Device and control method for directly drying sludge by wind power generation

A technology for wind turbines and sludge, applied in dehydration/drying/thickened sludge treatment, program control, computer control, etc., can solve the problems of high technical requirements for grid connection, high cost, energy loss, etc., to ensure drying quality, increase or decrease drying time, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

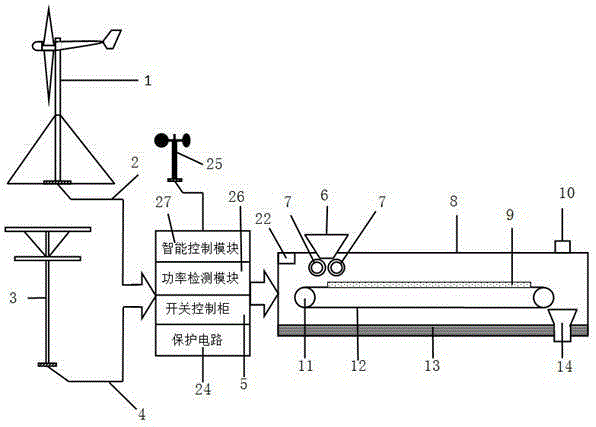

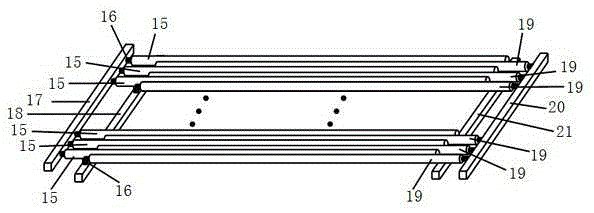

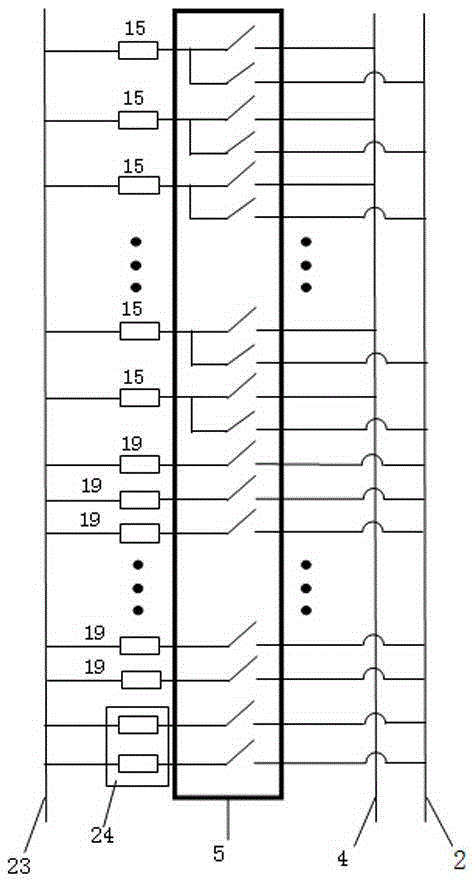

[0017] figure 1 It is a schematic diagram of the overall structure of the present invention. The present invention adopts a power supply mode in which the wind power generating set 1 mainly generates electricity and the grid 3 supplies electricity as an auxiliary. The wind power generating set 1 and the power grid 3 are respectively connected to the switch control cabinet 5 through the wind power generator output cable 2 and the power grid cable 4 for use by various components of the device. The top of the sludge drying chamber 8 is provided with a sludge feed port 6 and a waste gas discharge port 10, and two rollers 7 are installed directly below the sludge feed port 6, which can compress the sludge 9 into flakes and spread it on the belt. 12, increase the sludge and air contact surface. A temperature detection module 22 is installed on the top of the sludge drying chamber 8 to detect the temperature of the drying chamber 8 at all times. A drying heating device 13 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com