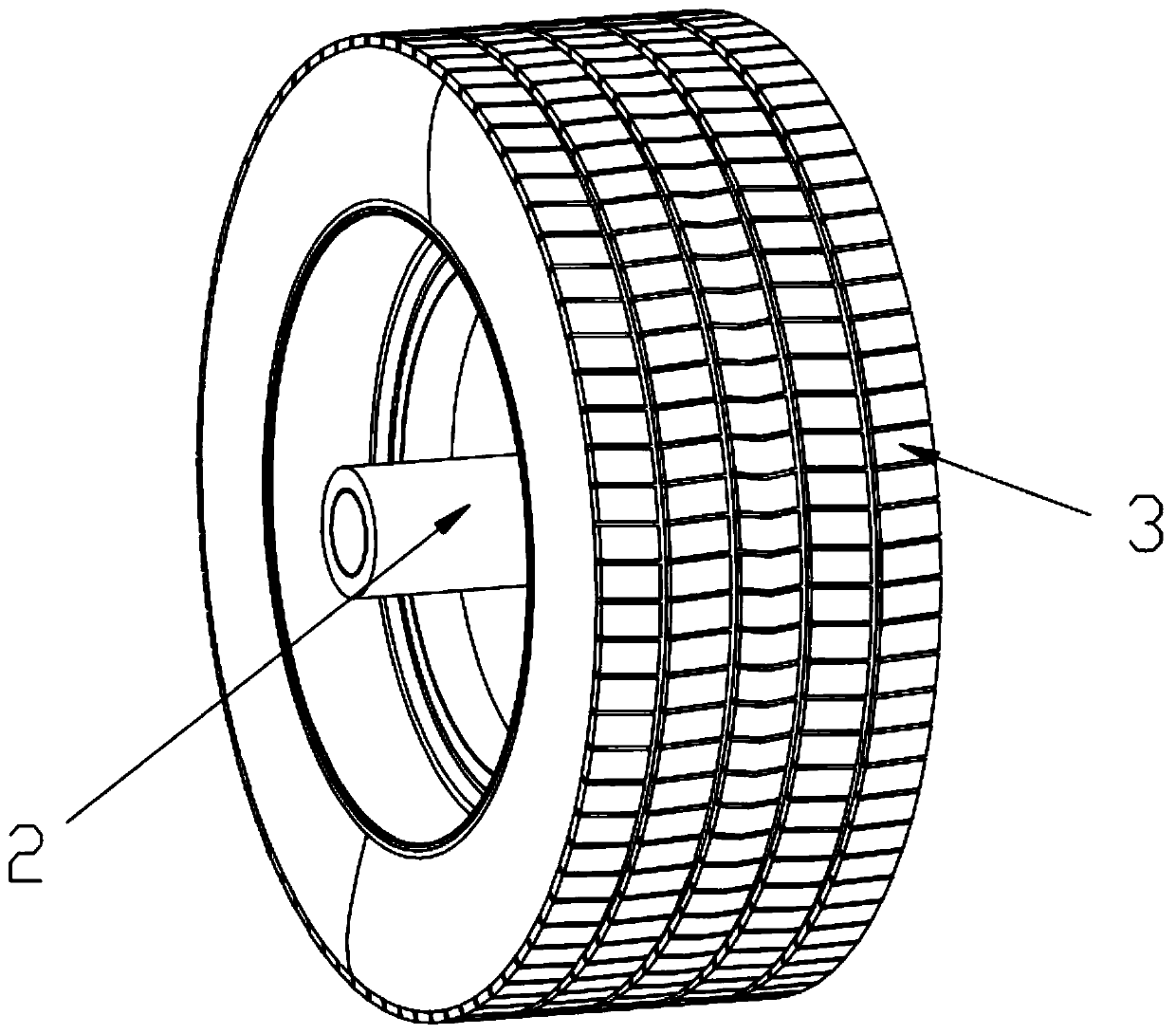

[0014] With reference to the accompanying drawings, a unilateral hub motor based on power generation tires includes a hub 1, a hub motor 2 arranged on one side of the hub 1, and a tire 3 arranged on the outer ring of the hub 1. The hub motor 2 does not rotate with the hub 1 Turning, the tire 3 is a hollow structure, and the tire 3 includes an upper tire surface 301 opposite to the outer surface of the outer ring of the wheel hub 1 and a side tire surface 302 arranged on both sides of the upper tire 301 surface and socketed with the wheel hub 1. The inner side of the upper tire surface 301 is provided with permanent magnets 303 along the inner wall of the upper tire surface 301. The number of the permanent magnets 303 is multiple, and the permanent magnets 303 are arranged at intervals along the width direction of the inner side of the upper tire surface 301. A plurality of sets of copper coils 101 are arranged on the outer surface of the ring, and the gaps between the copper co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com