Deep sea culture ship

A deep-sea and hull technology, applied in the field of deep-sea breeding ships, can solve the problems of long manufacturing cycle, slow offshore water flow, difficult to use resources, etc., and achieve the effects of reducing water impact load, improving the stability of the center of gravity, and improving driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

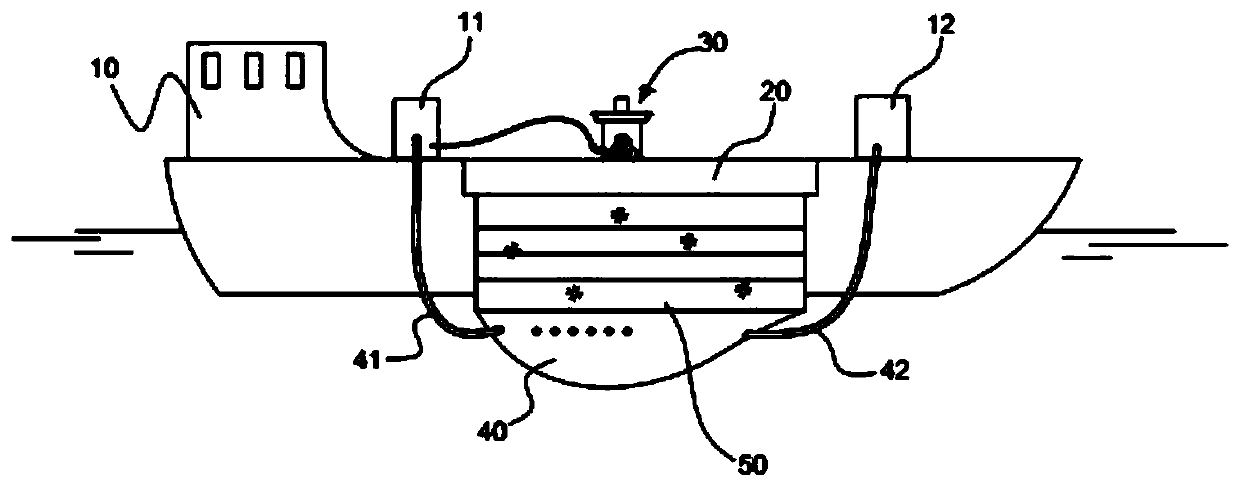

[0026] see Figure 1-5 as shown,

[0027] A deep sea culture vessel, comprising:

[0028] Hull 10, side panels 20 are horizontally connected to both sides of the hull 10,

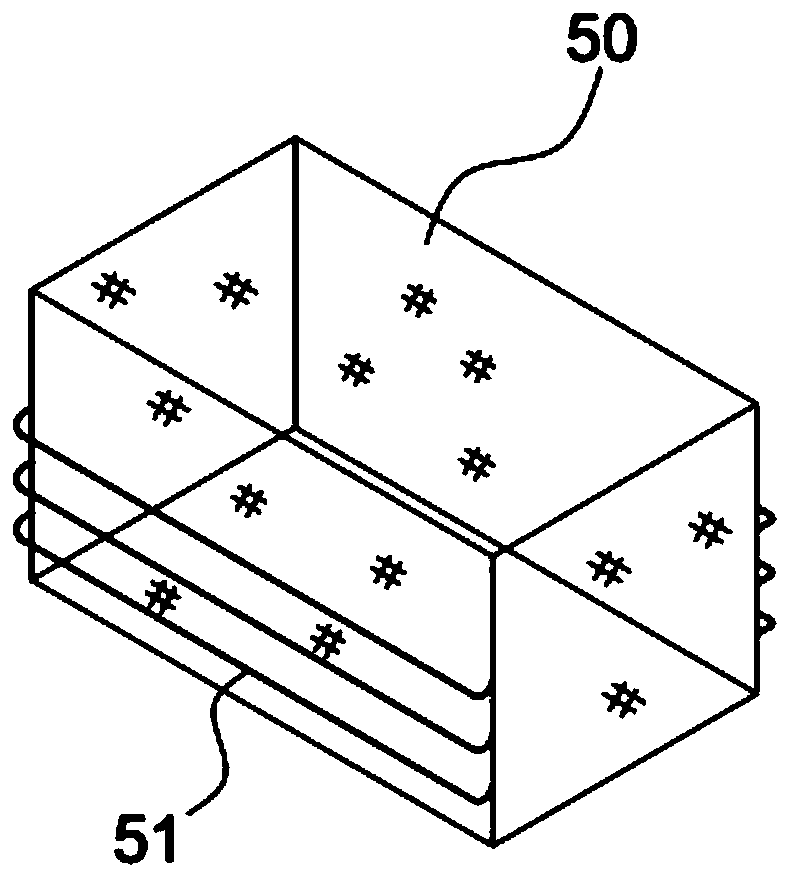

[0029] Cultivation cage 50 is fixedly connected to the side plate 20 below, and the bottom surface of cultivation cage 50 is lower than the waterline of hull 10,

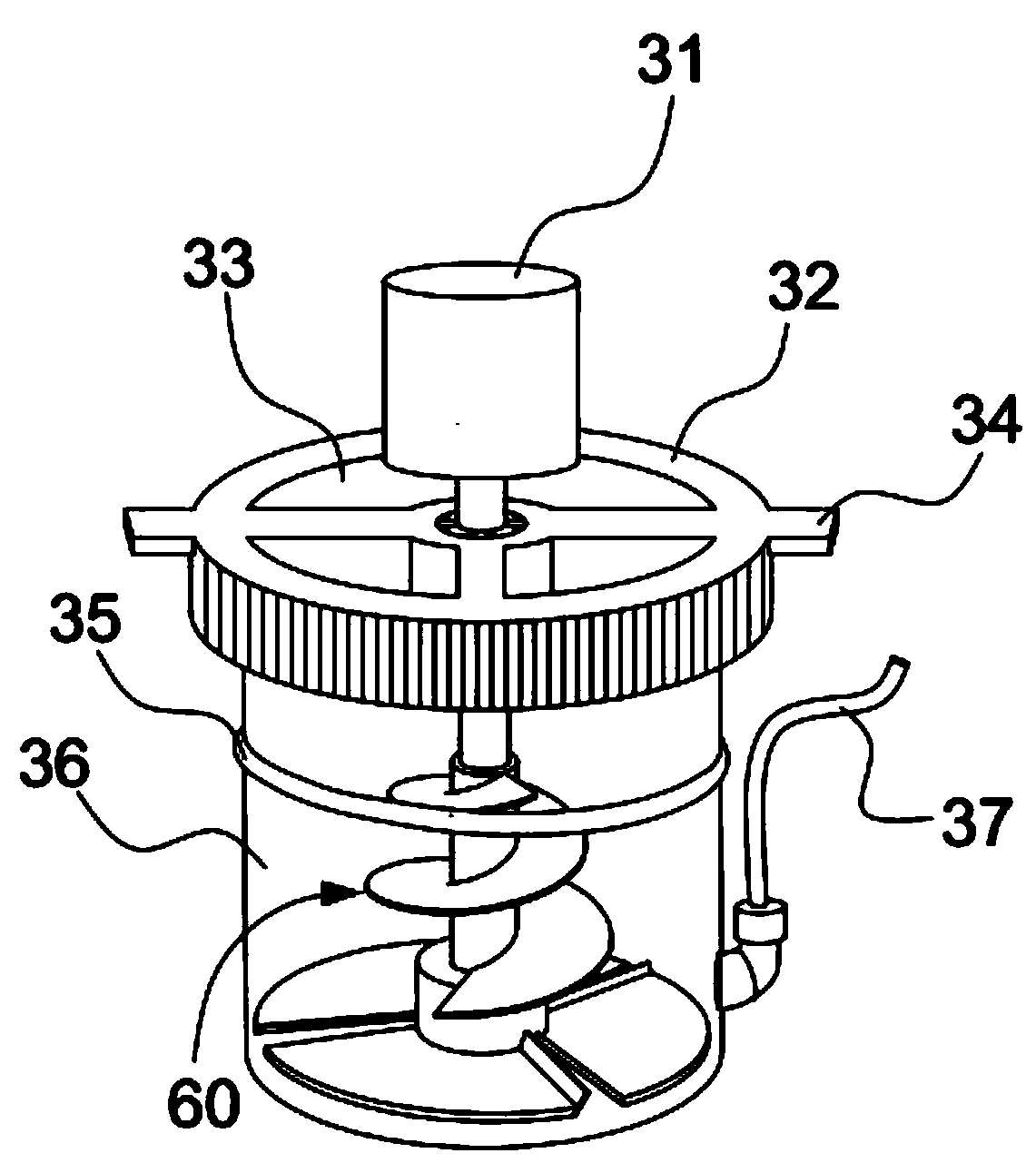

[0030] Wherein culture cage 50 bottoms are fixedly connected with buoyancy control assembly 40, and buoyancy control assembly 40 comprises the buoyancy box 43 of sealing, and buoyancy box 43 is connected with the water pump 12 on the hull 10 by the second connection pipe 42, is also provided with in the buoyancy box 43 The first air pipe 44, the ports at the two ends of the first air pipe 44 are respectively arranged outside the two sides of the buoyant tank 43, and the first air pipes 44 in the buoyant tank 43 are communicated by the first connecting pipe 41, and the first connecting pipe 41 also Connect with the air pump 11 on the hull 10. ...

Embodiment 2

[0040] When a kind of deep-sea breeding ship of the present invention is actually used: by affixing the side plates 20 on both sides of the hull 10, and connecting the culture net cage 50 on the bottom surface of the side plate 20, it is necessary to ensure that the bottom surface of the culture net cage 50 is lower than the waterline of the hull 10. If so, the horizontal position height of the side 20 can be reduced to ensure that the culture net cage 50 is in the water as a whole, and through the above-mentioned improvement method, it can be realized that ordinary ships have the cage culture function and carry out deep-sea culture. When the cultivation amount of the cultured species in the cultured net cage 50 is less or in the early stage of cultivation, the water body can be injected into the buoyancy tank 43 to improve the stability of the center of gravity of the cultured net cage 50, and ensure that the sailing of the hull 10 is stable. The growth of the growth or the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com