Stainless steel double-clamping-pressure adjustable direct joint and tee joint production die

A technology of stainless steel clips and stainless steel, applied in the direction of pipes/pipe joints/fittings, perforating tools, forming tools, etc., can solve the problems of complex processing technology and low degree of automation, achieve strong universality, reduce labor costs, and save production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

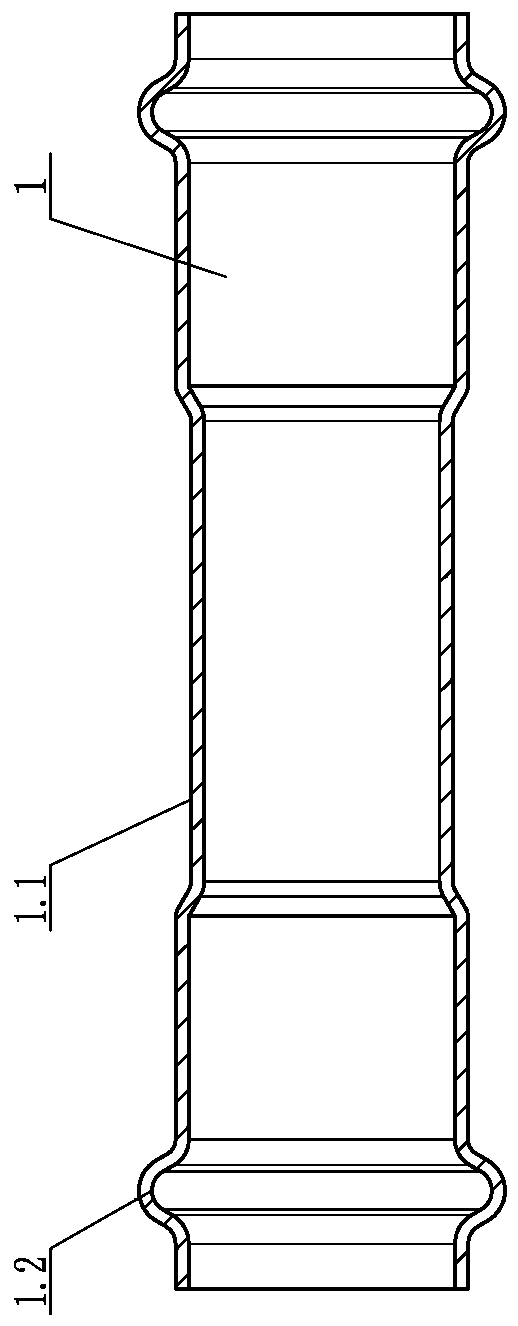

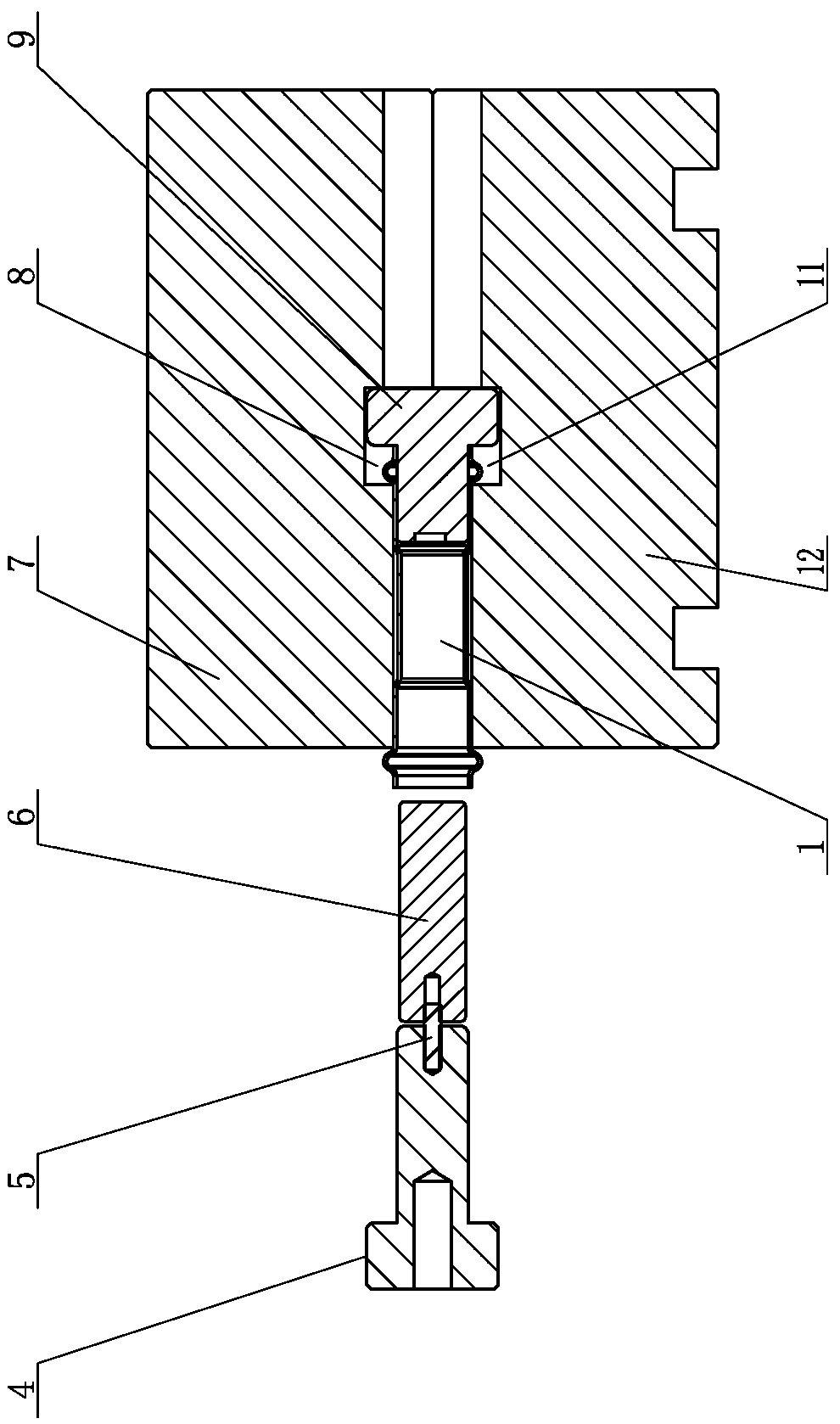

[0048] Such as figure 2 As shown, in this embodiment, the functional body is an elastic body, and the elastic body is used to push up the concave ring in the middle of the stainless steel pressing pipe fitting to a pipe body having the same diameter as the connecting pipes on both sides. The invention adopts the elastic body for jack-up processing, which can ensure the molding quality without damaging the inner wall of the pipe fitting, and the middle part of the formed pipe body fully fits the pipe body forming cavity, and there is no need for secondary shaping operations in the later stage.

[0049] The cross-sectional diameter of the spacer positioning cavity is larger than the cross-sectional diameter of the pipe body forming cavity; the axial section of the top-mounted spacer is "T"-shaped, and the top-mounted spacer is inserted into the right end of the stainless steel clamping pipe. The small-diameter end, the right-end annular protrusion of the stainless steel clampin...

Embodiment 2

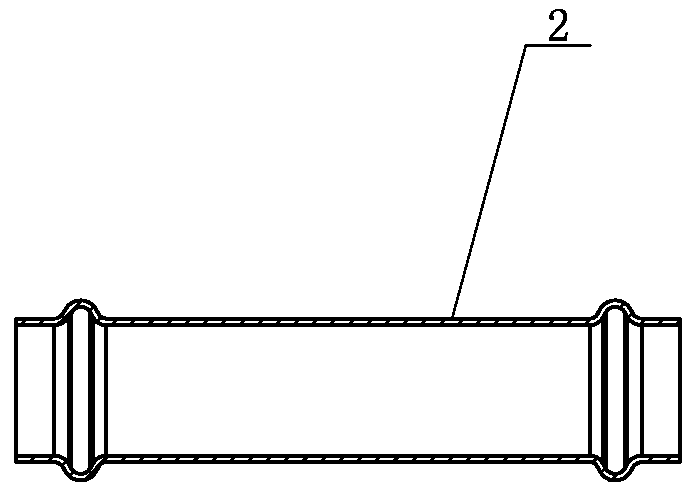

[0056] This embodiment is the quality inspection steps after processing the stainless steel double clamping adjustable straight head in the first embodiment. The horizontal punching pin is cylindrical, and its outer diameter is the same as the inner diameter of the middle section after the stainless steel clamping pipe is processed into an adjustable straight head; the outer wall of the horizontal punching pin is smooth without scratches.

[0057] The quality inspection process of the stainless steel double-press adjustable straight joint includes the following steps:

[0058] After completing the step (2) in the production process of the stainless steel double clamping adjustable straight head, the elastic body is removed from the horizontal punching pin, and then the horizontal punching pin driving device drives the horizontal punching pin to insert into the stainless steel clamping pipe and then pull it out. Observe whether there are scratches on the outer surface of the ho...

Embodiment 3

[0062] Such as Figure 5 As shown, in this embodiment, on the basis of retaining the structure of the upper molding die and the lower molding die described in Embodiment 1, a vertical punching hole is opened on the upper molding die. vertical punching pins are arranged in the vertical punching holes, and the vertical punching pin driving device is connected above the vertical punching pins.

[0063] A spacer extension block is installed at the small diameter end of the top-mounted spacer block, and a spacer slot is provided at the bottom of the spacer extension block.

[0064] The production process of the stainless steel double clamping adjustable tee joint includes the following steps:

[0065] (1) Separate the molding upper mold and the lower molding mold; install the pad extension block on the small diameter end of the top mounting pad, insert the small diameter end of the top mounting pad block and the pad extension block on the right end of the stainless steel compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com