Power tool

A technology of power tools and power parts, which is applied in the direction of manufacturing tools, metal processing equipment, portable motorized devices, etc., and can solve problems such as carbon brush wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

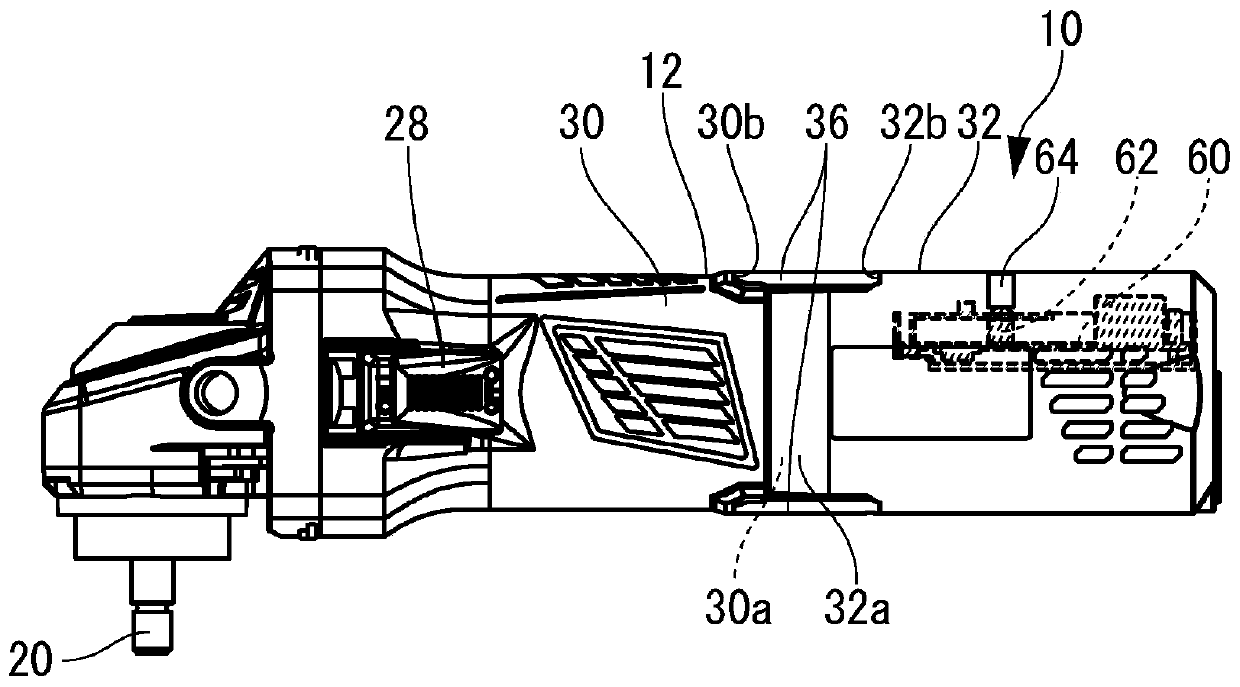

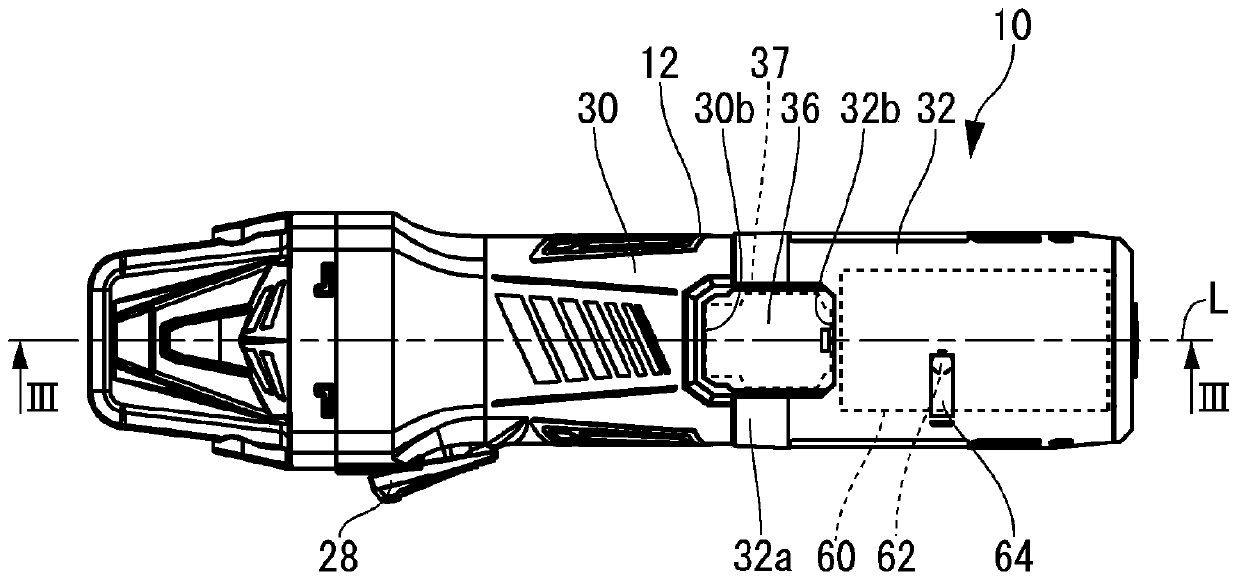

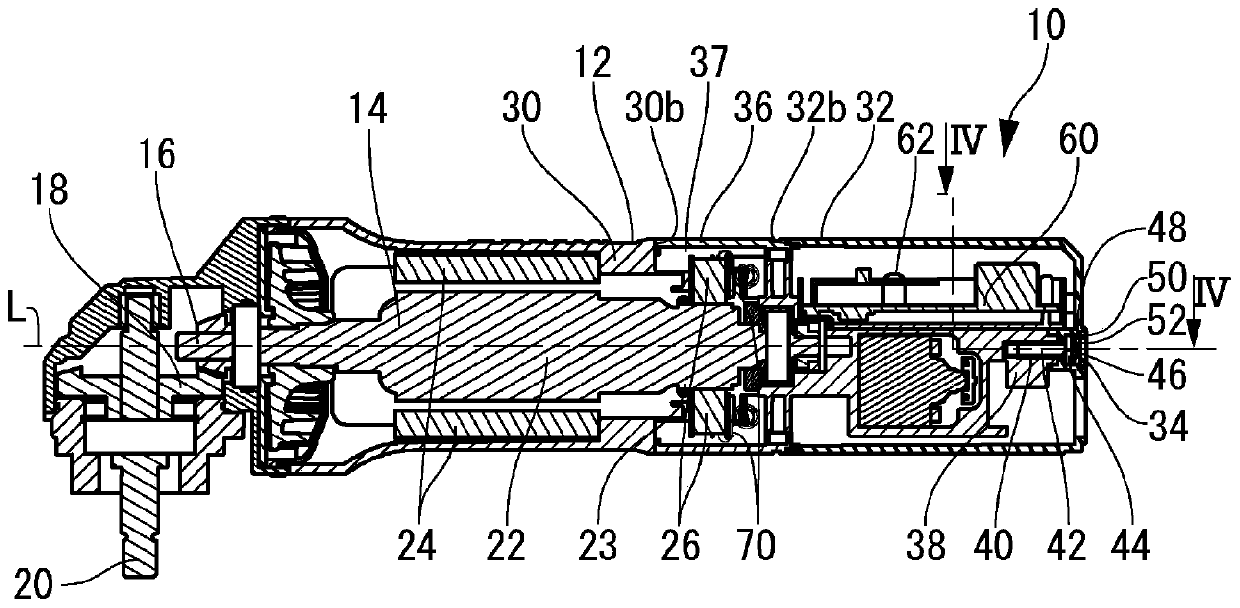

[0043] Such as Figure 1 to Figure 3 As shown, a power tool 10 according to an embodiment of the present invention is an electric power tool including a commutator motor 14 as a power part in a casing 12 . On the tool output shaft 20 drivingly coupled to the rotation output shaft 16 of the commutator motor 14 via the bevel gear 18, necessary members such as a disc-shaped polishing pad are attached according to the application.

[0044] Such as image 3 As shown, the commutator motor 14 has: a rotor 22, which is installed to be rotatable relative to the housing 12; a stator 24, which is arranged around the rotor 22 and fixed to the housing 12; Contact with the commutator 23 of the rotor 22. A switch 28 is attached to the casing 12 , and driving of the commutator motor 14 is started / stopped by operating the switch 28 . The brushes 26 slide against the high-speed rotating commutator 23 and thus gradually wear out. Therefore, after using the power tool 10 for a certain period ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com